Composite coating of metal base material and construction method of composite coating

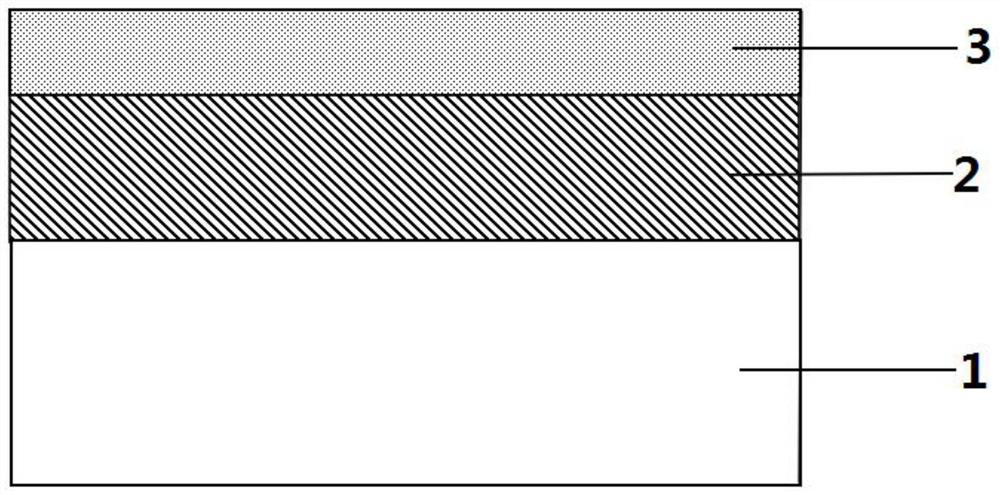

A metal substrate and composite coating technology, applied in metal material coating process, coating, superimposed layer plating and other directions, to achieve the effect of improving anti-corrosion performance, anti-coking performance and convenient material selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

