Zwitterionic polymer and heparin composite coating as well as preparation method and application thereof

A zwitterion, composite coating technology, applied in coatings, drug delivery, pharmaceutical formulations, etc., can solve problems such as reducing the hydrophobicity of membrane pores and increasing the risk of blood leakage through the micropores of the membrane wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

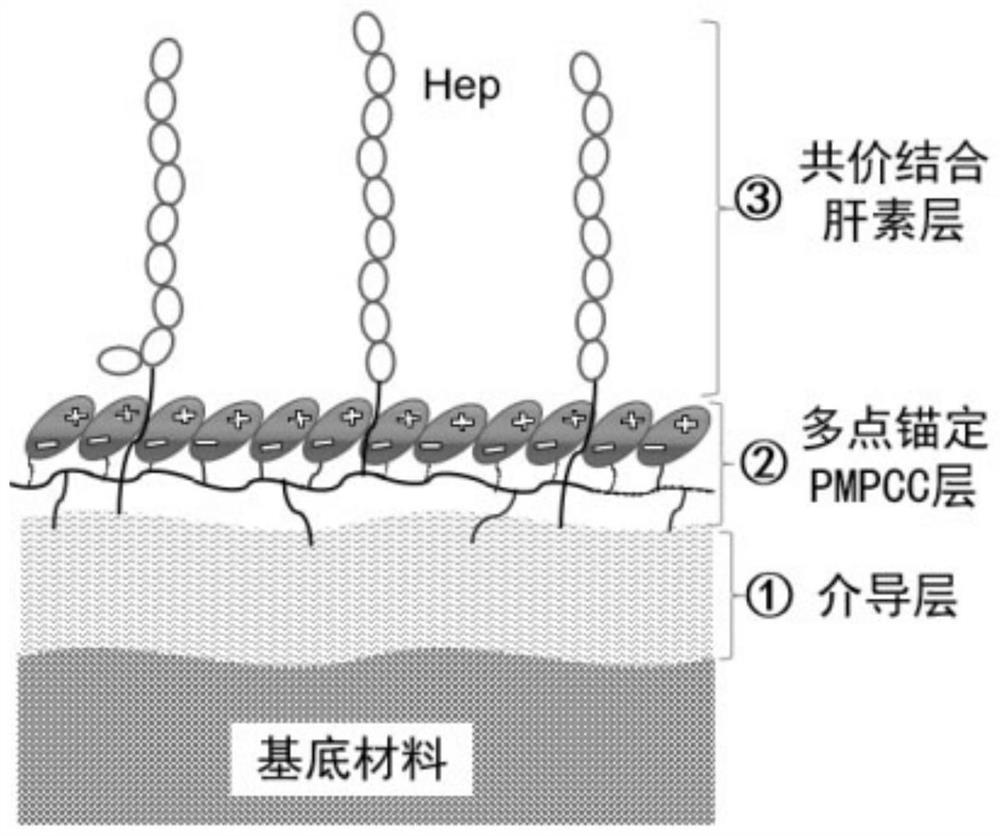

[0046] The preparation method of the zwitterionic polymer and heparin composite coating of the present invention comprises the following steps:

[0047] Step 1: Provide a mediator layer, mix the biomimetic universal adhesive material A and the crosslinking agent B according to the mass ratio of A:B=10:1~3:2 to prepare an A+B aqueous solution, and immerse the material to be modified in the aqueous solution , get the mediation layer.

[0048] The main component of the biomimetic universal adhesive material A in the mediation layer is dopamine hydrochloride or dopa hydrochloride containing catechol groups, which are biomimetic adhesion molecules that are easily oxidized and polymerized. Biomimetic adhesion molecules will be oxidatively polymerized by dissolved oxygen or added oxidants in aqueous solution, and automatically form a coating that adheres to the surface of the material and can be modified again. In the aqueous solution, it is difficult for the adhesion molecules to e...

