Preparation method of high-pressure-resistant, high-temperature-resistant and water-resistant water pump flexible joint rubber

A technology of water resistance and high pressure resistance, which is applied in the field of preparation of flexible joint rubber for high pressure and high temperature water resistance water pumps. It can solve the problems of high temperature resistance and achieve good heat resistance and increase flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

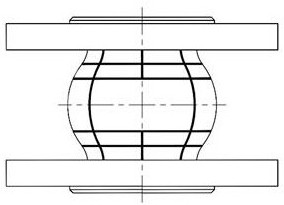

Image

Examples

Embodiment 1

[0025]The first step, weighing the following raw materials in parts by weight: 0.6 parts of rare earth composite stabilizer, 10 parts of mercaptan end-group liquid nitrile rubber, 78 parts of partial chloride resin, 15 parts of modified liquid polysulfide rubber, filler pomegranate 14 parts of stone powder, 0.7 part of glyceryl distearate, 41 parts of activator trioctyl trimellitate, 0.8 part of crosslinking agent manganese dioxide; the second step, preparation of slurry: stabilizer, partial chloride resin and Active light moissanite powder is added to the mixer, and the mixer is stirred at a speed of 300 rpm to 45°C, and then the prepared modified liquid polysulfide rubber and mercaptan-terminated liquid nitrile rubber are added to the mixer at a speed of 500 rpm , when the modified liquid polysulfide rubber and mercaptan-terminated liquid nitrile rubber are uniformly absorbed, then add an activator and a cross-linking agent and stir for 15 minutes to obtain a mixed slurry; th...

Embodiment 2

[0028] The first step, weigh the following raw materials in parts by weight: 0.3 parts of calcium-zinc composite stabilizer, 8 parts of mercaptan end-group liquid nitrile rubber, 76 parts of partial chloride resin, 13 parts of modified liquid polysulfide rubber, moissanite 12 parts of powder filler, 0.5 part of glyceryl distearate, 37 parts of activator dioctyl terephthalate, 0.5 part of calcium peroxide crosslinking agent; the second step, preparation of slurry: mix stabilizer, partial chloride resin Add active light moissanite powder into the mixer, stir the mixer at a speed of 200 rpm to 45°C, and then add the prepared modified liquid polysulfide rubber and mercaptan-terminated liquid nitrile to the mixer at a speed of 400 rpm Rubber, when the modified liquid polysulfide rubber and the mercaptan end-group liquid nitrile rubber are evenly absorbed, then add an activator and a crosslinking agent and stir for 10 minutes to obtain a mixed slurry; the third step, rotating Moldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com