Corannulene perovskite solar cell hole transport layer material and preparation method and application thereof

A solar cell and hole transport layer technology, applied in the field of solar cell materials, can solve the problems of high production cost, low photoelectric conversion efficiency, and difficulty in meeting people's use needs, achieve high glass transition temperature, improve stability and photoelectricity Effect of Conversion Efficiency, Good Solubility and Electron Donating Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

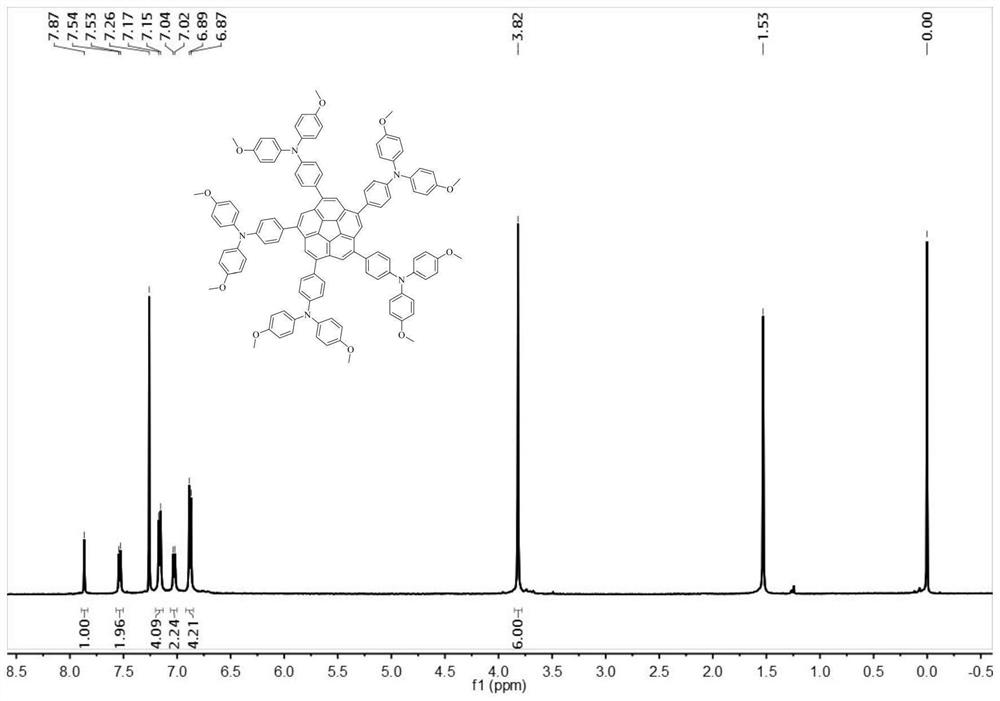

[0039] The structural formula of the hole-transporting layer material of the cowannyl perovskite solar cell of this embodiment is:

[0040]

[0041] The synthetic route is as follows:

[0042]

[0043] Weigh 100mg (0.114mmol) pentaboronyl substituted corannene, 240mg (0.627mmol) compound 1, 181mg (1.71mmol) sodium carbonate and 26mg (0.0228mmol) tetrakistriphenylphosphine palladium in a 50mL dry two-necked bottle, drum Nitrogen evacuation was repeated three times or more to create an anhydrous and oxygen-free reaction environment. Then 20 mL of toluene was added as the reaction solvent, the reaction device was placed in an ultrasonic instrument at room temperature and sonicated for about 10 min, and then the reaction device was placed on a magnetic stirrer and the temperature was raised to 40°C for overnight reaction. During the reaction, the color of the solution gradually deepened. After the reaction was completed, an appropriate amount of ammonium chloride solution w...

