Treatment method of waste etching liquid

A treatment method and etching solution technology, applied in the field of waste treatment, can solve the problems of distillation equipment maintenance and large footprint, cumbersome and complicated treatment process, and difficult organic solvent treatment, so as to achieve electron economy and element economy , high economic and environmental benefits, and the effect of improving the electrocatalytic reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The embodiment of the present application provides a method for treating waste etching solution, comprising the following steps:

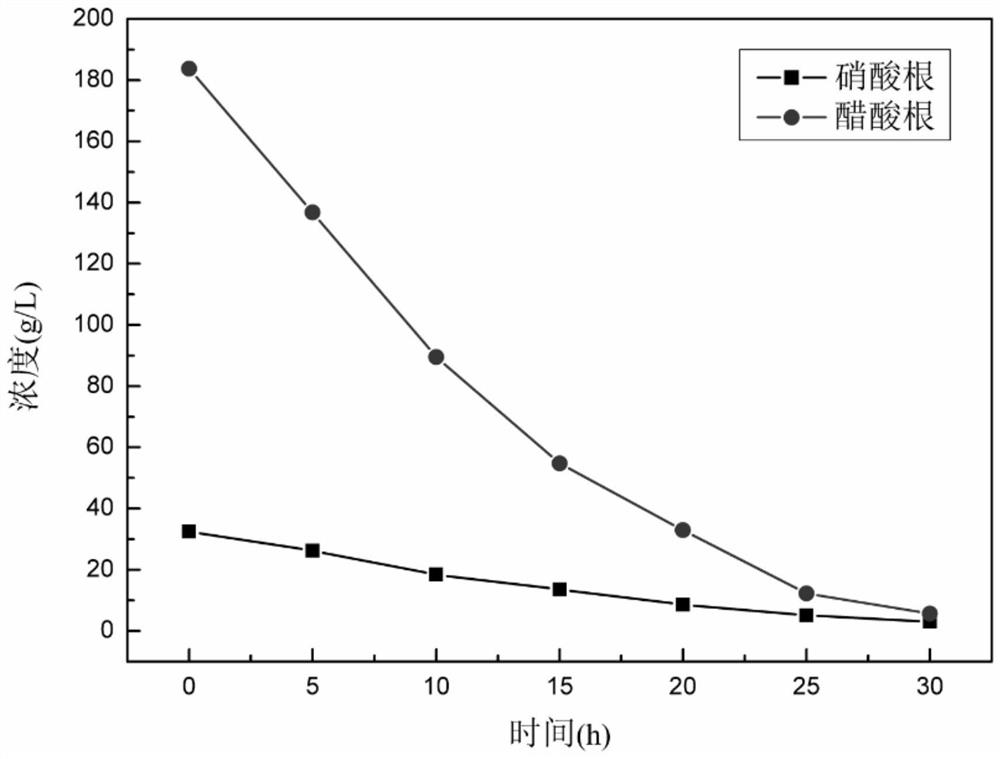

[0062] A1, get the waste etching solution of 300ml, wherein, the hydrogen ion concentration of waste etching solution is 4.6774mol / L, and the concentration of nitrate in the waste etching solution is 32.50g / L, and mass fraction is 2.18%; The concentration is 417.95g / L, and the mass fraction is 28.07%; the concentration of acetate is 183.77g / L, and the mass fraction is 12.34%;

