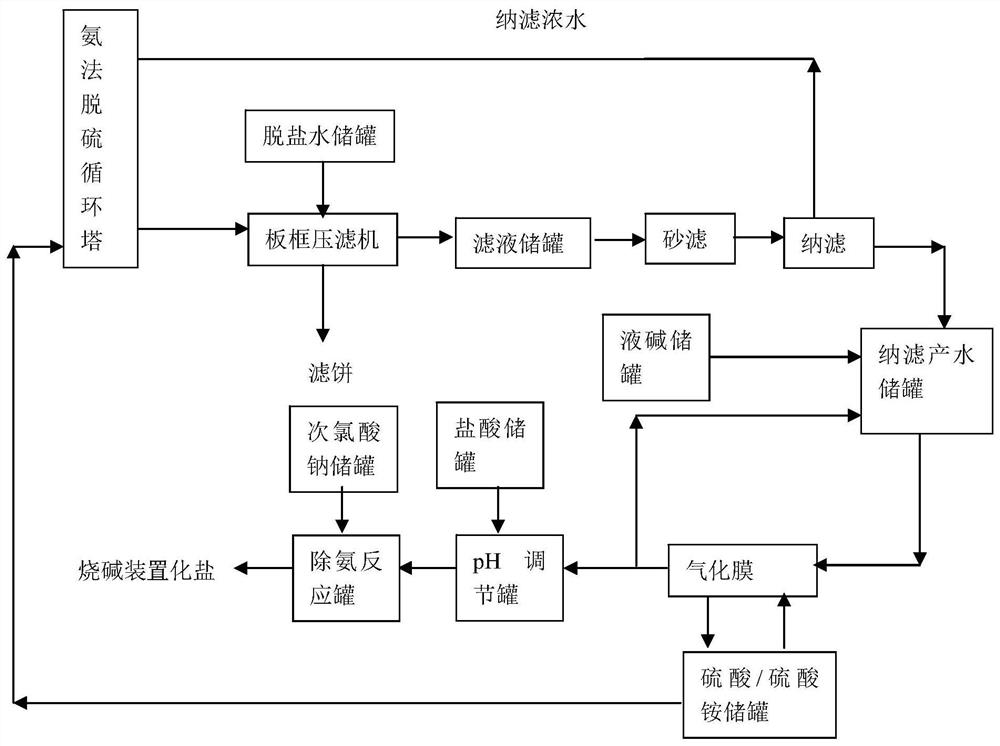

Method for dechlorinating flue gas desulfurization circulating liquid by ammonia method

A technology for circulating liquid and flue gas, applied in the field of chlorine separation, can solve problems such as the inability to separate sulfate radicals and chloride ions, the lack of instructions on how to dispose of ammonia nitrogen, and the lack of instructions on how to dispose of sodium chloride.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Coal-fired power plant ammonia flue gas desulfurization circulation tower, circulating water volume 30m 3 / h, containing 250,000 mg / L of sulfate, 124,500 mg / L of chloride ion, 1,000 mg / L of suspended matter, and pH 9.5. Use a corrosion-resistant pump to pump out the circulating fluid from the circulation tower at a flow rate of 250L / h, continuously pump it for 2 hours, and pump it directly into the silo of the plate and frame filter press, pressurize to 1.0MPa, and the suspended matter becomes mud cake. The desalinated water is used to repeatedly wash the mud cake, and the desalted water consumed by washing is 15 times that of the filtrate, and the inorganic salt in the mud cake is washed until it meets the requirements of landfill. Then continue to pressurize to 1.6MPa, press the mud cake to a water content of 60%, unload the mud cake from the plate and frame filter press, and send it to the fly ash processing unit for disposal. Repeat the plate and frame filter press...

Embodiment 2

[0068] Coal-fired power plant ammonia flue gas desulfurization circulation tower, circulating water volume 50m 3 / h, containing ammonium sulfate 180000mg / L, ammonium chloride 101000mg / L, suspended matter 1500mg / L, pH value 9.0. Use a corrosion-resistant pump to extract the circulating fluid from the circulation tower at a flow rate of 450L / h, continuously pump it for 2 hours, and pump it directly into the silo of the plate-and-frame filter press, pressurize to 1.1MPa, and the suspended matter becomes mud cake. The desalinated water is used to repeatedly wash the mud cake, and the desalted water consumed by washing is 10 times that of the filtrate, and the inorganic salt in the mud cake is washed until it meets the requirements of landfill. Then continue to pressurize to 1.7MPa, press the mud cake to a water content of 60%, unload the mud cake from the plate and frame filter press, and send it to the fly ash processing unit for disposal. Repeat the plate and frame filter press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com