Treatment method of ammonia-containing waste gas

A treatment method and technology for waste gas, which are applied in separation methods, anaerobic digestion treatment, water treatment parameter control, etc., can solve the problems of secondary pollutant nitrogen-containing wastewater, poor ammonia removal effect, and large amount of treatment agent. Achieve high removal efficiency, no secondary pollution, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for treating ammonia-containing waste gas, said method comprising the following steps:

[0037] (1) Prepare trace element culture solution, including the following components: 9g / L ferric sulfate, 5g / L disodium edetate, 0.054g / L potassium dihydrogen phosphate, 1g / L sodium bicarbonate, 0.7g / L L calcium chloride, 0.5g / L magnesium sulfate, 0.7g / L potassium chloride, 0.5g / L sodium chloride, 0.24mg / L cobalt chloride, 0.014mg / L boric acid, 0.22mg / L sodium molybdate, 0.43mg / L zinc sulfate, 0.25mg / L copper sulfate, 0.99mg / L manganese chloride and 0.19mg / L nickel chloride.

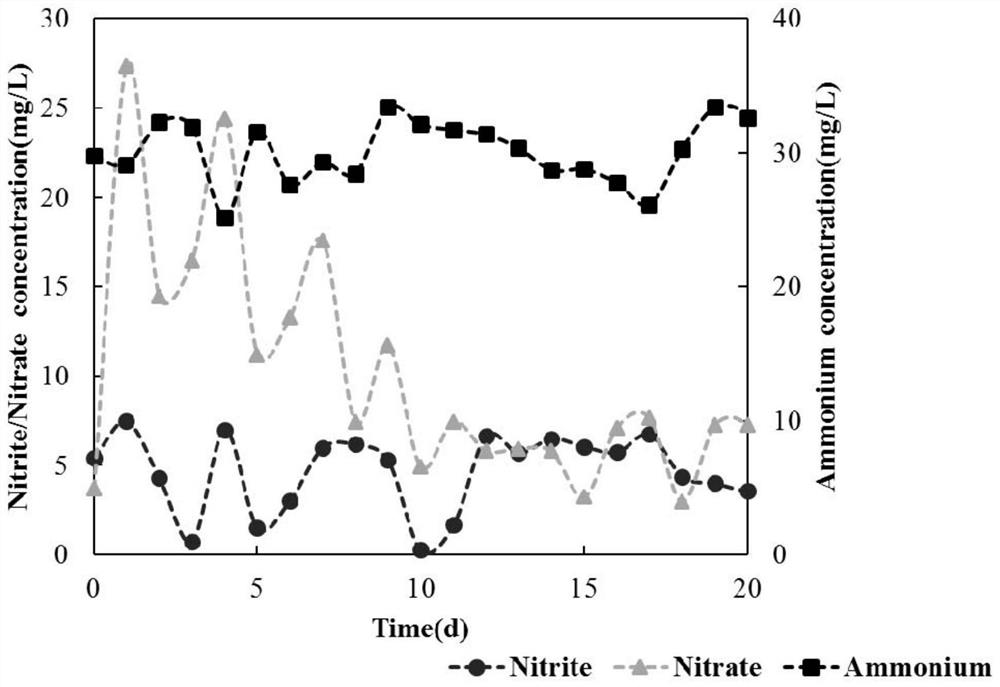

[0038] (2) Mix the activated sludge with a relative abundance of 44.9% of the anammox bacteria Candidatus Kueneia and the trace element culture solution, adjust the pH value to 7.6, and make the anammox bacteria ferment and grow at a temperature of 35°C for 3 1 day, the inoculation medium was obtained, and at this time, the relative abundance of anammox bacteria was 17.3%; then waste gas containing...

Embodiment 2

[0040] A method for treating ammonia-containing waste gas, said method comprising the following steps:

[0041] (1) Prepare trace element culture solution, including the following components: 9g / L ferric sulfate, 5g / L disodium edetate, 0.054g / L potassium dihydrogen phosphate, 1g / L sodium bicarbonate, 0.7g / L L calcium chloride, 0.5g / L magnesium sulfate, 0.7g / L potassium chloride, 0.5g / L sodium chloride, 0.24mg / L cobalt chloride, 0.014mg / L boric acid, 0.22mg / L sodium molybdate, 0.43mg / L zinc sulfate, 0.25mg / L copper sulfate, 0.99mg / L manganese chloride and 0.19mg / L nickel chloride.

