Feed additive for preventing early death of prawns and its preparation method and application

A feed additive and shrimp technology, which is applied in the field of feed additives for preventing the early death of shrimp and its preparation, can solve the problems of long duration of feed, influence on feed efficacy, lack of effective components, etc., to ensure stable properties and effective absorption, and prevent early Death Syndrome, Guaranteed Effective Absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

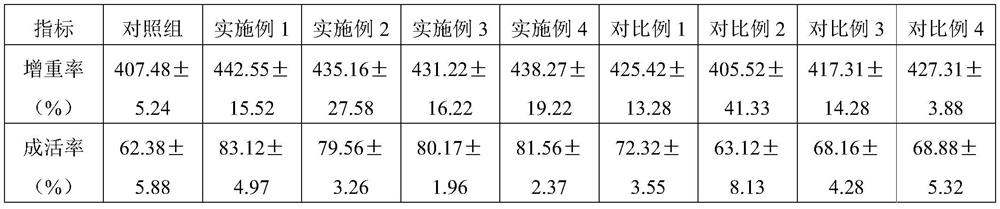

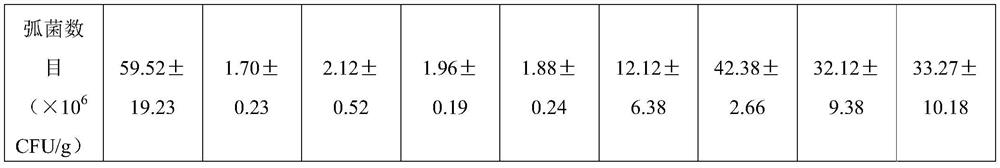

Examples

Embodiment 1

[0036] Homogenizing the Haematococcus pluvialis liquid with a mass fraction of 5.5% under a pressure of 30 MPa for 3 to 5 times to obtain the broken-walled Haematococcus pluvialls liquid and the Haematococcus pluvialls liquid;

[0037] After mixing 15kg polyvinyl acetate phthalate, 3kg triethyl citrate, and 2kg magnesium stearate, add 80 kg of water, and after mixing, pass through 100 meshes to obtain coating suspension A;

[0038] The obtained coating suspension A and the broken-walled Haematococcus pluvialis liquid were sprayed and mixed for 5 minutes according to the mass ratio of 2:1.5, homogenized for 3 times under a pressure of 30 MPa, and spray drying was used during spray mixing and stirring. 0.5mm nozzle, the inlet temperature is 180°C, and the coated broken Haematococcus pluvialis microcapsule powder is obtained;

[0039]Put 30kg of silicon dioxide in the reaction kettle, turn on the stirring paddle, put 10kg of tributyrin in the liquid supply tank of the spraying de...

Embodiment 2

[0043] Homogenizing the algae liquid of Haematococcus pluvialis with a mass fraction of 5.5% under a pressure of 30 MPa for 3 to 5 times to obtain the algae liquid of Haematococcus pluvialis with broken walls;

[0044] After mixing 12kg polyvinyl acetate phthalate, 2kg triethyl citrate, and 1.5kg magnesium stearate, add 84.5kg of water, mix well and pass through 100 meshes to obtain coating suspension A;

[0045] The obtained coating suspension A and the broken-walled Haematococcus pluvialis liquid were sprayed and mixed for 5 minutes according to the mass ratio of 2:1, homogenized for 3 times under 30MPa pressure, and spray drying was used during spray mixing and stirring. 0.5mm nozzle, the inlet temperature is 180°C, and the coated broken Haematococcus pluvialis microcapsule powder is obtained;

[0046] Put 35kg of silicon dioxide in the reaction kettle, turn on the stirring paddle, put 10kg of tributyrin in the liquid supply tank of the spraying device, continue stirring fo...

Embodiment 3

[0050] Homogenizing the Haematococcus pluvialis liquid with a mass fraction of 5.5% under a pressure of 30 MPa for 3 to 5 times to obtain the broken-walled Haematococcus pluvialls liquid and the Haematococcus pluvialls liquid;

[0051] 13kg of polyvinyl acetate phthalate, 2.5kg of triethyl citrate, and 2kg of magnesium stearate were mixed uniformly and then 82.5kg of water was added to obtain coating suspension A through 100 meshes after uniform mixing;

[0052] The obtained coating suspension A and the broken-walled Haematococcus pluvialis liquid were sprayed and mixed for 5 minutes according to the mass ratio of 2:1.25, homogenized for 3 times under 30MPa pressure, and spray drying was used during spray mixing and stirring. 0.5mm nozzle, the inlet temperature is 180°C, and the coated broken Haematococcus pluvialis microcapsule powder is obtained;

[0053] Put 30kg of silicon dioxide in the reaction kettle, turn on the stirring paddle, put 10kg of tributyrin in the liquid sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com