Polar hot melt adhesive and preparation method thereof

A hot-melt adhesive, polar technology, used in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of limited improvement of hot-melt adhesive performance, lower melting point and softening point, and low bonding strength. , to achieve the effects of excellent cohesive strength, excellent bonding strength, and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

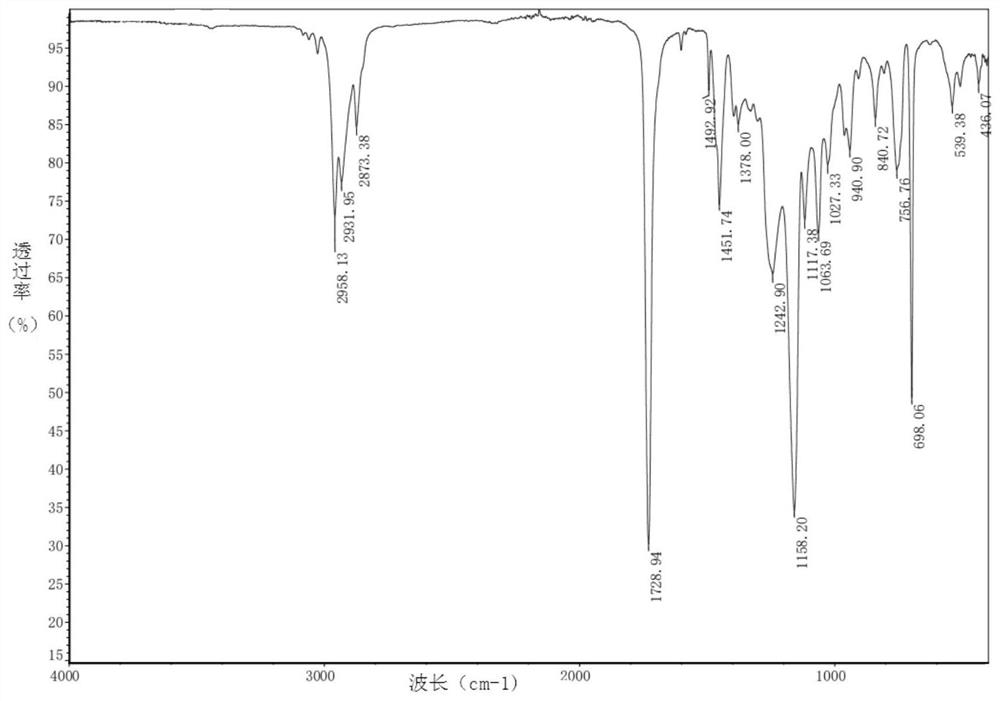

[0076] Embodiment 1 Acrylate block copolymer E-1 preparation

[0077] (1) Stir and dissolve 3 parts by weight of the above-mentioned amphiphilic macromolecular reversible addition fragmentation chain transfer reagent in 150 parts by weight of water, then add 10 parts by weight of styrene monomer, stir and emulsify, pass nitrogen to remove oxygen, and heat up to 60 degrees, add 0.05 parts by weight of water-soluble initiator, and keep warm for 150 minutes.

[0078] (2) 8 parts by weight of rosin glyceride were dissolved in 80 parts by weight of butyl acrylate, and the mixture was slowly added dropwise to the reaction solution in step (1), and the temperature was continued for 300 minutes.

[0079] (3) After step (2) reaction finishes, add the styrene of 5 weight parts, continue to insulate for 200 minutes, obtain latex.

[0080] (4) The obtained latex is added dropwise to 5% hydrochloric acid for demulsification, cleaning, and drying to obtain acrylate block copolymer E-1, who...

Embodiment 2

[0081] Embodiment 2 Preparation of acrylate block copolymer E-2

[0082] (1) Stir and dissolve 2.5 parts by weight of the above-mentioned amphiphilic macromolecular reversible addition fragmentation chain transfer reagent in 150 parts by weight of water, then add 10 parts by weight of styrene monomer, stir and emulsify, pass nitrogen to remove oxygen, and heat up to 60 degrees, add 0.05 parts by weight of water-soluble initiator, and keep warm for 180 minutes.

