High-temperature-resistant formaldehyde-removing polyethylene and preparation method thereof

A technology of high temperature resistant and polyethylene, applied in the field of high temperature resistant formaldehyde removal polyethylene and its preparation, can solve the problems of reducing the electrical properties of cross-linked polyethylene, improve mechanical properties and heat resistance, wide application, good removal The effect of formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

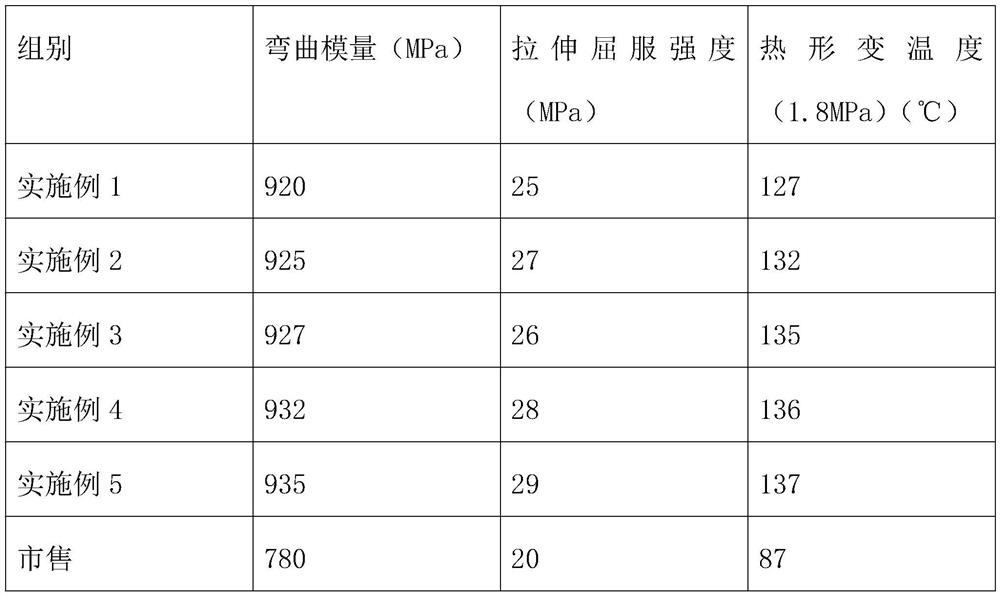

Examples

preparation example 1

[0030] Titanium dioxide hollow spheres of preparation example 1 loaded catalyst

[0031] Prepared by:

[0032] S1. Dissolve 15g of tetrabutyl titanate in 100mL of dichloromethane, add 1g of titanate coupling agent TMC-311, stir and mix evenly to obtain an oil phase;

[0033] S2. Dissolving 10 g of surfactant sodium stearate and 1 g of porogen polyethylene glycol octylphenyl ether in 100 mL of water to obtain an aqueous phase;

[0034] S3. After mixing 10 g of the oil phase and 30 g of the water phase, homogenize at 10,000 r / min for 2 minutes to obtain an emulsion, react for 1 hour to obtain a porous titanium dioxide hollow sphere emulsion, filter and dry to obtain a dry powder of porous titanium dioxide hollow spheres;

[0035] S4. Dissolve 2g of palladium-carbon catalyst in 50mL of dichloromethane, add 100g of dry powder of porous titanium dioxide hollow spheres, soak for 3h, suction filter, and dry to obtain catalyst-loaded titanium dioxide hollow spheres.

preparation example 2

[0036] Titanium dioxide hollow spheres of preparation example 2 loaded catalyst

[0037] Prepared by:

[0038] S1. Dissolve 15g of tetrabutyl titanate in 100mL of ethyl acetate, add 2g of titanate coupling agent TMC-2, stir and mix evenly to obtain an oil phase;

[0039] S2. Dissolving 10 g of surfactant sodium dodecyl sulfonate and 5 g of porogen polyethylene glycol octylphenyl ether in 100 mL of water to obtain an aqueous phase;

[0040] S3. After mixing 10 g of the oil phase and 50 g of the water phase, homogenize at 10,000 r / min for 2 minutes to obtain an emulsion, react for 3 hours to obtain a porous titanium dioxide hollow sphere emulsion, filter and dry to obtain a dry powder of porous titanium dioxide hollow spheres;

