U-rib internal supine welding method based on high-viscosity and high-toughness flux-cored welding wire

A technology of flux-cored welding wire and welding method, applied in the field of steel structure welding, can solve the problems affecting the welding seam forming, falling, welding meat falling, etc., achieve excellent weld bead shape and appearance, reduce iron water falling, and improve connection strength and forming. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

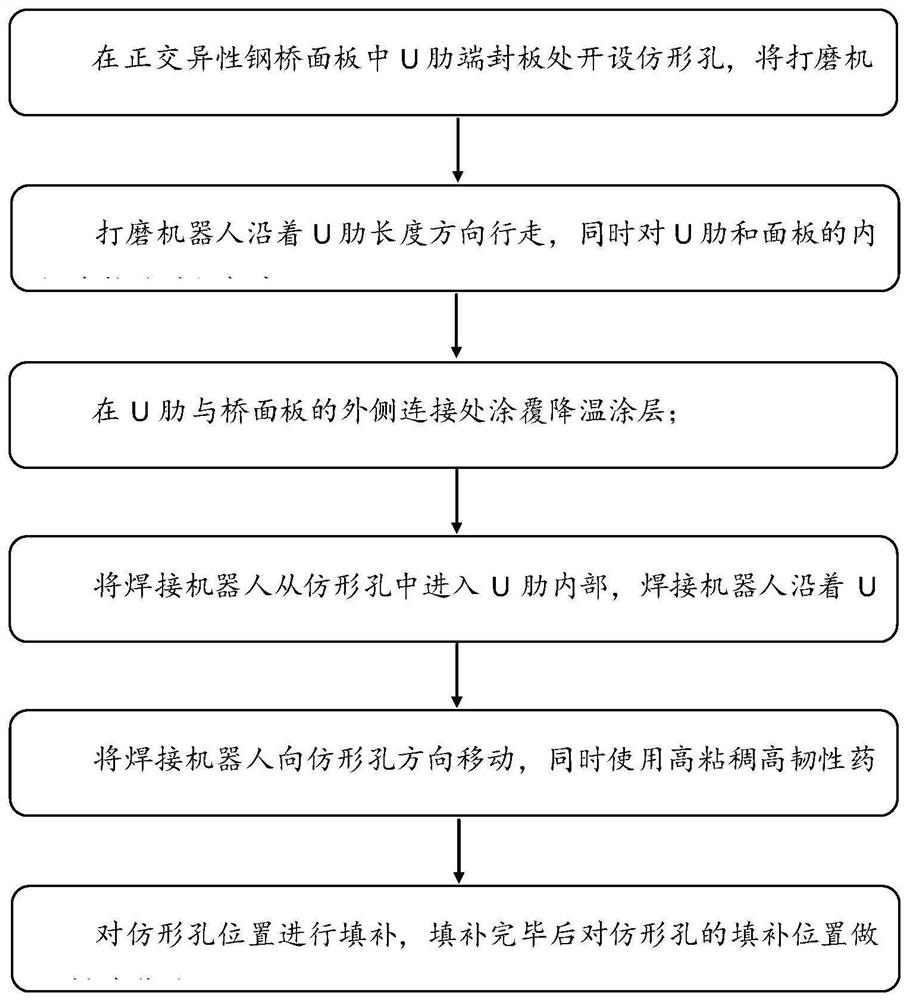

Method used

Image

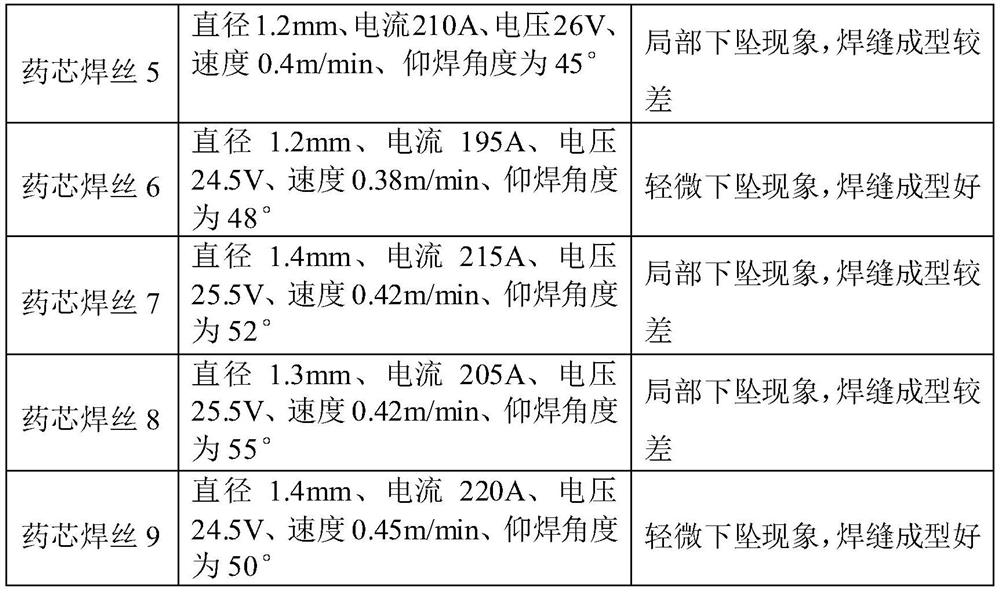

Examples

Embodiment 1

[0036] The preparation method of flux-cored welding wire 1 comprises the following steps:

[0037] 1) Take by weighing 7.0% fluoride, 7.5% barium carbonate, 7.2% zircon sand, 0.5% calcium oxide, 0.6% magnesium oxide, 0.3% potassium oxide, 0.6% barium chloride, 0.3% titanium dioxide, 0.2% silicon dioxide, 5.5% silicon-manganese alloy, 0.8% cobalt powder, 1.8% nickel powder, 3.8% silver powder, 3.0% ferromolybdenum, 1.5% % of ferrovanadium, 2.0% of ferrotitanium, 1.3% of ferroboron, 0.3% of carbon nanotubes, and the balance is iron powder. Among them, the mixture of lithium fluoride and cerium tetrafluoride and lithium fluoride and tetrafluoride The weight ratio of cerium is 1:1; reserve;

