NiCoP-g-C3N4/CdS composite photocatalyst as well as preparation method and application thereof

A nicop-g-c3n4, g-c3n4 technology, applied in the field of composite photocatalysis, can solve the problems of small number of active sites, low photocatalytic performance of composite catalysts, etc., and achieve high-efficiency hydrogen evolution performance and stability, excellent morphology characteristics , The effect of high hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Preparation of g-C 3 N 4 : Put 20g of urea compactly in a crucible, calcined at 500°C for 2h, then calcined at 520°C for 6h, and cooled to room temperature to obtain g-C 3 N 4 .

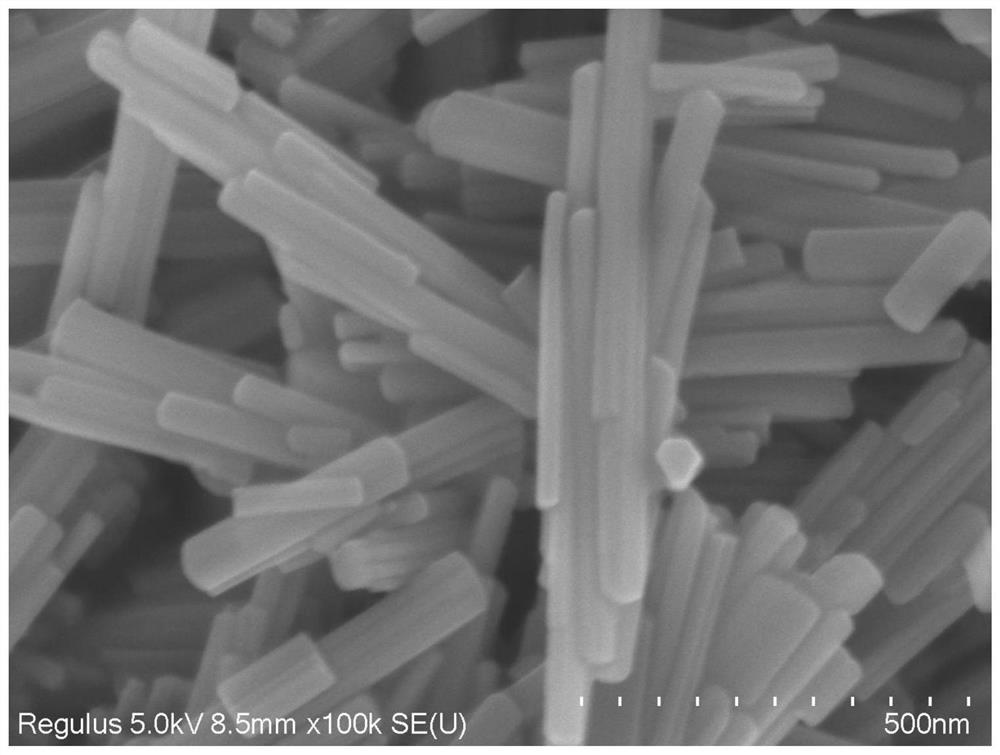

[0039] 2. Preparation of CdS: 2.312g CdCl 2 2.5H 2 O and 2.312 g NH 2 CSNH 2 Added into a 50mL Teflon-lined autoclave containing 30mL ethylenediamine, stirred for 10min and then sonicated for 10min. The autoclave was then heated to 160 °C and maintained for 48 h. The yellow product was collected, washed three times with deionized water and ethanol respectively, and the speed of the centrifuge was 10000r / min. Finally, the CdS was obtained by drying in an oven at 70°C.

[0040] 3. Preparation of g-C 3 N 4 / CdS: Accurately weigh 40mg of g-C 3 N 4 , and dispersed in 30mL of methanol. The above suspension was ultrasonically treated for 1 hour to obtain a homogeneous suspension, then, 2 g of CdS was added into the suspension, and the stirring was continued for 24 h. Finally, the co...

