Method for enhancing methane production through biogas fermentation by reinforcing carbon dioxide utilization through fermentation separation coupling integration

A technology of fermentation separation coupling and bio-natural gas, applied in the biological field, can solve the problems of increasing production costs, supporting equipment and high operating requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Trichoderma reesei fermentation bacteria enzyme solution preparation:

[0030] The substratum composition that is used to prepare Trichoderma reesei fermentation bacteria enzyme liquid comprises: 10g / L glucose, 20g / L wheat bran, 1g / L peptone, 0.3g / L urea, 2.8g / L (NH 4 ) 2 SO 4 , 4g / L KH 2 PO 4 , 0.6g / L MgSO 4 ·7H 2 O, 0.8g / L CaCl 2 , 0.01g / L FeSO 4 ·7H 2 O, 0.004g / L MnSO 4 ·H 2 O, 0.03g / L ZnSO 4 ·7H 2 O, 0.005g / L CoCl 2 , 0.2mL / L Tween 80.

[0031] The above liquid medium was sterilized at 121° C. for 15 minutes, and after cooling to room temperature, Trichoderma reesei spore liquid (wild type or genetically engineered recombinant Trichoderma reesei) was inoculated in the medium at 10% by volume. 28°C, 400rpm, control pH 4.5, control dissolved oxygen 20%, control glucose concentration not higher than 0.5g / L, cultivate for 6 days, and then get wild-type Trichoderma reesei Rut C30 fermented enzyme liquid or high-yielding fiber Genetic engineering recomb...

Embodiment 2

[0036] Using corn stalks and duck manure as bio-natural gas fermentation materials, first add the wild-type Trichoderma reesei Rut C30 fermentation bacteria enzyme solution in the above-mentioned Example 1 according to the solid-to-liquid ratio of 1:8 of the stalks, and pretreat the stalks 5 after mixing evenly After 1 day, mix with duck manure again to obtain straw mixed solid waste; then add the Clostridium carbon monoxide fermented bacteria liquid in the above-mentioned embodiment 1 according to 15% of the quality of straw mixed solid waste, mix evenly and place it in a working volume of 3L Bio-natural gas fermentation is carried out in a solid-state fermentation reactor. In this embodiment, the solid-state fermentation reactor is equipped with a temperature control device, but there is no gas circulation and reflux device, that is, the carbon dioxide generated in this embodiment does not circulate and reflux to the fermentation system. Oxygen in the fermentation system was...

Embodiment 3

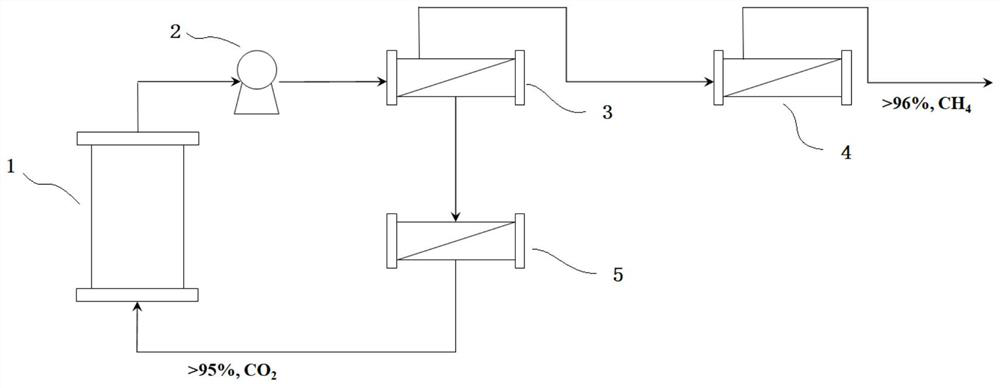

[0039]Using corn stalks and duck manure as bio-natural gas fermentation materials, first add the recombinant Trichoderma reesei (CGMCCNo. 12768) fermented bacteria enzyme liquid, mixed evenly and pretreated the stalks for 5 days, then mixed with duck manure to obtain straw mixed solid waste; then add the carbon monoxide shuttle in the above-mentioned embodiment 1 by 15% of the quality of the straw mixed solid waste Bacteria fermentation broth, mixed evenly and placed in a solid-state fermentation reactor with a working volume of 3L for bio-natural gas fermentation. In this embodiment, the solid-state fermentation reactor is equipped with a temperature control device, and the bottom of the reactor is equipped with a gas reflux device. After the fermentation gas is separated and purified by the gas separation membrane system, the remaining carbon dioxide can be recycled to the fermentation system (such as figure 1 shown). Before the bio-natural gas fermentation starts, nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com