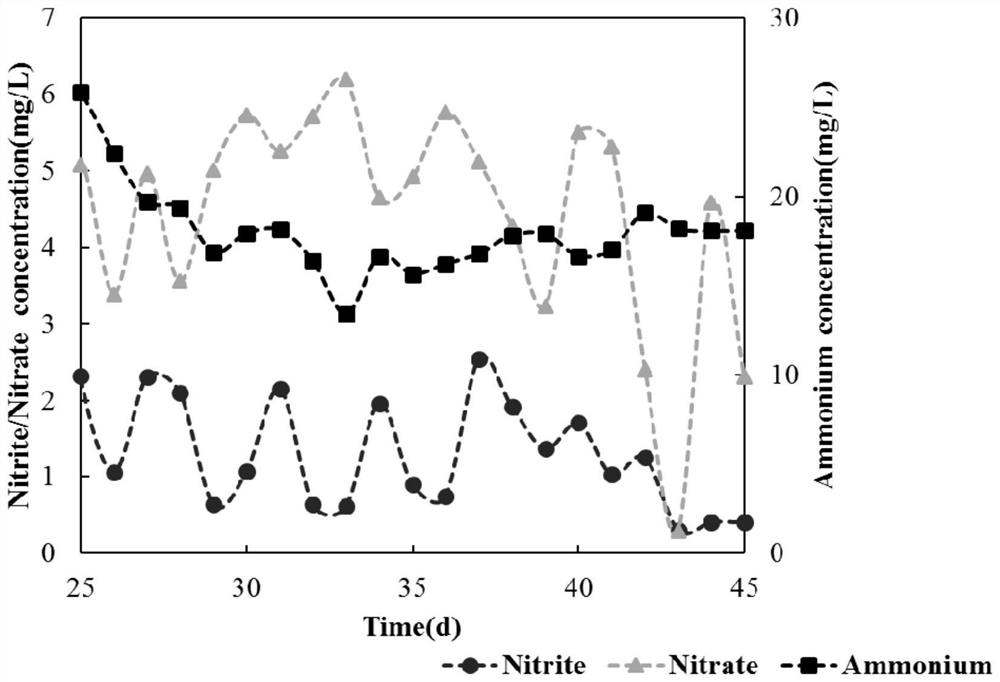

[0042] (2) Mix the activated sludge with a relative abundance of 44.9% of the anammox bacteria Candidatus Kueneia and the trace element culture solution, adjust the pH value to 7.6, and make the anammox bacteria ferment and grow at a temperature of 35°C for 3 day, the inoculation medium was obtained, and at this time, the relative abundance of anammox bacteria was 17.3%; then the waste gas containing...

Embodiment 3

[0044] A method for treating ammonia-containing waste gas, said method comprising the following steps:

[0045] (1) Prepare trace element culture solution, including the following components: 9g / L ferric sulfate, 5g / L disodium edetate, 0.054g / L potassium dihydrogen phosphate, 1g / L sodium bicarbonate, 0.7g / L L calcium chloride, 0.5g / L magnesium sulfate, 0.7g / L potassium chloride, 0.5g / L sodium chloride, 0.24mg / L cobalt chloride, 0.014mg / L boric acid, 0.22mg / L sodium molybdate, 0.43mg / L zinc sulfate, 0.25mg / L copper sulfate, 0.99mg / L manganese chloride and 0.19mg / L nickel chloride.

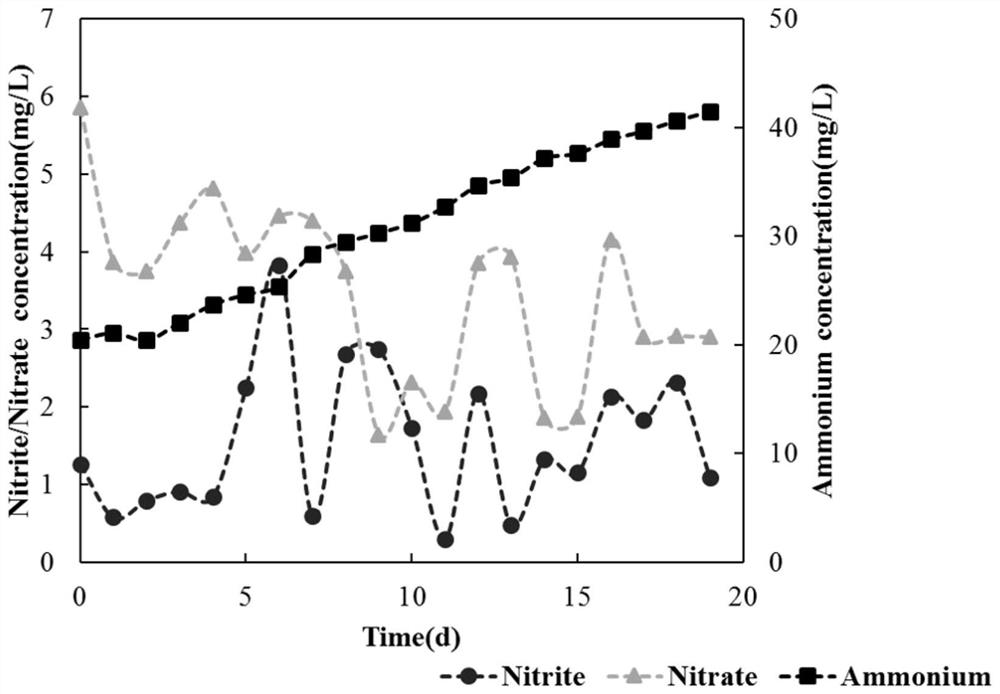

[0046] (2) Mix the activated sludge with a relative abundance of 44.9% of the anammox bacteria Candidatus Kueneia and the trace element culture solution, adjust the pH value to 7.6, and make the anammox bacteria ferment and grow at a temperature of 35°C for 3 day, the inoculation medium was obtained, and at this time, the relative abundance of anammox bacteria was 17.3%; then the waste gas containi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com