Embodiment 2

[0044] Steps 1-3 are the same as in Example 1.

[0045] 4. Preparation of 5% NiCoP-g-C 3 N 4 / CdS: Separately mix 24mg of NiCl 2 ·6H 2 O, 24mg of Co(NO 3 ) 2 ·6H 2 O and 120 mg NaH 2 PO 2 Dissolve in a beaker containing 10mL of water and stir to dissolve completely. After weighing 300mg of g-C 3 N 4 / CdS was added to the solution and sonicated for 1 h. Then, put the mixed product into an oven at 70°C for drying, fully drying the water completely. The ground product was then calcined in a tube furnace under N 2 Under protection, the temperature was raised to 300° C. at a rate of 5° C. / min, and calcined for 1 h, and then allowed to cool naturally to room temperature. Finally, it was washed three times with ultrapure water and absolute ethanol, and the speed of the centrifuge was 10000r / min. Put it in a 60°C oven and dry it for 12h to get 5%NiCoP-g-C 3 N 4 / CdS.

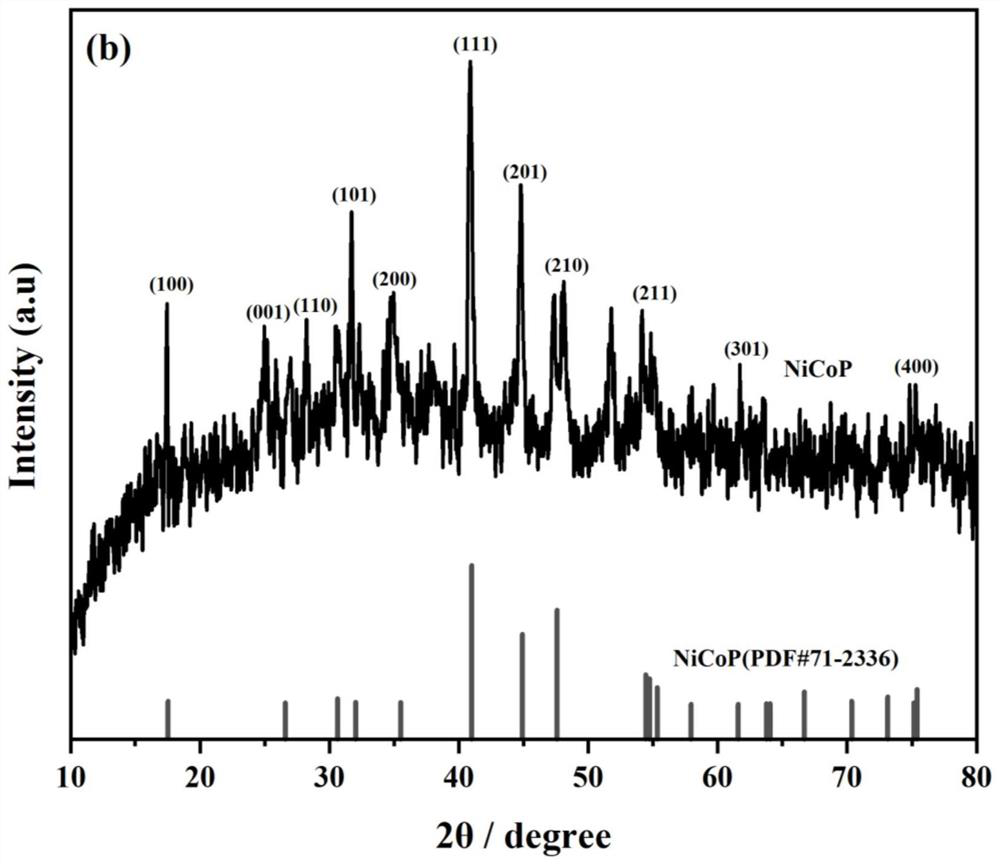

[0046] 5. Preparation of pure NiCoP: 24 mg of NiCl 2 ·6H 2 O, 24mg of Co(NO 3 ) 2 ·6H 2 O and 1...