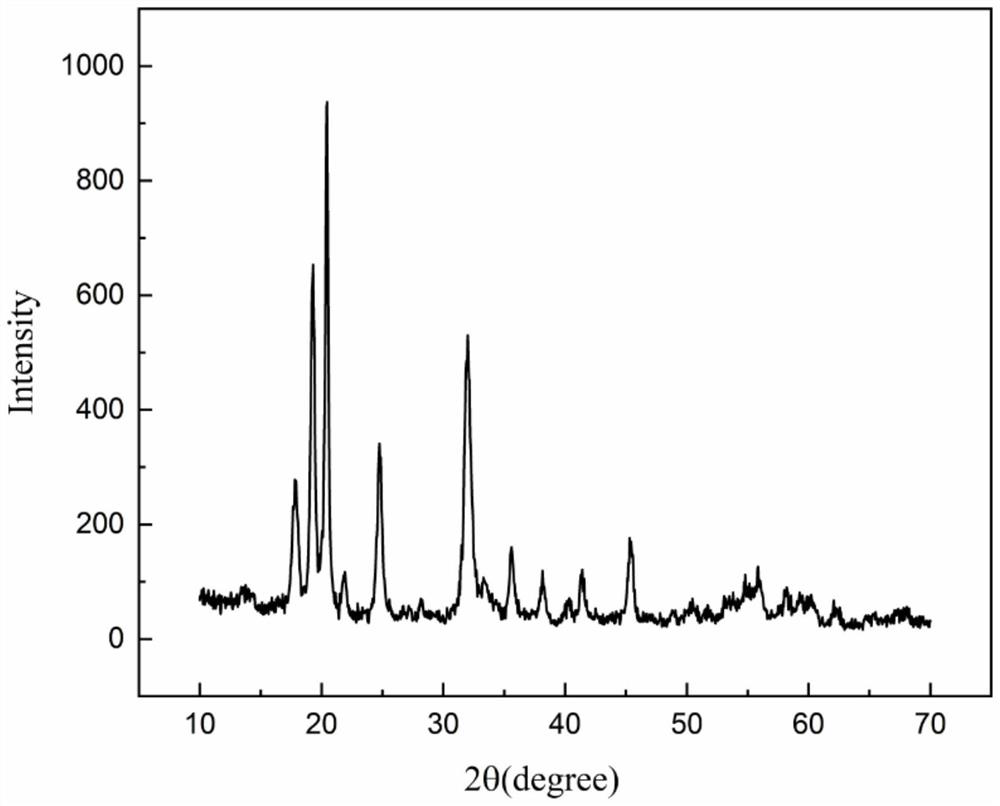

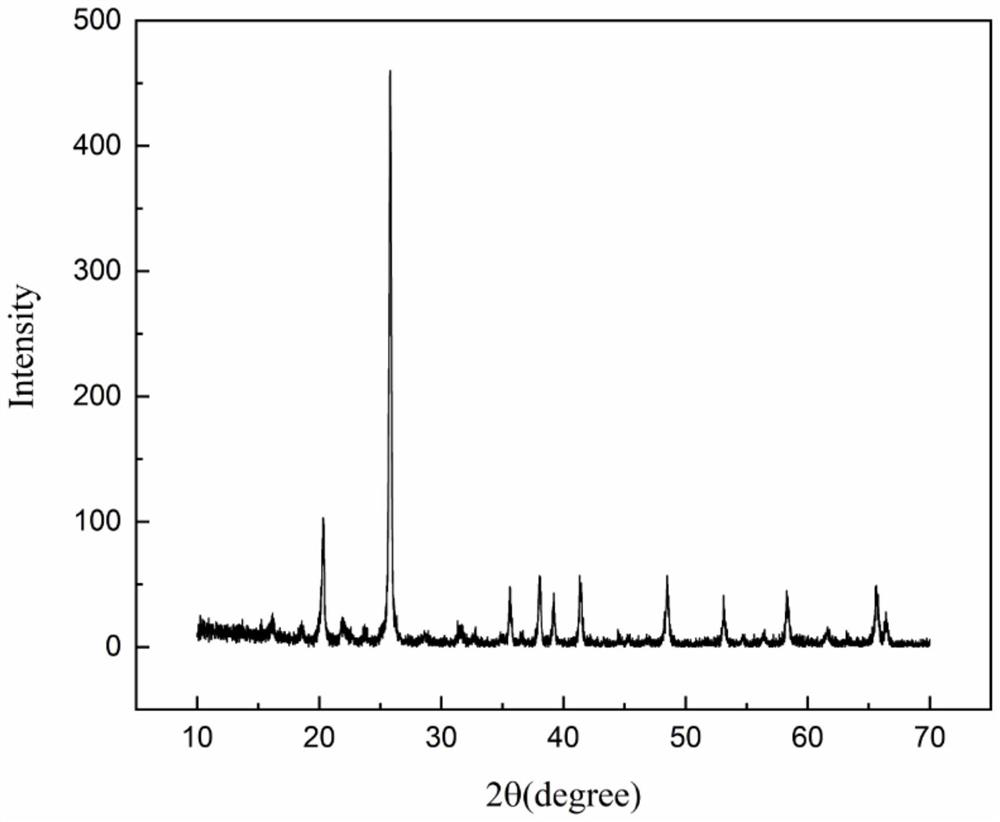

[0063] A2. Place the above waste etching solution in a 500ml electrolytic cell of the electrolysis device for electrolysis. The time for electrolytic impurity removal and precipitation is 30 hours. The cathode material is a carbon cloth electrode sprayed with platinum coating, and the current density of the cathode is 250A / m 2 , the anode material is iron sheet, and the current density of the anode is 310A / m 2 ; During the electrolysis process, nitric acid is reduced...

Embodiment 2

[0071] The embodiment of the present application provides a method for treating waste etching solution, comprising the following steps:

[0072] A1, get 300ml of waste etching solution, wherein, the hydrogen ion concentration of the waste etching solution is 15.8489mol / L, the concentration of nitrate is 53.64g / L, and the mass fraction is 3.6%; the concentration of phosphate is 394.58g / L L, the mass fraction is 26.51%; the concentration of acetate is 187.49g / L, and the mass fraction is 12.60%;

[0073] A2. Place the above waste etching solution in a 500ml electrolytic cell of the electrolysis device for electrolysis. The time for electrolytic impurity removal and precipitation is 48 hours. The cathode material is a carbon cloth electrode sprayed with platinum coating, and the current density of the cathode is 200A / m 2 , the anode material is iron sheet, and the current density of the anode is 280A / m 2; During the electrolysis process, nitric acid is reduced to ammonia nitrogen...

Embodiment 3

[0079] The embodiment of the present application provides a method for treating waste etching solution, comprising the following steps:

[0080] A1, get 300ml of waste etching solution, wherein, the hydrogen ion concentration of the waste etching solution is 7.2444mol / L, the concentration of nitrate is 45.03g / L, and the mass fraction is 3.02%; the concentration of phosphate is 436.53g / L L, the mass fraction is 29.32%; the concentration of acetate is 185.32g / L, and the mass fraction is 12.45%;

[0081] A2. Place the above waste etching solution in a 500ml electrolytic cell of the electrolysis device for electrolysis. The time for electrolytic impurity removal and precipitation is 24 hours. The cathode material is a carbon cloth electrode sprayed with platinum coating, and the current density of the cathode is 260A / m 2 , the anode material is iron sheet, and the current density of the anode is 320A / m 2 ; During the electrolysis process, nitric acid is reduced to ammonia nitroge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com