Doped high-pressure ferronickel separation method for pickle liquor

A separation method and acid leaching liquid technology, applied in the field of hydrometallurgy, can solve the problems of high sulfur content, lower iron grade of iron removal slag, and waste slag accumulation, so as to improve the stirring efficiency, reduce the cost of nickel extraction, and increase the contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

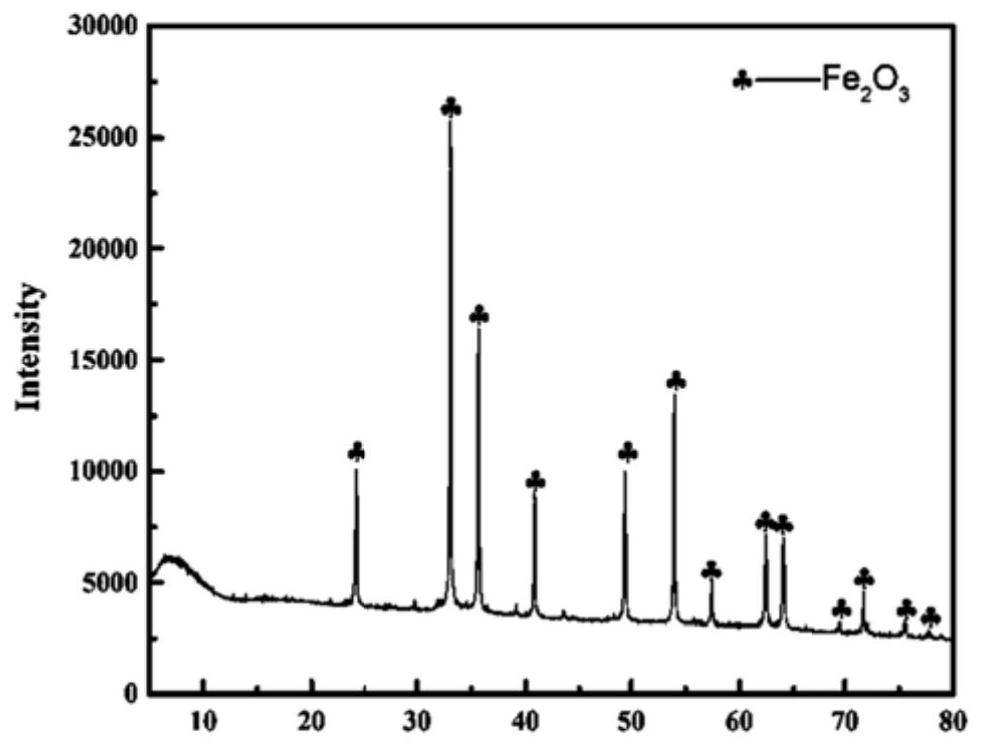

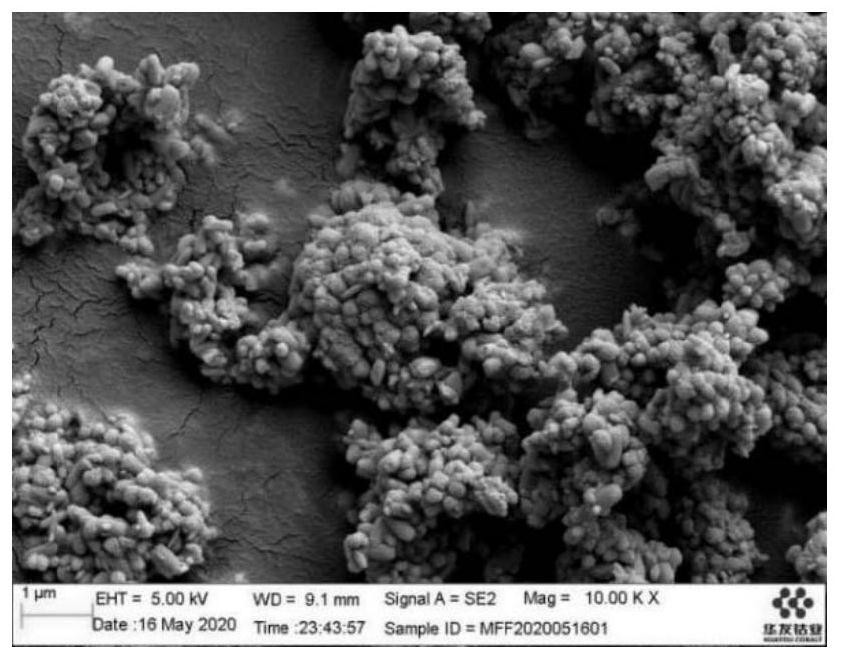

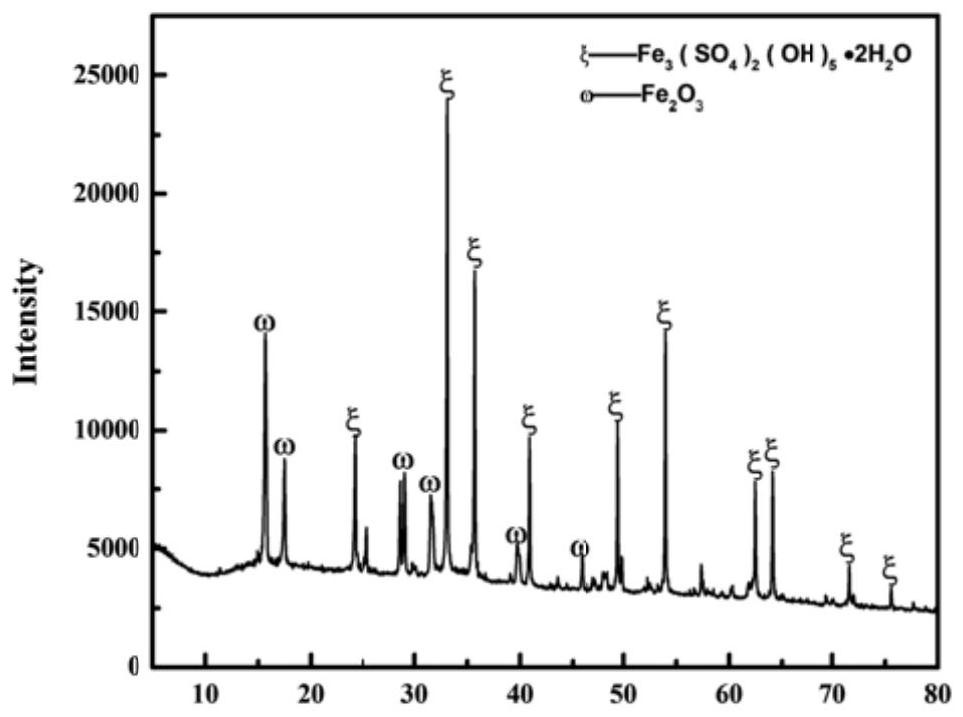

Embodiment 1

[0035] After a crude nickel hydroxide material is leached with sulfuric acid, a leaching solution containing 63g / L of nickel and 21g / L of iron is obtained, and Ni(OH) is added at a concentration of 35g / L 2 Additive, add-on is 51.3g / L, obtains the liquid before nickel-iron separation that pH is 4.27. Put it into the reaction kettle continuously, react at 170°C and 0.4MPa oxygen partial pressure environment in the 2nd and 3rd stages, control the liquid feeding speed, make the solution flow and react in the high-pressure equipment for about 5 hours, after the reaction, the nickel-iron is separated The rear liquid is depressurized by the pressure relief device, and the generated steam heat resource is returned to the front end to maintain the temperature of the liquid before nickel-iron separation. The nickel-iron separated liquid after pressure relief enters the thickener at 83°C. After polyacrylamide flocculation and sedimentation, the supernatant liquid is separated from the li...

Embodiment 2

