Biological nanometer magnetite, and preparation method and application thereof

A bio-nano, magnetite technology, applied in biochemical equipment and methods, microorganism-based methods, microorganisms, etc., can solve the problems of thermodynamic instability, development and application limitations, reduction in reducing ability, etc. The effect of eliminating efficiency and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Enrichment and purification culture of embodiment 1 iron-reducing bacteria

[0054] Streak the Shewanella onesidensis MR-1 (purchased from the China Marine Microorganism Culture Collection Management Center) preserved at -80°C on an LB plate, and cultivate overnight at 30°C; take a single colony and put it into the liquid In LB medium, cultivate at 30°C for 16h; transfer to new liquid LB medium at 1% (v / v) inoculum size, and culture at 30°C at 180rpm for 16h. Centrifuge the cultured bacterial solution at 5000rpm for 5min, wash and centrifuge with sterile water, repeat 3 times, and finally resuspend the bacterial suspension to the required concentration (10 10 cells / mL) for later use.

[0055] Among them, the preparation of LB liquid culture medium is to add tryptone (tryptone) 10g, yeast extract (yeast extract) 5g, NaCl 10g in 950mL deionized water, shake the container until the solute is dissolved; dilute to 1L with deionized water, 121 ℃ autoclave for 20min. When p...

Embodiment 2

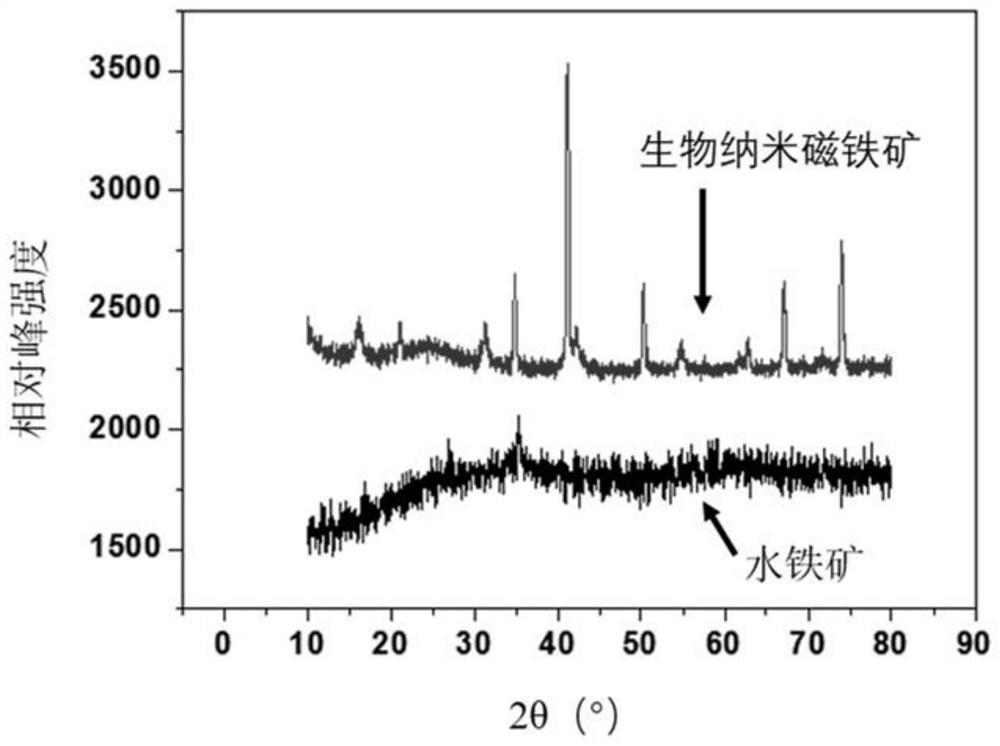

[0056] The synthesis of embodiment 2 ferrihydrite

[0057] First prepare 0.4mol / L FeCl 3 .6H 2 O solution and 1mol / L NaOH solution; in the case of vigorous and uniform stirring, NaOH solution was added dropwise at a constant speed (0.5mL / s) to the FeCl contained in a high-density polyethylene container. 3 Solution, when the pH is close to neutral, the dropping speed should be slowed down until the pH reaches 7.0 and a thick dark red ferrihydrite suspension is formed; then the suspension is allowed to age for 4-6 hours, and the pH will be slightly lower at this time. Decrease (<1pH); after re-adjusting the pH to 7.0, centrifuge the suspension at 7000rpm and 4°C for 10min, pour off the supernatant, add sterilized ultrapure water and stir to resuspend evenly, then repeat the centrifugation for 7 After about two times until the concentration of chloride ion in the ferrihydrite suspension is lower than 1mmol / L, the ferrihydrite whose iron concentration is 200mmol / L is obtained. ...

Embodiment 3

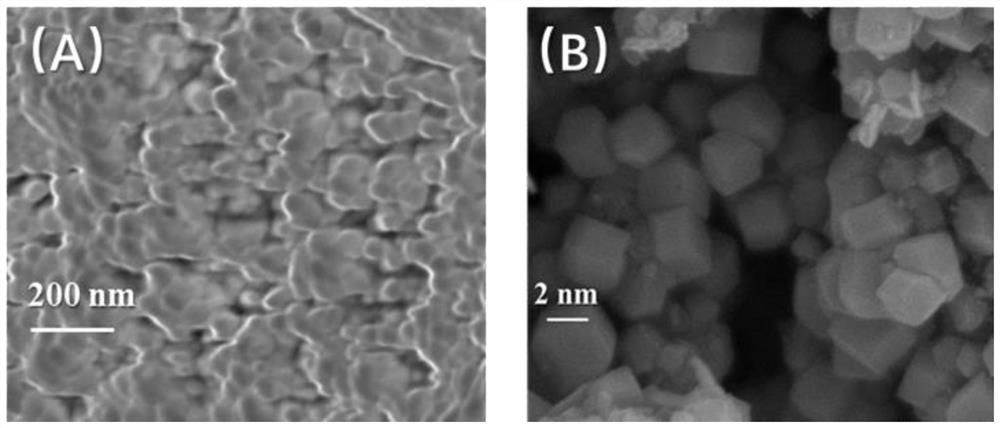

[0058] The preparation of embodiment 3 bionano magnetite

[0059] Get the ferrihydrite that 25mL embodiment 2 obtains and place in the anaerobic bottle of 250mL, the bacterium suspension that obtains in 2mL embodiment 1 is inoculated in ferrihydrite, and adding final concentration is 20mmol / L lactic acid as required by microorganism Electron donor, while using a final concentration of 25mmol / L sodium bicarbonate buffer to adjust the pH value of the system to 7.0, the final volume of the reaction system obtained is 200mL, the final concentration of iron in ferrihydrite is 25mmol / L, and N 2 / CO 2 The mixed gas was deoxygenated for 30 minutes, and kept in a constant temperature anaerobic box at 25°C for 7 to 8 days in the dark to obtain a black suspension; the suspension was separated by centrifugation (10000rpm, 15min), the supernatant was removed, and reserved Black precipitate; wash the magnetite precipitate repeatedly with ultrapure water three times, centrifuge (10000rpm, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com