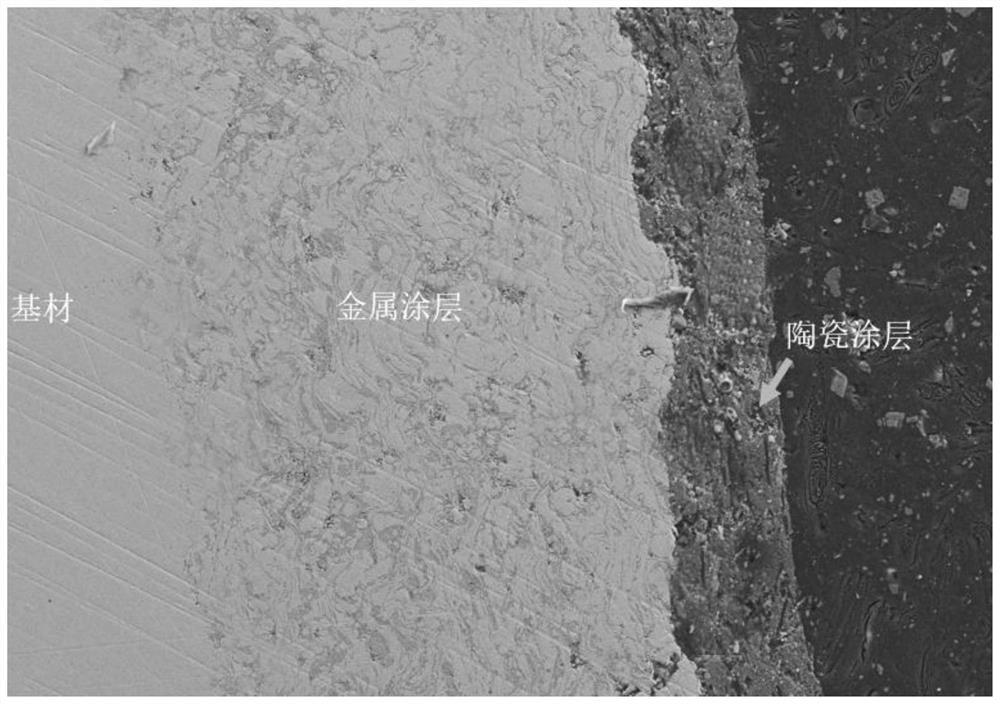

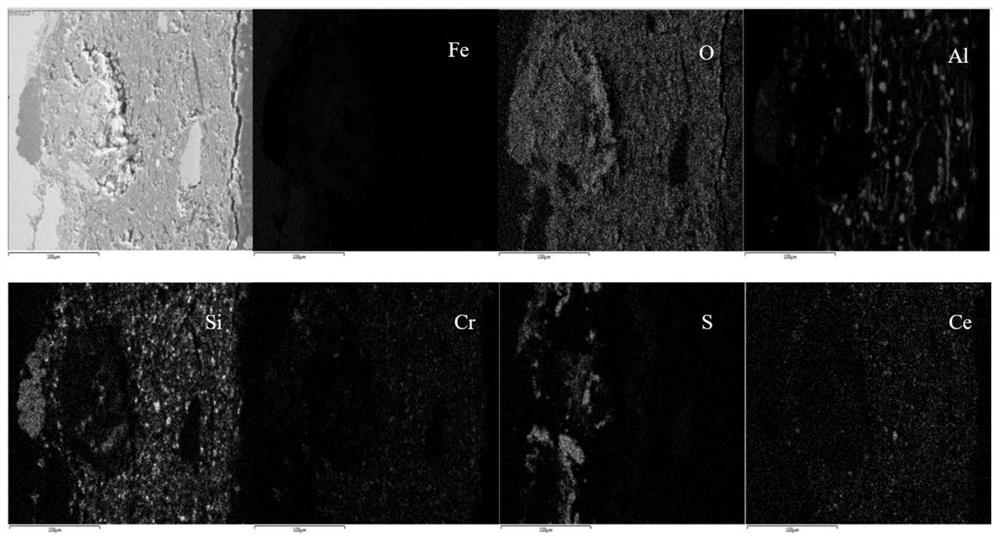

[0086] (1) Select the corroded area of the boiler water wall, sandblast the substrate to make the surface of the substrate reach Sa3.0 level, and blow off the dust particles on the surface of the substrate with compressed air;

[0087] (2) Spray the metal wire with an electric arc spraying machine. The metal wire is composed of metal elements in the following weight percentages: 45% chromium, 4% titanium, and 50% nickel. The diameter of the metal wire is 1.2 mm. Adjust the voltage of the arc spraying machine It is 32V, the spraying current is 160A, the spraying distance is 25cm, and the compressed air flow rate for spraying is 5m 3 / min, the air supply pressure is 0.6Mpa, and the thickness of the sprayed bottom layer is 50μm;

[0088] (3) Spray the surface layer after the bottom layer is cooled to room temperature, weigh the following raw materials and stir evenly, water glass 40%, alumina ceramic powder 20%, cerium oxide 5%, mica 10%, kaolin 5%, silane 1% joint additive, ...

Embodiment 2

[0090] (1) Select the corroded area of the boiler water wall, sandblast the substrate to make the surface of the substrate reach Sa2.5 level, and blow off the dust particles on the surface of the substrate with compressed air;

[0091] (2) Use an arc spraying machine to spray the metal elemental wire. The metal wire is composed of the following metal elements by weight: 45% chromium, 4% titanium, and 50% nickel. The diameter of the metal wire is 3.0㎜. Adjust the arc spraying machine The voltage is 36V, the spraying current is 190A, the spraying distance is 30cm, and the compressed air flow rate for spraying is 5m 3 / min, the air supply pressure is 0.7Mpa, and the thickness of the sprayed bottom layer is 200μm;

[0092] (3) Spray the surface layer after the bottom layer is cooled to room temperature, take the following raw materials by weight and stir evenly, water glass 40%, alumina ceramic powder 25%, zirconia 10%, cerium oxide 5%, silane coupling agent 1% agent, 3% pure a...

Embodiment 3

[0094] (1) Select the corroded area of the boiler water wall, sandblast the substrate to make the surface of the substrate reach Sa3.0 level, and blow off the dust particles on the surface of the substrate with compressed air;

[0095] (2) Spray metal elemental wire with a flame spray gun, and the metal wire is composed of the following metal elements in weight percent: 4% titanium, 25% chromium, 5% aluminum, 2% molybdenum, 1% rare earth, 1% vanadium, nickel 10%, iron 52%, the diameter of the metal wire is 6mm, the oxygen flow rate is adjusted to 100L / min, the acetylene flow rate is 100L / min, the spraying distance is 40cm, and the thickness of the spraying bottom layer is 500μm;

[0096] (3) Spray the surface layer after the bottom layer is cooled to room temperature, weigh the following raw materials and stir evenly, phosphate binder 40%, corundum ceramic powder 20%, aluminum powder 8%, cerium oxide 5%, silane coupling Additive agent 1%, silicon nitride 8%, chrome green 12%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com