Polycation-hyaluronic acid composite hydrogel as well as preparation method and application thereof

A technology of compounding hydrogel and hyaluronic acid, which can be used in pharmaceutical formulations, medical preparations with non-active ingredients, and pharmaceutical sciences, and can solve problems such as unreported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The preparation of embodiment 1 cationic polymer DDP

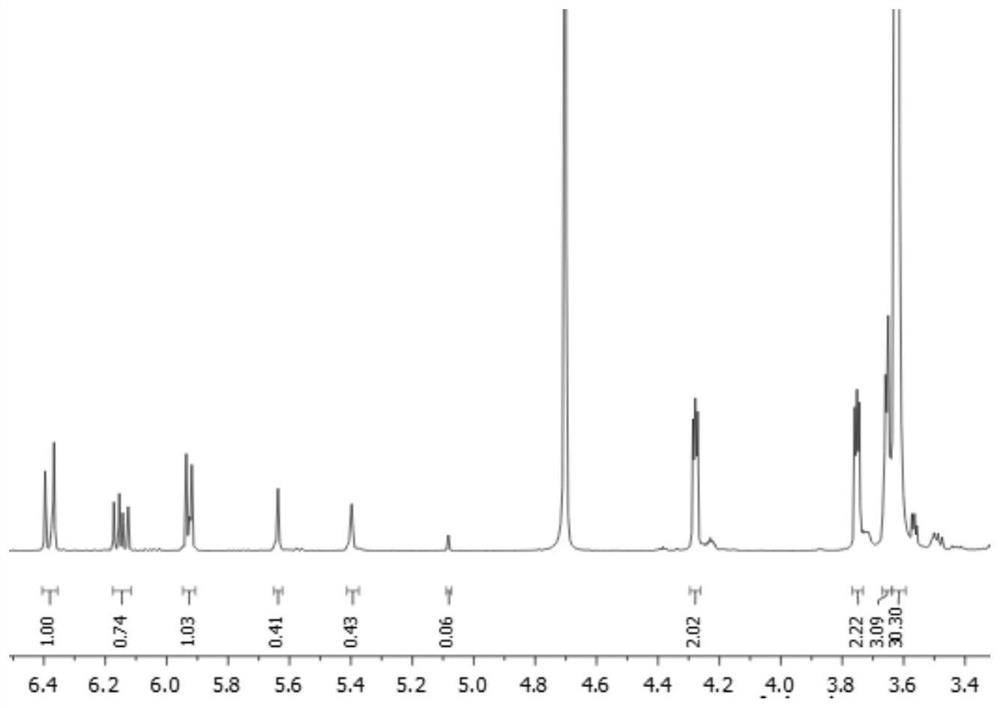

[0050] Dissolve 3.3 g of dopamine methacrylamide in 10 mL of dimethylformamide, and add 5.75 g of polyethylene glycol diacrylate (molecular weight: 575) until completely dissolved. Then add 0.02g AIBN and mix thoroughly, and react at 70°C for 7h. Then the product was added dropwise to 100 mL of ether, and the precipitate was vacuum-dried for 24 hours to obtain polymer DP (the molar ratio of dopamine methacrylamide, polyethylene glycol diacrylate and AIBN was 60:40:1).

[0051] Dissolve 0.55g of dopamine methacrylamide in 10mL of dimethylformamide, add 2.1g of antibacterial cationic monomer N-(3-dimethylaminopropyl)methacrylamide, endow the multifunctional polymer with strong antibacterial sex. Add 5.75 g of polyethylene glycol diacrylate (molecular weight: 575) until completely dissolved. Finally, 0.02g of AIBN was added, mixed well, and electromagnetically stirred in an oil bath at 70°C for 7 hours. The product...

Embodiment 2

[0054] Embodiment 2: Synthesis of highly mercaptolated hyaluronic acid (HA-SH)