Embodiment 2

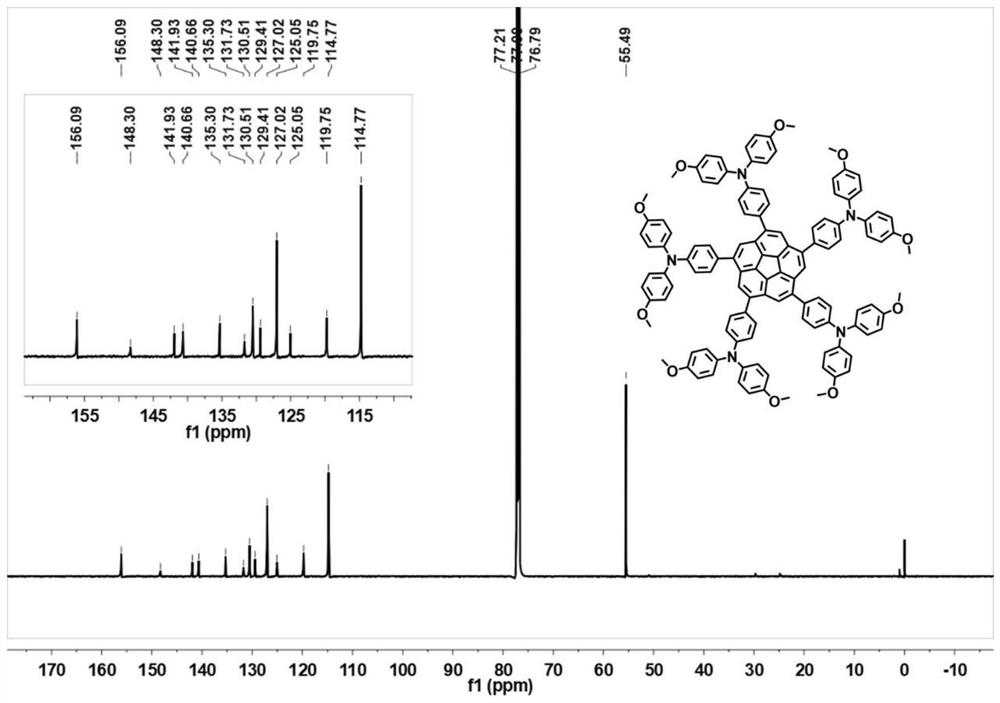

[0045] The structural formula of the hole-transporting layer material of the cowannyl perovskite solar cell of this embodiment is:

[0046]

[0047] The synthetic route is as follows:

[0048]

[0049] (1) First weigh 1g (4.76mmol) compound 1, 1.83g (4.76mmol) thiophene-2-boronic acid pinacol ester, 1.52g (14.3mmol) sodium carbonate and 35.7mg (0.0309mmol) tetrakistriphenylphosphine Palladium was placed in a 500mL dry two-necked bottle, and vacuum pumped with nitrogen was repeated three times or more to create an anhydrous and oxygen-free reaction environment. Subsequently, 150 mL of toluene was added as a reaction solvent, the temperature was raised to 40° C., and the reaction was heated and stirred for 2 h, and the color of the solution changed from yellow to black. After the reaction was completed, the reaction was quenched with ammonium chloride solution, extracted with dichloromethane, the organic phase was washed three times with water, dried with anhydrous sodium...

Embodiment 3

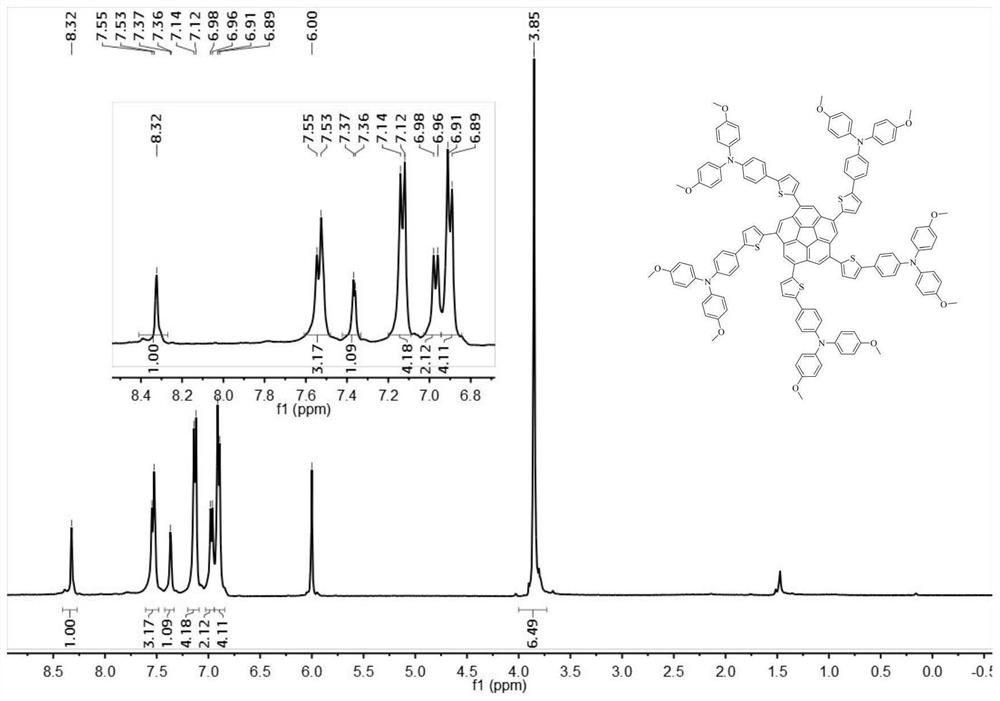

[0053] The structural formula of the hole-transporting layer material of the cowannyl perovskite solar cell of this embodiment is:

[0054]

[0055] The synthetic route is as follows:

[0056]

[0057] Take a 5mL two-necked flask, a spherical condenser and a magnet of appropriate size and place it in an oven at a temperature of 70-80°C for about 30 minutes, and quickly weigh 15 mg (0.017 mmol, 1eq), 4,4'-dimethoxydiphenylamine 42.9mg (0.187mmol, 11eq), B(OH) 3 (boric acid) 10.5mg (0.17mmol, 10eq), Cu(OAc) 2 (Copper acetate) 3.4mg (0.017mmol, 1eq) into a two-necked flask, set up a reaction system and apply a small amount of vacuum grease to the joints of the above components, add 2mL DMSO (dimethyl sulfoxide), and place the reaction device in an ultrasonic instrument Medium sonication for 10 min to disperse the solid evenly in the DMSO solvent. After the ultrasonication is completed, the temperature is raised to 85°C after connecting the condensate pipe, and the reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com