Preparation process of thermal insulation exterior wall brick

A thermal insulation exterior wall and preparation process technology, which is applied in the field of thermal insulation exterior wall brick preparation technology, can solve the problems of insignificant improvement of thermal insulation performance of sintered wall materials, poor plasticity of sludge incineration ash, and unsuitability for sintered thermal insulation bricks, etc., to achieve Improve thermal insulation, compressive strength and frost resistance, improve flocculation effect, and reduce the release of sulfur gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

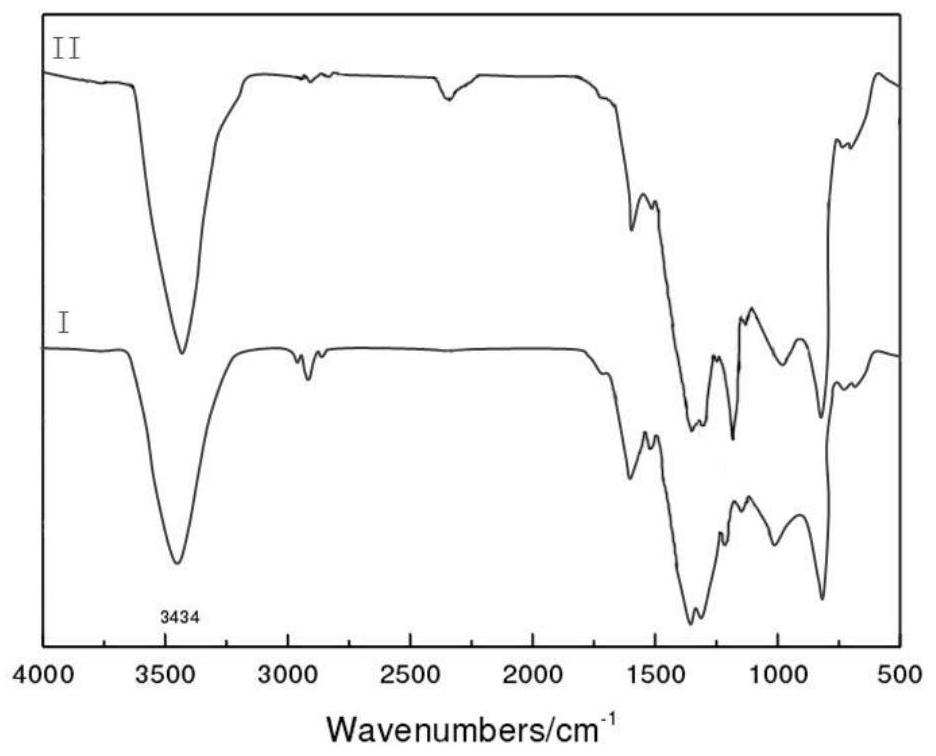

[0062] 1. Modified basalt fiber, obtained by the following methods:

[0063] Put the 200-mesh basalt fiber in 1mol / L HCl solution, soak it at 40°C for 1 hour, and then wash it with deionized water until neutral;

[0064] Add dopamine hydrochloride, diaminophosphoric acid and basalt fiber into the Tris-HCl buffer, the pH of the Tris-HCl buffer is 8.5, ultrasonically disperse for 2 hours to obtain a dispersion, the content of dopamine in the dispersion is 1.8g / L, diaminophosphoric acid The content of the basalt fiber is 0.12g / L, and the content of the basalt fiber is 3.5g / L. After standing for 24 hours, the basalt fiber is taken out, washed repeatedly with deionized water, and vacuum-dried to obtain the modified basalt fiber.

