Recombinant humanized collagen and its industrial production method and product application

A collagen and humanization technology, applied in the fields of protein purification and genetic engineering, can solve the problems of water-solubility and hydrophilicity, moisturizing and hygroscopicity, etc., and achieve a significant effect of promoting proliferation, simple control and good effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

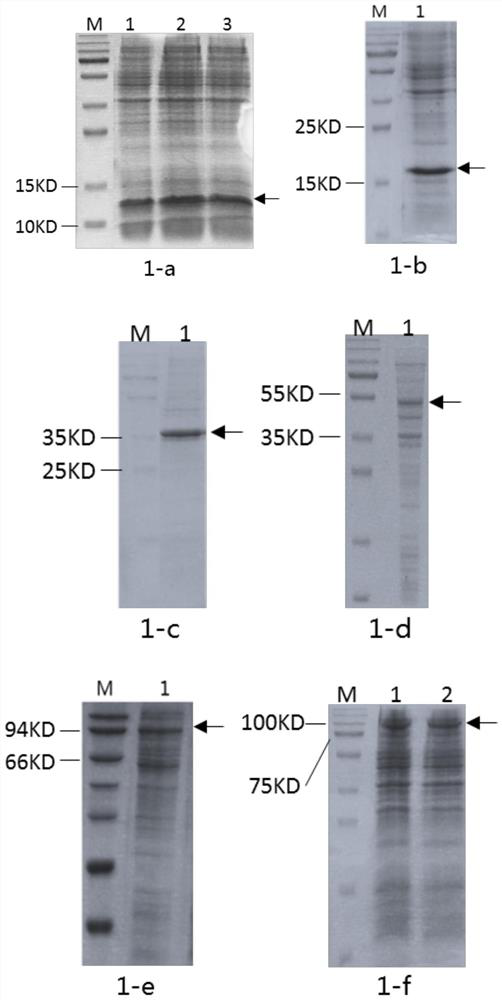

Image

Examples

Embodiment 1

[0047] Example 1 Construction of rHLC Escherichia coli strain

[0048] 1. Obtaining rHLC genes with different repeat numbers

[0049] The rHLCs with different numbers of repeat units were reverse-translated for the amino acid sequence and optimized for E. coli. GenScript Biotechnology Co., Ltd. was entrusted to synthesize their corresponding DNA sequences, and NcoI and 3 were introduced at the 5' end of the DNA during synthesis. ' end introduced XhoI restriction site. The synthesized genes were individually cloned into the pUC57-T-simple vector and delivered as recombinant plasmids.

[0050] 2. Construction of recombinant expression strains

[0051] The rHLC gene was cloned into the pET28a vector to form a recombinant expression vector using the double enzyme digestion and enzyme ligation methods in "Molecular Cloning", and then the recombinant expression vector was transformed into Escherichia coli BL21 (DE3) competent cells by heat shock transformation.

[0052] 3. Expres...