Embodiment 3

[0049] Steps 1-3 are the same as in Example 1.

[0050] 4. Preparation of 7% NiCoP-g-C 3 N 4 / CdS: 33.6mg of NiCl 2 ·6H 2 O, 33.6 mg of Co(NO 3 ) 2 ·6H 2 O and 168 mg of NaH 2 PO 2 Dissolve in a beaker containing 10mL of water and stir to dissolve completely. After weighing 300mg of g-C 3 N 4 / CdS was added to the solution and sonicated for 1 h. Then, put the mixed product into an oven at 70°C for drying, fully drying the water completely. The ground product was then calcined in a tube furnace under N 2 Under protection, the temperature was raised to 300° C. at a rate of 5° C. / min, and calcined for 1 h, and then allowed to cool naturally to room temperature. Finally, it was washed three times with ultrapure water and absolute ethanol, and the speed of the centrifuge was 10000r / min. Put it in a 60°C oven and dry it for 12h to get 7%NiCoP-g-C 3 N 4 / CdS.

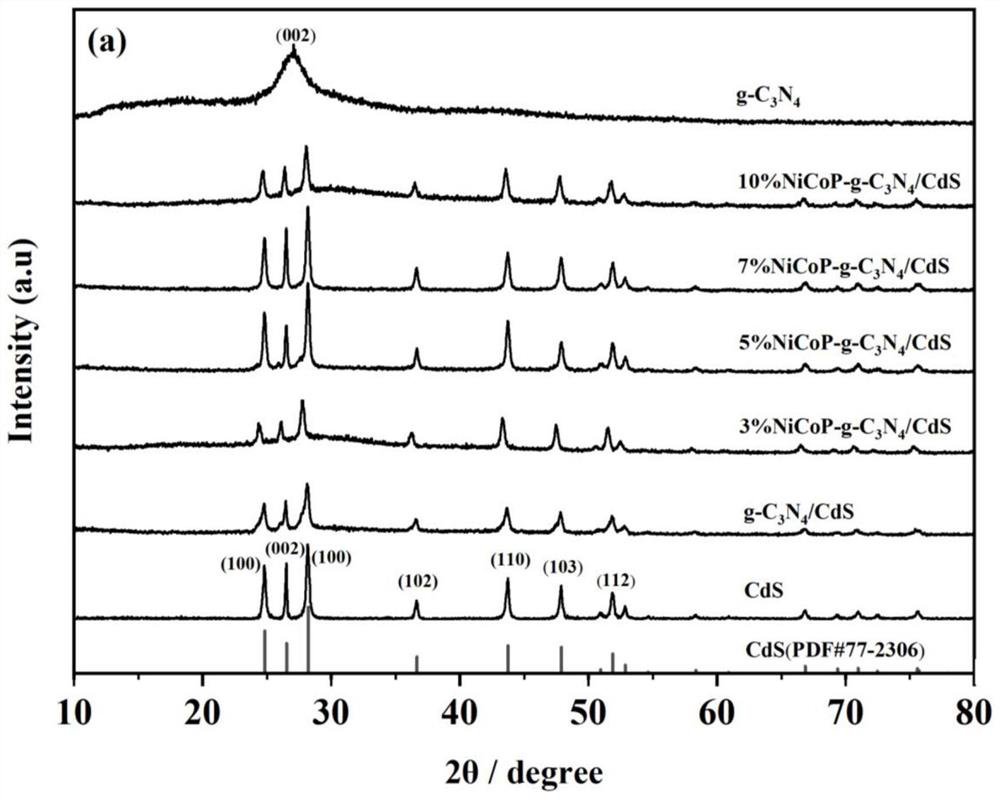

[0051] 5. 7% NiCoP-g-C 3 N 4 The XRD pattern of / CdS (such as figure 1 ), showing a diffraction peak sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com