Preparation method of carbon nanotube composite material

A technology of composite materials and carbon nanotubes, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problem of large consumption of hydrogen and carbon source gas, unstable composite material structure, and uneven material particle size, etc. problems, achieving uniform particle size, improving electrochemical reactivity, and uniform diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

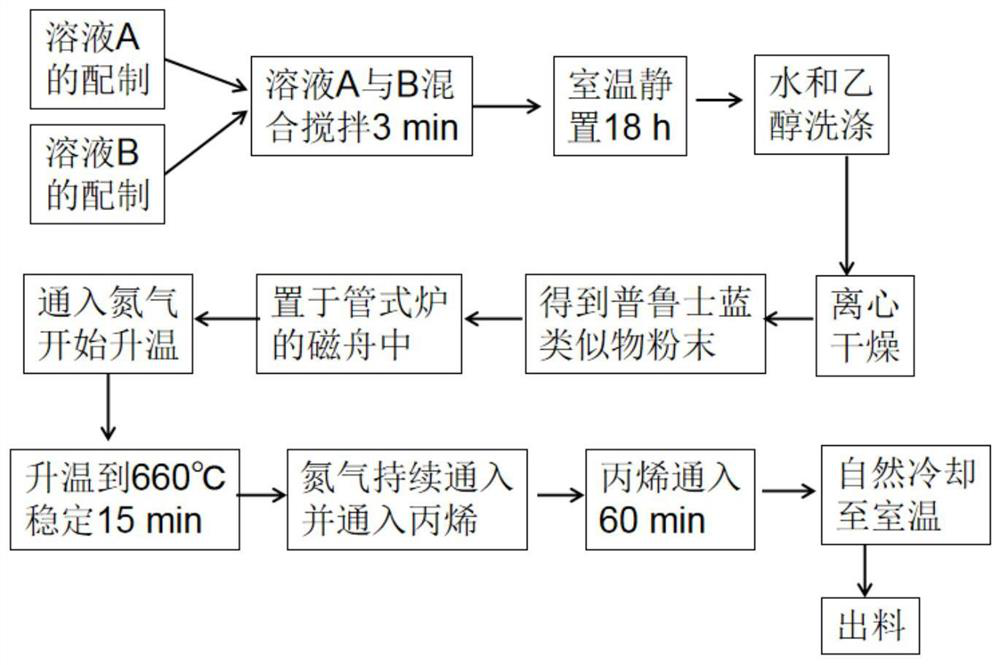

[0018]A method of preparing a carbon nanotube composite, including the following steps:

[0019](1) CO-Ni PBA, prepared by normal temperature precipitation method, is a precursor: the preparation method of the CO-NIPBA includes the following steps: Steps 1, 2.4 mmol Cobalt chloride and 1.05 mol of citric acid Sod is dissolved in 60 ml of deionized water to form a solution A; Step 2, 1.2 mmol tetragonyl nickel nickel acid potassium dissolved in 60 mL of deionized water to form a solution B; step three, solution A and solution B mixed with magnetic force for 3 minutes, room temperature 18H, water and ethanol were washed, 70 ° C for 12 h, resulting in CO-Ni PBA powder.

[0020](2) Preparation of carbon nanotube composites: Prussia Blue analog Co-Ni PBA powder is placed in a tube furnace in a tube furnace in a magnetic boat, continuously introducing nitrogen, and has a nitrogen flow rate of 0.5L min.-1When the temperature rises to 660 ° C and stabilizes 15 min; accelerates propylene, propylen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com