Embodiment 2

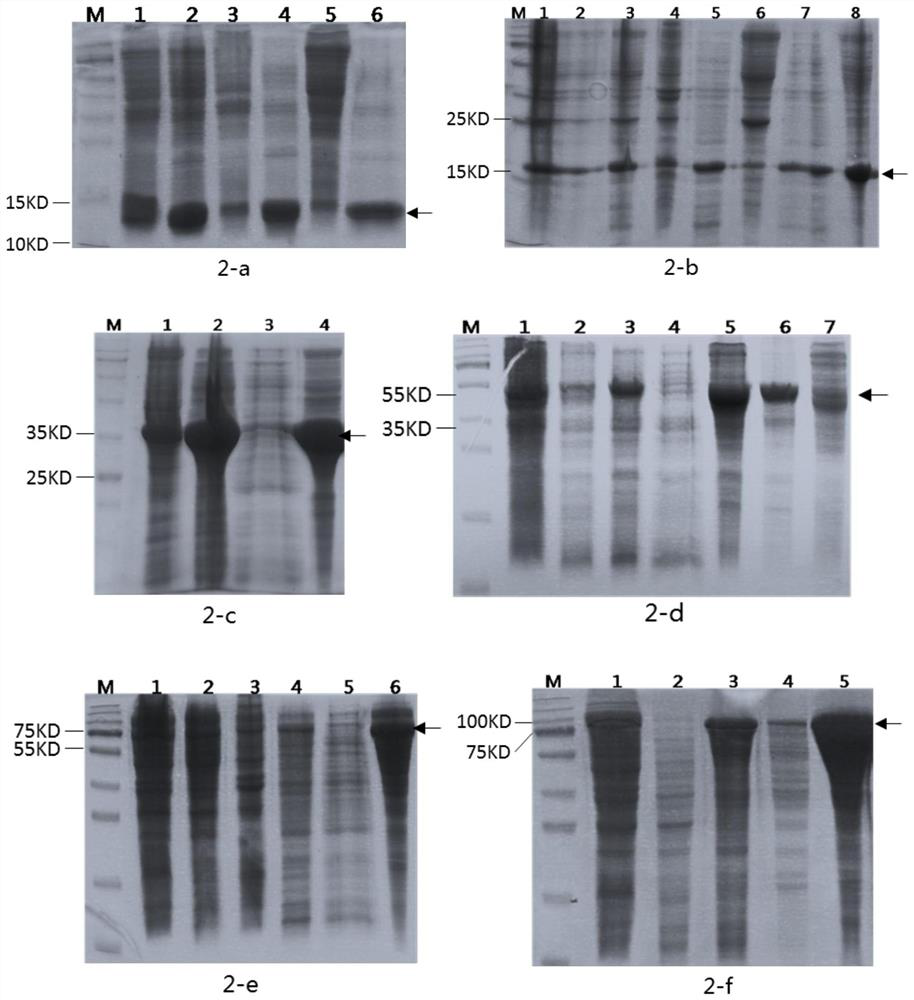

[0054] Example 2 rHLC small-scale fermentation (medium volume 10L)

[0055] This example mainly describes the 10L fermentation process of rHLC. In the fermentation process, glycerol with clear components is used as the carbon source for cell metabolism, and ammonia water is used (both for pH adjustment and as nitrogen source for cell metabolism in the fermentation process) and diammonium hydrogen phosphate as the nitrogen source for cell metabolism; at the same time, in order to promote cell growth, shorten the fermentation cycle, and improve fermentation yield, compound nutrients such as yeast powder and peptone are also added to the medium. The fermenter used was Sartouris cplus fermenter, and the initial volume of fermentation was 10L.

[0056] Specific steps are as follows:

[0057] 1. Preparation of fermented seed liquid: Inoculate the rHLC Escherichia coli strain cryopreservation tube constructed in Example 1 into the LB solid medium containing 50 μg / ml kanamycin using ...

Embodiment 3

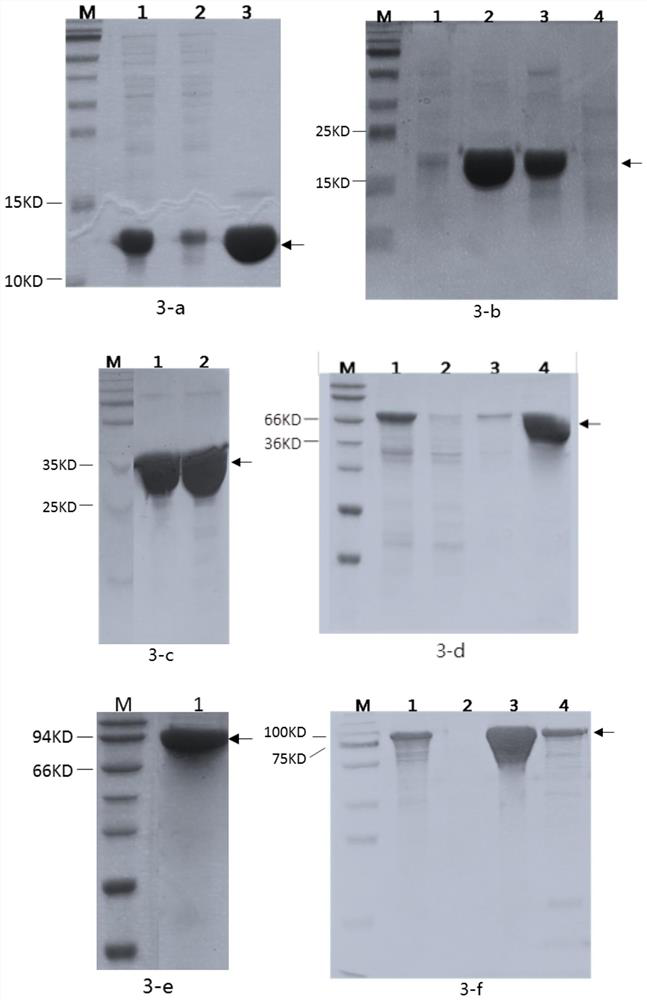

[0064] Example 3 rHLC pilot scale-up fermentation (150L)

[0065] This example describes the amplification of the fermentation process of rHLC, and the research and verification of the pilot scale-up fermentation process is carried out on the basis of the small-scale fermentation process (Example 2). details as follows:

[0066] 1. Obtain secondary seed solution in the same way as in Example 2.

[0067] 2. Prepare 15L basal culture based on in-situ sterilization in a 50L seed tank according to the method in Example 2 and batch medium components, and then inoculate the secondary seed liquid in step 1 into the seed tank for cultivation, and the cultivation conditions are: : Tank pressure=0.3MPa T=37°C D0=40% pH=7.0, use ammonia water to control pH not lower than 7.0, and do not add antibiotics during culture. Cultivated to OD=15-30 can be transferred to the working tank. as a tertiary seed solution.

[0068] 3. Prepare 150L basal culture based on in-situ sterilization in a 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com