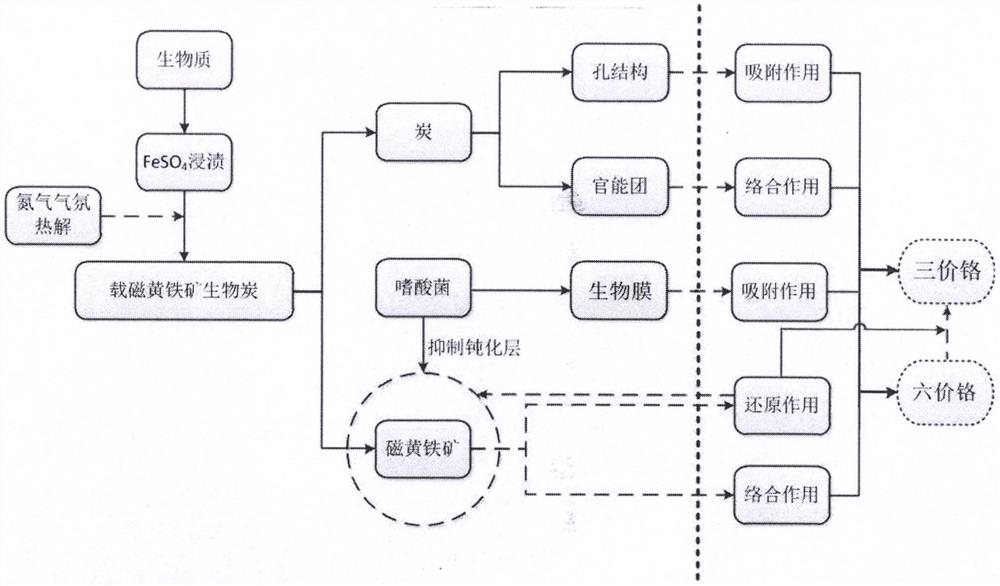

Method for treating hexavalent chromium wastewater based on pyrrhotite biochar loaded acidophilic bacteria biological membrane

A technology of pyrrhotite and acidophilic bacteria, which is applied in the field of pollutant biological treatment, can solve the problems of high cost of reducing agent, reducing the utilization rate of reducing agent, and low treatment efficiency, so as to avoid secondary pollution and increase the reduction rate , filter thoroughly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