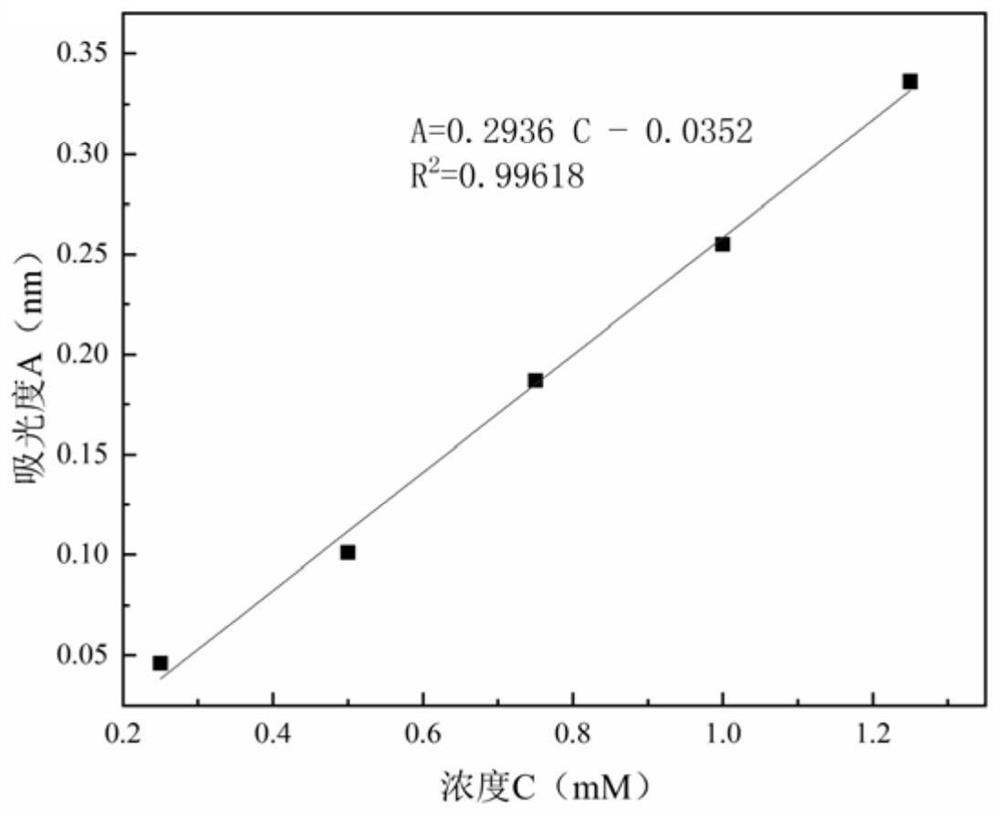

[0055] Propionyl hydrazide method: Weigh 2.0g of hyaluronic acid (molecular weight: 200,000; Tianjin Xinsiopude Technology Co., Ltd.) dissolved in 2.0L of deionized water, then add 2.0g of propionyl hydrazide, 1.9g of 1- (3-Dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (EDC), reacted with electromagnetic stirring at room temperature for 2 hours. Then add 10.0 g of dithiothreitol (DTT) into the mixed solution, mix thoroughly and electromagnetically stir for 24 hours. 1.0M hydrochloric acid was added to adjust the pH of the mixture to 4.0-7.0, and then the mixture was transferred to a 3500D dialysis bag and dialyzed against 0.1M HCl containing 1% (v / v) NaCl. Finally, the solution in the dialysis bag was collected and freeze-dried for 24 hours to obtain 1.97 g of HA-SH with a yield of 98.5%. (Patent CN103613686A only obtains 1.85g HA-SH after lyophilization)

[0056] Cysteamine method: We...

Embodiment 3

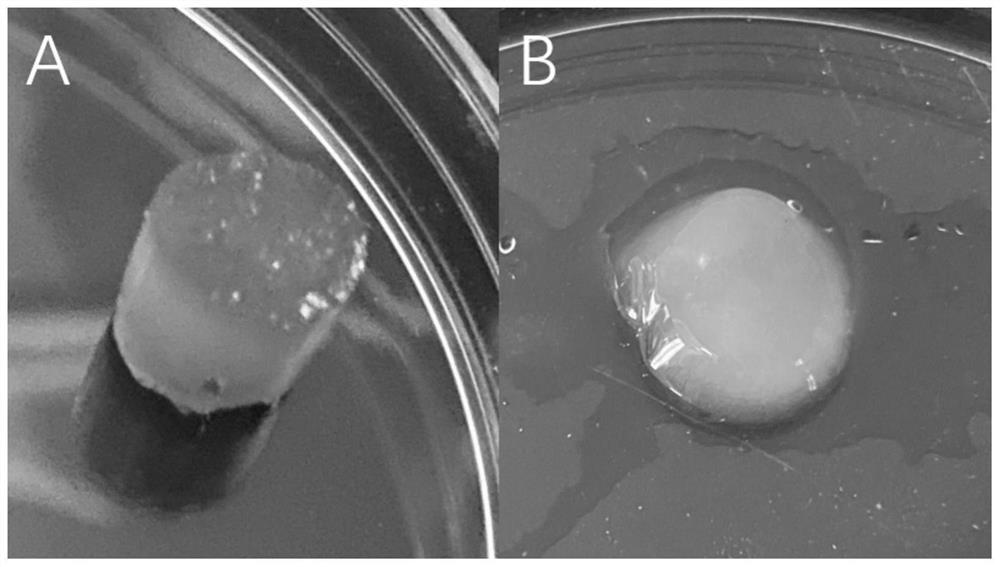

[0059] Embodiment 3: the preparation of polycation-hyaluronic acid composite hydrogel (DDP-HA)

[0060] (1) Preparation of DDP solution: Weigh 0.1g, 0.2g, and 0.3g of the cationic polymer DDP1 prepared in Example 1, respectively, and place them in a glass bottle, add 1mL of 1.0M sodium hydroxide solution, and prepare 10%, 0.3g, and 20%, 30% (m / v) DDP solution, marked as 10DDP, 20DDP, 30DDP.

[0061] (2) Preparation of HA-SH solution: Weigh 0.02-0.08 g of the highly mercaptolated hyaluronic acid prepared by the propionyl hydrazide method in Example 2 and place it in a glass bottle, and add 1 mL of 1×PBS solution to prepare 2- 8% (m / v) HA-SH solution. The mercaptolated hyaluronic acid prepared by the cysteamine method in Example 2 is made into HA-SH solution in the same way.

[0062] (3) Preparation of DDP-HA hydrogel: First, take 1mL of the DDP solution prepared in step (1) in a centrifuge tube, then take 1mL of the two HA-SH solutions prepared in step (2) and place them in g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com