Embodiment 1

[0063] Step 1, dissolve dopamine hydrochloride and polyethyleneimine (PEI) in a mixed solvent of absolute ethanol: pH8.5 Tris-HCl buffer solution = 1:1 (volume ratio of 10:1) according to the mass ratio , prepared as a solution containing dopamine hydrochloride 2mg / mL, PEI 0.2mg / mL, immersed in different material sheets in Table 1 and reacting at 90rpm for 6h based on a 30°C water-bath shaker. Take it out, rinse it with deionized water, dry it with cold air, and measure its contact angle. The significant changes in the water contact angle of the surface before and after coating in Table 1 indicate that the mediation layer was successfully constructed.

[0064] Table 1. Variations of water contact angles on the surface of substrates of different materials before and after coating with a dielectric layer.

[0065] material type Water contact angle before coating (°) Water contact angle after coating (°) glass sheet 30.3±2.0 33.5±1.3 polycarbonate sheet...

Embodiment 2

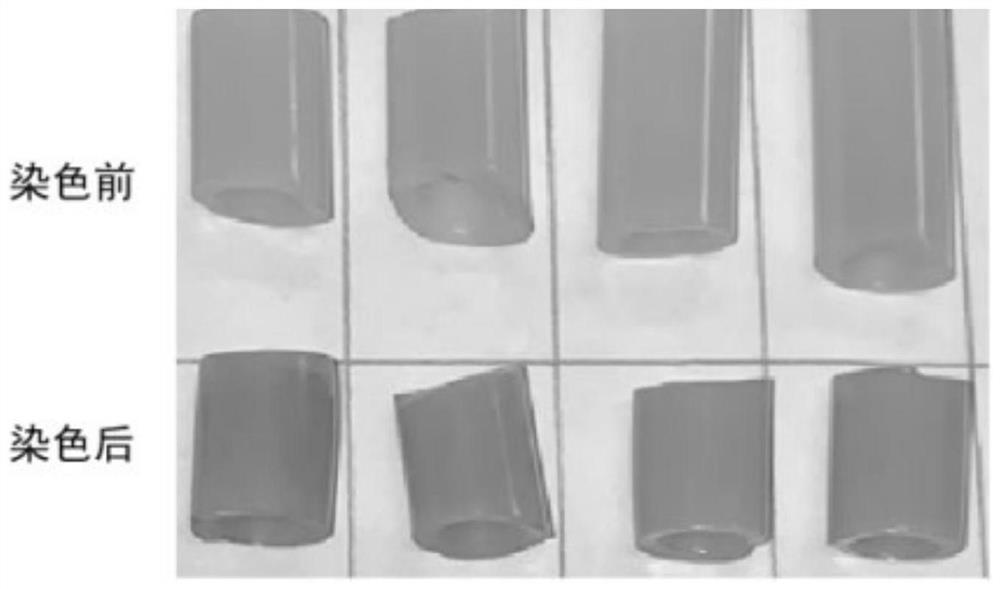

[0069]Step 1, mix and prepare the bionic universal adhesive material A and crosslinking agent B aqueous solution shown in Table 2 according to the mass ratio of 10:1 to 3:2, soak and wash the PVC catheter with absolute ethanol, and then immerse it in the water solution shown in Table 2 respectively. In the solution, react at 30°C for 4h to build a mediator coating. After the catheter was taken out and rinsed with a large amount of deionized water, the water contact angle was measured after drying with a hair dryer at room temperature. Compared with the water contact angle of the PVC pipe department before modification, the significantly reduced water contact angle indicated that PVC / PDA, PVC / PDA-PEI, PVC / PDA-PLys, PVC / PDA-APTMS, PVC / PDopa-PEI and PVC / PDA PDopa-PLys-mediated coating construction was successful.

[0070] Table 2. The water contact angle and solution composition of the mediation coating constructed by dip coating on the surface of PVC catheter.

[0071]

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viewing angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com