[0040] A certain acid leaching solution contains 73g / L nickel and 26g / L iron, and NiCO is added at a concentration of 40g / L. 3 Additives, the addition amount is 94.6 g / L, and the nickel-iron separation solution with a pH of 4.06 is obtained. Put it into the reaction kettle continuously, and react at 180°C and 0.4MPa oxygen partial pressure environment in the 2nd and 3rd stages, control the liquid feeding speed, and make the solution flow and react in the high-pressure equipment for about 4 hours. After the reaction, the nickel-iron is separated The rear liquid is depressurized by the pressure relief device, and the generated steam heat resource is returned to the front end to maintain the temperature of the liquid before nickel-iron separation. The nickel-iron separated liquid after pressure relief enters the thickener at 88°C. After polyacrylamide flocculation and sedimentation, the supernatant liquid is separated from the liquid by pressure filtration, and the bottom flow is...

Embodiment 3

[0042] A certain acid leaching solution contains 61g / L nickel and 19g / L iron, and NiO additive is added at a concentration of 40g / L in an amount of 19.7g / L to obtain a pre-nickel-iron separation solution with a pH of 3.93. Put it into the reaction kettle continuously, react at 190°C and 0.3MPa oxygen partial pressure environment in the 2nd and 3rd stages, control the liquid feeding speed, make the solution flow and react in the high-pressure equipment for about 4 hours, after the reaction, the nickel-iron is separated The rear liquid is depressurized by the pressure relief device, and the generated steam heat resource is returned to the front end to maintain the temperature of the liquid before nickel-iron separation. The nickel-iron separated liquid after pressure relief enters the thickener at 89°C. After polyacrylamide flocculation and sedimentation, the supernatant liquid is separated from the liquid and solid by pressure filtration, and the bottom flow is separated from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com