[0038] 2) Grinding and mixing fluoride, carbonate, zircon sand, calcium oxide, magnesium oxide, potassium oxide, barium chloride, titanium dioxide, and silicon dioxide, and calcining at a temperature of 680-750°C for 2.5-3 hours , rolled and sieved to make 140-160 mesh mixed powder;

[0039]...

Embodiment 2

[0042] Flux-cored welding wire 2 is basically the same as the flux-cored welding wire 1 prepared in Example 1, except that:

[0043] The raw materials of drug core 2 include 6.8% sodium hexafluoroaluminate, 6.0% manganese carbonate, 6.8% zircon sand, 0.8% calcium oxide, 0.5% magnesium oxide, 0.4% potassium oxide, 0.3% barium chloride, 0.5% titanium dioxide, 0.3% silicon dioxide, 3.0% silicon-manganese alloy, 1.2% cobalt powder, 2.5% nickel powder, 4.2% silver powder, 1.8% ferromolybdenum, 3.0% % ferrovanadium, 2.5% ferro-titanium, 2.8% ferro-boron, 0.5% carbon nanotubes, and the balance is iron powder.

Embodiment 3

[0045] The flux-cored welding wire 3 is basically the same as the flux-cored welding wire 1 prepared in Example 1, except that:

[0046] The raw materials of drug core 3 include 8.5% lithium fluoride, 5.6% barium carbonate, 7.5% zircon sand, 0.4% calcium oxide, 0.2% magnesium oxide, 0.7% potassium oxide, 0.3% Barium chloride, 0.4% titanium dioxide, 0.5% silicon dioxide, 6.2% silicon-manganese alloy, 0.7% cobalt powder, 3.2% nickel powder, 3.5% silver powder, 3.3% ferromolybdenum, 2.0% Ferro-vanadium, 1.5% ferro-titanium, 1.8% ferro-boron, 0.3% carbon nanotubes, and the balance is iron powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com