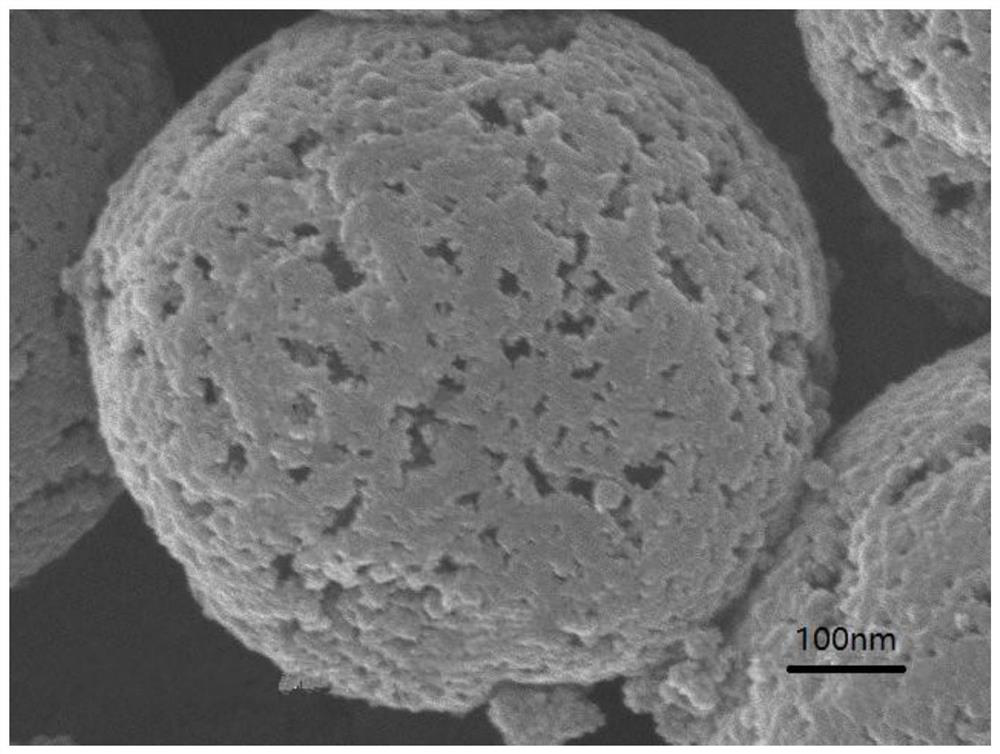

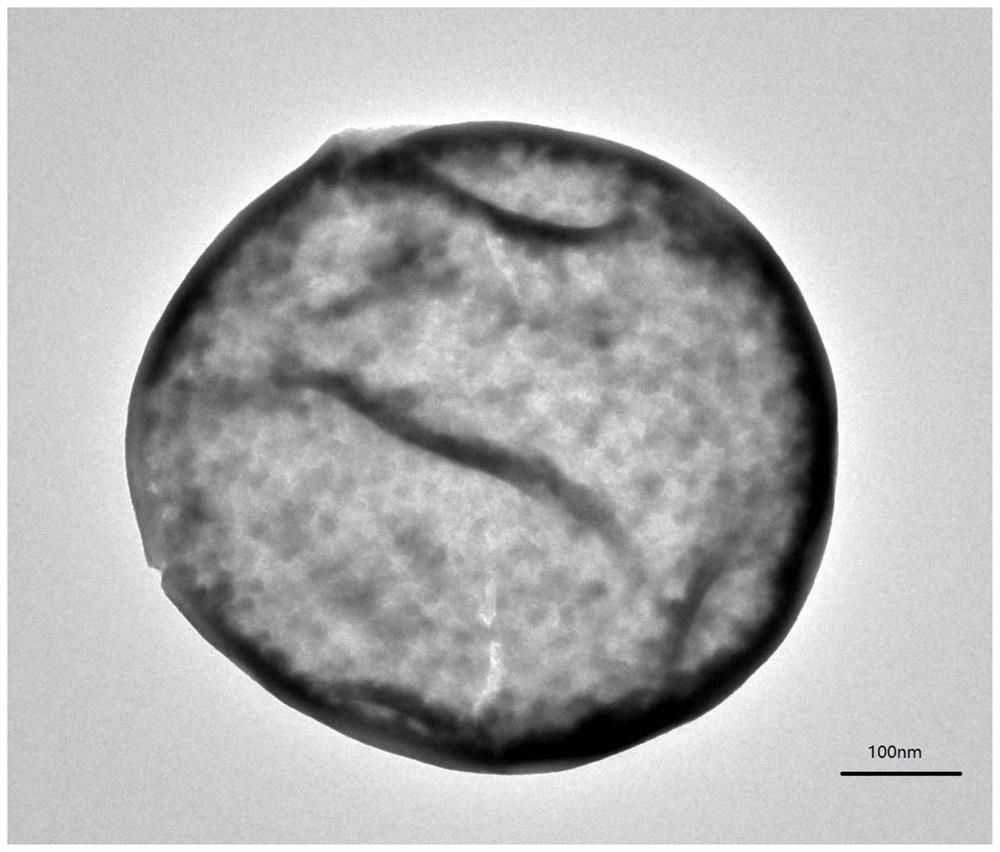

[0041] S4. Dissolve 5g palladium carbon catalyst in 50mL ethyl acetate, add the dry powder of 100g porous titanium dioxide hollow spheres, soak for 5h, suction filter, dry, obtain the titanium dioxide hollow spheres of loaded catalyst, its SEM figure se...

Embodiment 1

[0043] Composition of raw materials (parts by weight): 10 parts of titanium dioxide hollow spheres loaded with catalyst, 100 parts of ethylene, 200 parts of tetrahydrofuran, 1 part of stabilizer zinc stearate, 1 part of plasticizer di-sec-octyl phthalate, toughener 0.5 parts of polyimide and 0.1-0.5 parts of antioxidant p-phenylenediamine.

[0044] Include the following steps:

[0045] S1. Pass ethylene into tetrahydrofuran, after absorbing saturation, add titanium dioxide hollow spheres loaded with catalyst, react at 50°C for 2 hours, add hydrochloric acid / ethanol mixed solution (HCl content is 20-35wt%) to terminate the reaction, and the obtained polymer After washing with tetrahydrofuran, drying to obtain a polyethylene resin containing titanium dioxide hollow spheres;

[0046] S2. Add polyethylene resin containing titanium dioxide hollow spheres, stabilizer zinc stearate, plasticizer dioctyl phthalate, toughening agent polyimide and antioxidant p-phenylenediamine to the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com