Interior material having deodorant, antimicrobial surface layer and production method thereof

A technology for interior materials and a manufacturing method, applied in the field of interior materials, can solve problems such as poor anti-fungal effect, and achieve the effect of preventing microbial contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

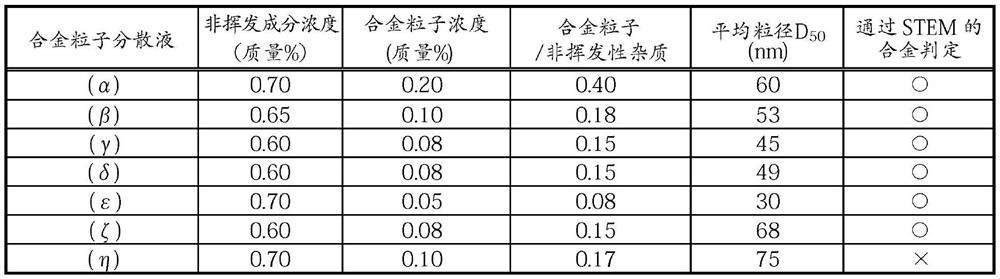

Examples

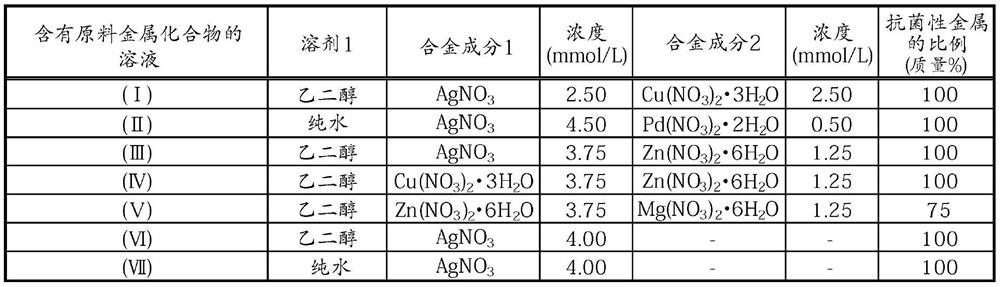

preparation example Construction

[0089] As a method for preparing peroxotitanic acid solution, an alkaline substance is added to a raw material titanium compound in an aqueous dispersion medium as titanium hydroxide, and impurity ions other than the contained metal ions are removed, and an over A method in which hydrogen peroxide is further formed into peroxotitanic acid; it may also be, after hydrogen peroxide is added to the raw material titanium compound, an alkaline substance is added to form peroxotitania hydrate; Impurities, and a method of adding hydrogen peroxide in one step to form peroxotitanic acid.

[0090] Here, as a raw material titanium compound, for example, inorganic acid salts such as titanium chloride, nitrate, and sulfate; organic acid salts such as formic acid, citric acid, oxalic acid, lactic acid, and glycolic acid; Titanium hydroxide or the like which is hydrolyzed and precipitated in an aqueous solution; one of these may be used or a combination of two or more may be used. Among them...

Embodiment 1

[0175]

[0176] After diluting 36% by mass of titanium (IV) chloride aqueous solution 10 times with pure water, 10% by mass of ammonia water was gradually added for neutralization and hydrolysis to obtain a titanium hydroxide precipitate. At this point the pH of the solution was 9. The resulting precipitate was deionized by repeated addition of pure water and decantation. After this deionization treatment, 35% by mass of hydrogen peroxide water was added to the titanium hydroxide precipitate, so that H 2 o 2 / Ti (molar ratio) was 5, and then the mixture was stirred at room temperature for a day and night to fully react, and then a yellow transparent peroxotitanic acid solution (a) was obtained.

[0177] Add 400mL of peroxotitanic acid solution (a) into an autoclave with a volume of 500mL, and conduct a hydrothermal treatment at 130°C and 0.5MPa for 90 minutes, and then adjust the concentration by adding pure water to obtain the oxidized Titanium particle dispersion (A) (n...

Embodiment 2

[0187]

[0188] Except that tin (IV) chloride is added / dissolved in the titanium (IV) chloride aqueous solution of 36 mass % in the mode that Ti / Sn (molar ratio) is 20, other are the same as the preparation method of embodiment 1, and then A yellow transparent peroxotitanic acid solution (b) was obtained.

[0189] 400 mL of peroxotitanic acid solution (b) was added into an autoclave with a volume of 500 mL, and it was subjected to hydrothermal treatment at 150° C. and 0.5 MPa for 90 minutes. Then, the concentration was adjusted by adding pure water to obtain a titanium oxide particle dispersion (B) (1.0% by mass of non-volatile matter concentration) (Table 1).

[0190]

[0191] In addition to using pure water as a solvent, silver nitrate is dissolved at a concentration of 4.50 mmol / L as Ag, and palladium nitrate dihydrate is dissolved at a concentration of 0.50 mmol / L as Pd. Except for the solution (II) (Table 2), the preparation method was the same as that of Example 1 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com