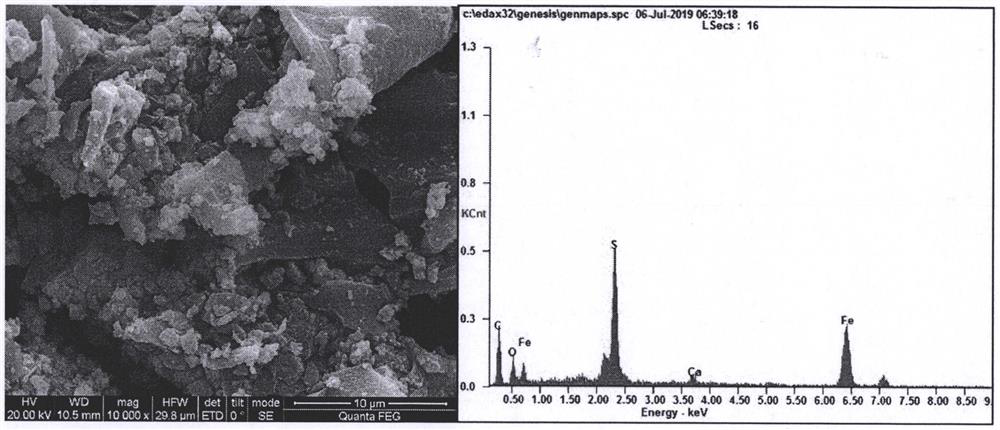

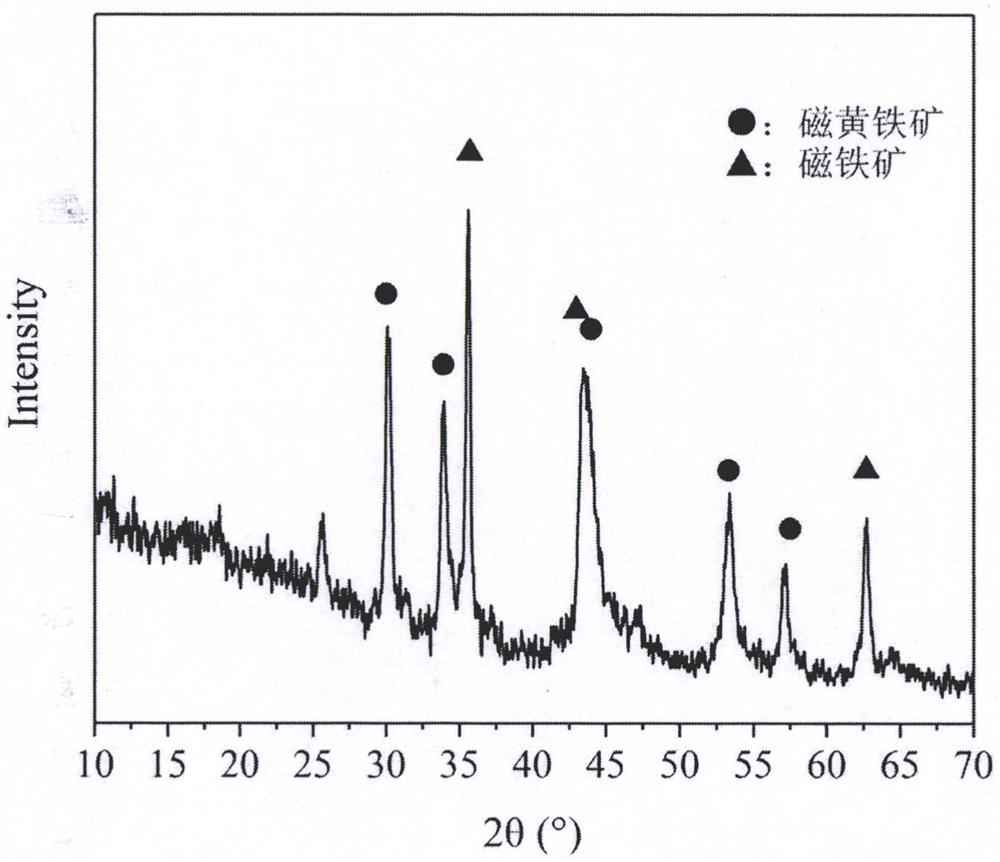

example 1

[0022] The simulated wastewater with a concentration of 300mg / L was treated at a temperature of 25°C and a pH of 5.5. The waste sawdust from a furniture factory was crushed and passed through a 20-mesh sieve to obtain sawdust powder; after mixing ferrous sulfate and sawdust powder according to the ratio of 0.8:1 in mass ratio, they were made into a 15% (w / v) suspension, fully After stirring, dry at 105°C, place in a tube furnace, and pyrolyze at 600°C for 1 hour under nitrogen atmosphere to obtain pyrrhotite-loaded biochar; inoculate ferrous sulfur oxide into 9K medium Bacillus, cultivated to the logarithmic phase at 28°C; add the loaded orpiment iron biochar into the medium at a ratio of 10% (w / v), shake it at 120 rpm for 0.5h, and filter to obtain the loaded Biochar of acid bacteria: Add the biochar loaded with acidophilic bacteria into the hexavalent chromium wastewater at a ratio of 100g / L, and simultaneously use an aeration device for air aeration to control the dissolved...

example 2

[0024] The electroplating wastewater containing hexavalent chromium in an electroplating factory was treated. The concentration of hexavalent chromium in the wastewater at room temperature was 189.7mg / L, and the pH was 2.5. The straw is pulverized and passed through a 20-mesh sieve to obtain the straw powder; after mixing the ferrous sulfate and the straw powder according to the ratio of 1:1 by mass, they are made into a 30% (w / v) suspension, and after fully stirring, the Dry at ℃, place in a tube furnace, and pyrolyze at 550℃ for 2 hours under nitrogen atmosphere to obtain pyrrhotite-loaded biochar; Cultivate to the logarithmic phase under conditions; add orpiment iron-loaded biochar into the medium at a ratio of 10% (w / v), shake at 180 rpm for 0.5h, and filter to obtain biochar loaded with acidophilus bacteria ; The biochar loaded with acidophilus is added to the hexavalent chromium wastewater in a ratio of 50g / L, and an aeration device is used for air aeration at the same t...

example 3

[0026] The electroplating wastewater containing hexavalent chromium from a chromium salt factory was treated. The concentration of hexavalent chromium in the wastewater at room temperature was 156.8 mg / L, and the pH was 3. Pulverize the rice husk and pass through a 40-mesh sieve to obtain rice husk powder; mix ferrous sulfate and rice husk powder according to the ratio of 0.8:1 by mass, make a 20% (w / v) suspension, and stir thoroughly , dried at 65°C, placed in a tube furnace, and pyrolyzed at 650°C for 3 hours in a nitrogen atmosphere to obtain pyrrhotite-loaded biochar; inoculate Thiobacillus ferrooxidans and Sulfobacillus, cultivated at 35°C for 24h to the logarithmic phase; add orpiment iron-loaded biochar into the medium at a ratio of 10% (w / v), shake at 120 rpm for 1h, and obtain the loaded Biochar of acidophilus: add the biochar loaded with acidophilus into the hexavalent chromium wastewater at a ratio of 45g / L, and use an aeration device to aerate with oxygen to contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com