[0065] 2. A treatment method for municipal sludge, comprising,

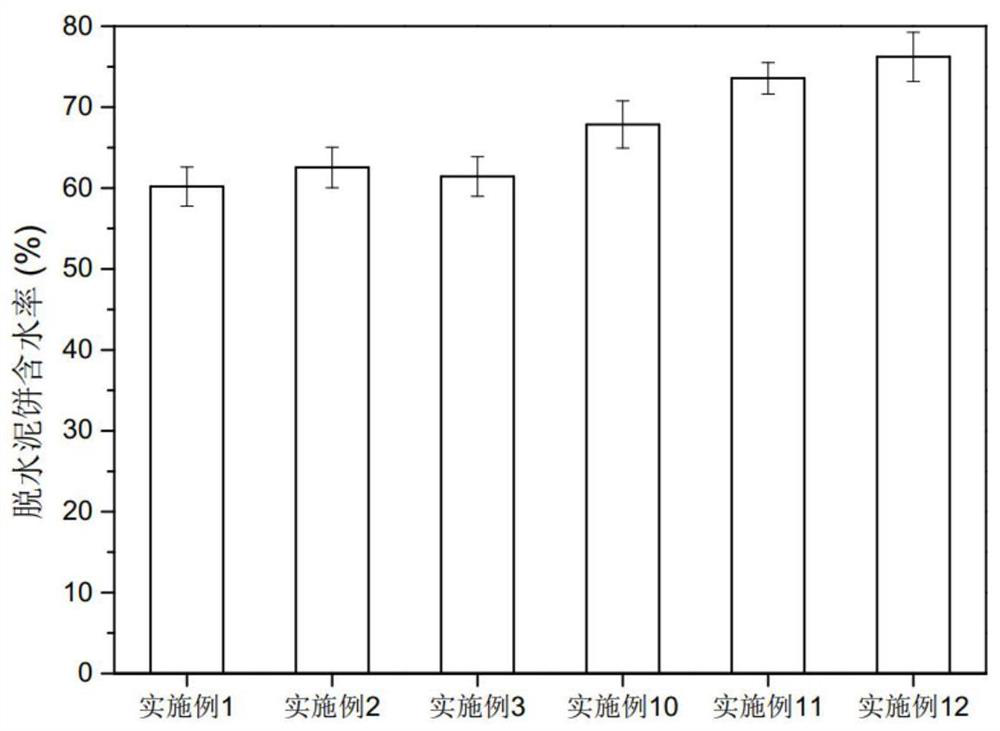

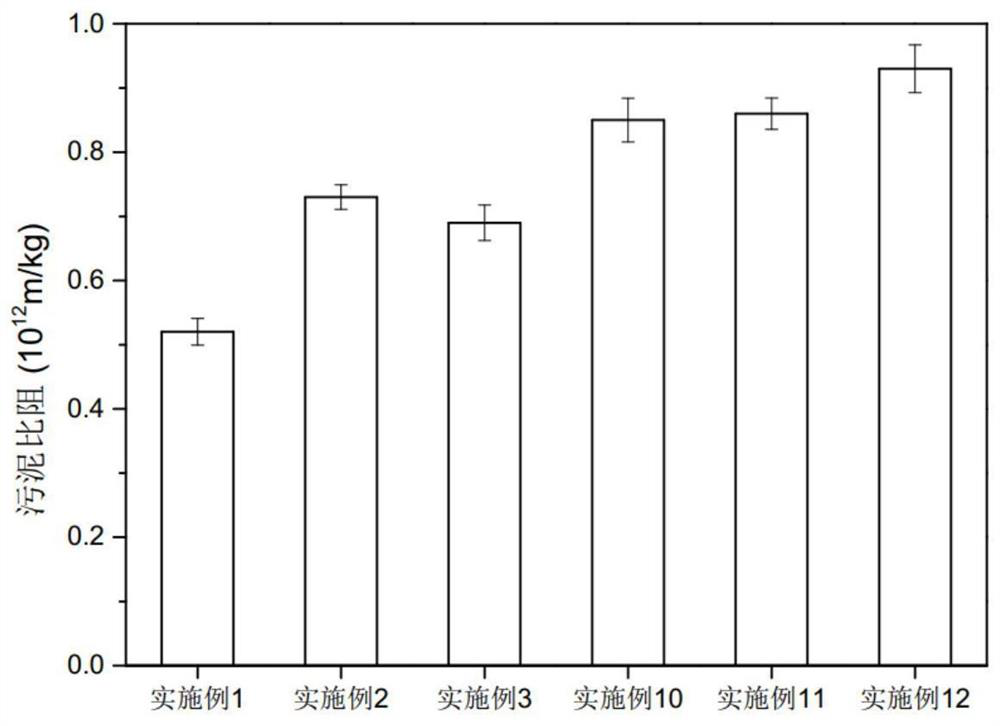

[0066] Step 1, based on the weight of sludge dry basis, add 3% modified basalt fiber and 0.3% polyacrylamide to municipal sludge (its basic properties are shown in Table 1), first stir rapi...

Embodiment 2

[0076] 1. Modified basalt fiber, obtained by the following methods:

[0077] Put the 200-mesh basalt fiber in 1mol / L HCl solution, soak it at 40°C for 1 hour, and then wash it with deionized water until neutral;

[0078] Add dopamine hydrochloride, diaminophosphoric acid and basalt fiber into the Tris-HCl buffer, the pH of the Tris-HCl buffer is 8.5, and ultrasonically disperse for 2 hours to obtain a dispersion. The content of dopamine in the dispersion is 1.2g / L, and the diaminophosphoric acid The content of the basalt fiber is 0.05g / L, and the content of the basalt fiber is 2g / L. After standing for 20 hours, the basalt fiber is taken out, washed repeatedly with deionized water, and vacuum-dried to obtain the modified basalt fiber.

[0079] 2. A treatment method for municipal sludge, comprising,

[0080] Step 1, based on the weight of the sludge dry basis, add 1.5% modified basalt fiber and 0.1% polyacrylamide to the municipal sludge (its basic properties are shown in Table...

Embodiment 3

[0088] 1. Modified basalt fiber, obtained by the following method:

[0089] Put the 200-mesh basalt fiber in 1mol / L HCl solution, soak it at 40°C for 1 hour, and then wash it with deionized water until neutral;

[0090] Add dopamine hydrochloride, diaminophosphoric acid and basalt fiber into the Tris-HCl buffer solution, the pH of the Tris-HCl buffer solution is 8.5, and ultrasonically disperse for 1-2 hours to obtain a dispersion liquid. The content of dopamine in the dispersion liquid is 2g / L, diamino The content of phosphoric acid was 0.3g / L, and the content of basalt fiber was 5g / L. After standing for 24 hours, the basalt fiber was taken out, washed repeatedly with deionized water, and dried in vacuum to obtain modified basalt fiber.

[0091] 2. A treatment method for municipal sludge, comprising,

[0092] Step 1, based on the weight of sludge dry basis, add 4% modified basalt fiber and 0.45% polyacrylamide to municipal sludge (its basic properties are shown in Table 1), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| loss rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com