[0083] (2) 6 parts by weight of rosin glyceride were dissolved in 80 parts by weight of butyl acrylate, and the mixture was slowly added dropwise to the reaction liquid in step (1), and the temperature was continued for 400 minutes.

[0084] (3) After step (2) reaction finishes, add the styrene of 8 weight parts, continue to insulate for 250 minutes, obtain latex.

[0085] (4) The obtained latex is added dropwise to 5% hydrochloric acid for demulsification, cleaning, and drying to obtain acrylate block copolymer E-2, ...

Embodiment 3

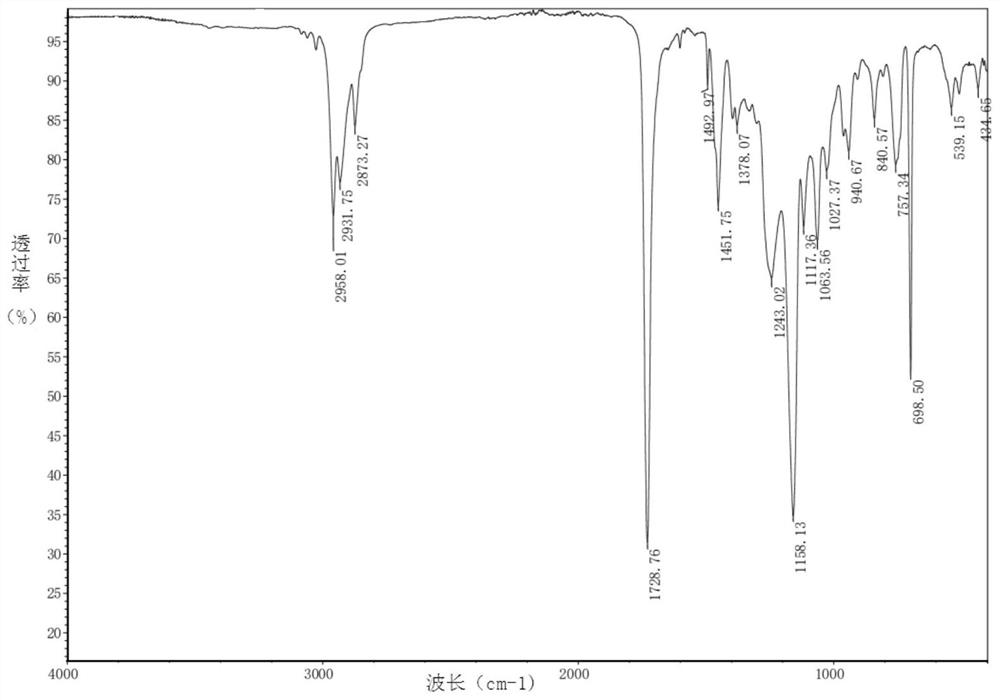

[0086] Embodiment 3 Preparation of acrylate block copolymer E-3

[0087] (1) Stir and dissolve 2.0 parts by weight of the above-mentioned amphiphilic macromolecular reversible addition fragmentation chain transfer reagent in 150 parts by weight of water, then add 10 parts by weight of styrene monomer, stir and emulsify, pass nitrogen to remove oxygen, and heat up to 60 degrees, add 0.05 parts by weight of water-soluble initiator, and keep warm for 200 minutes.

[0088] (2) 5 parts by weight of rosin glyceride were dissolved in 80 parts by weight of butyl acrylate, and the mixture was slowly added dropwise to the reaction solution in step (1), and the temperature was continued for 450 minutes.

[0089] (3) After step (2) reaction finishes, add the styrene of 10 weight parts, continue to insulate for 300 minutes, obtain latex.

[0090] (4) The obtained latex is added dropwise to 5% hydrochloric acid for demulsification, cleaning, and drying to obtain acrylate block copolymer E-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com