Anaerobic dehalogenation microbial agent and amplified production method thereof

A production method and technology of halogenated bacteria agent, applied in the field of actual site restoration of halogenated organic matter, can solve the problems of complex production operation of anaerobic dehalogenation bacteria, high anaerobic requirements of anaerobic dehalogenation bacteria, and difficulty in large-scale production. , to achieve the effect of low cost, improved efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

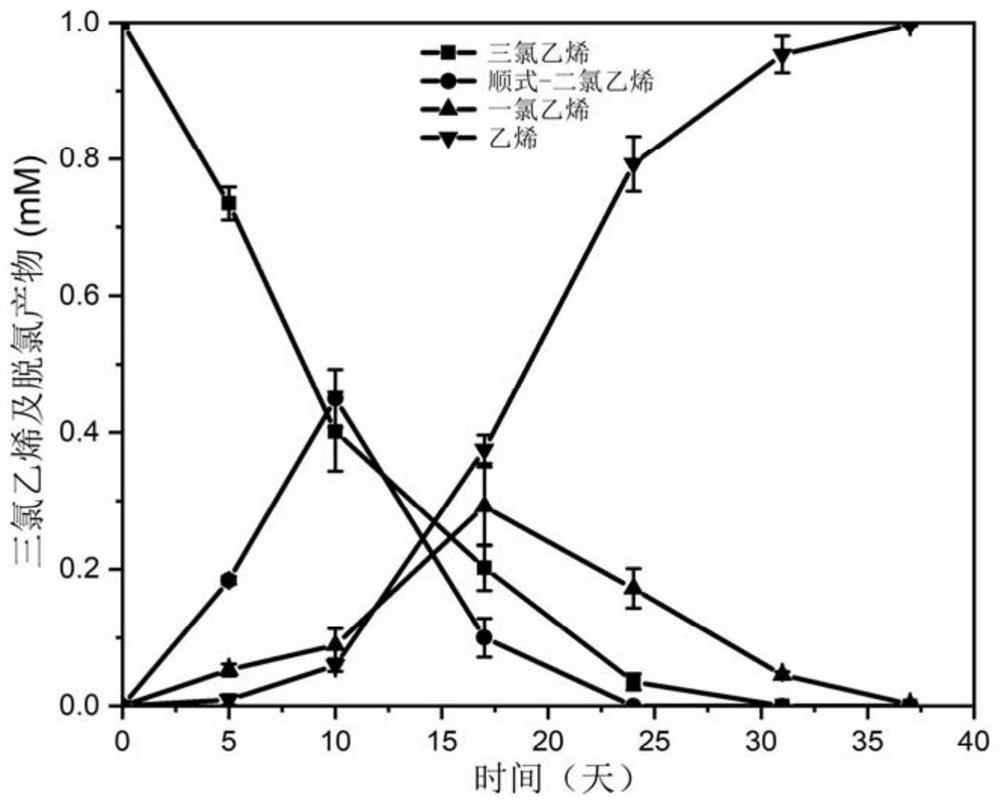

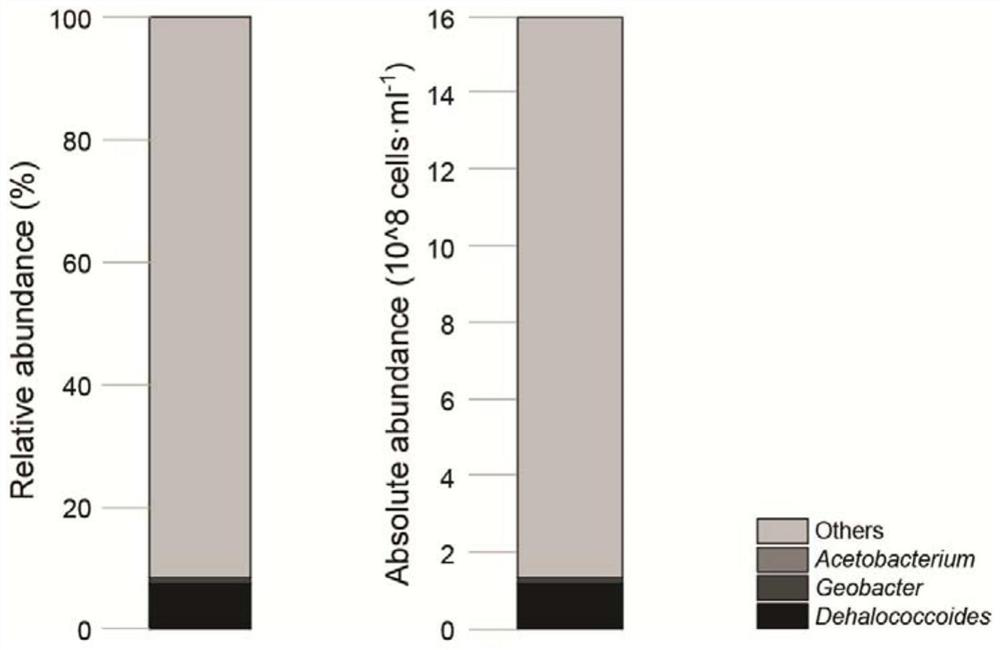

Embodiment 1

[0055] A kind of amplified production method of anaerobic dehalogenation bacteria agent, concrete steps are: select 20L polyethylene small-mouth plastic barrels, install the tap water that volume ratio is 98.92%, add the sodium bicarbonate of 30mM concentration successively as pH buffering agent, 360mg / L COD cassava flour (180mg / L COD) and sludge digestion supernatant (180mg / LCOD) mixture, the volume fraction is 0.08% anaerobic digestion sludge, then wrapped with a parafilm, and cultivated at room temperature for 2 weeks. Use gas chromatography (flame ion detector (FID), GasPro separation column) to monitor its methane production situation. When the methane concentration is not lower than 0.2mmol / L, it shows that the system is in strict anaerobic conditions, and the anaerobic reduction potential≦-200mV, At this time, 1 mmol / L trichlorethylene was added as the electron acceptor of the dehalogenated bacteria, and the enriched material of the dehalogenated bacteria was inoculated...

Embodiment 2

[0059] The method of this embodiment is the same as that of Embodiment 1, the difference is that the anaerobic dehalogenation bacteria are cultivated with the halogenated organic compound cis-dichloroethylene as the single variable. The result is as Figure 4 As shown, after 51 days of cultivation, cis-dichloroethylene was completely dechlorinated to form non-toxic ethylene. Also obtained the enriched anaerobic dehalogenating agent.

Embodiment 3

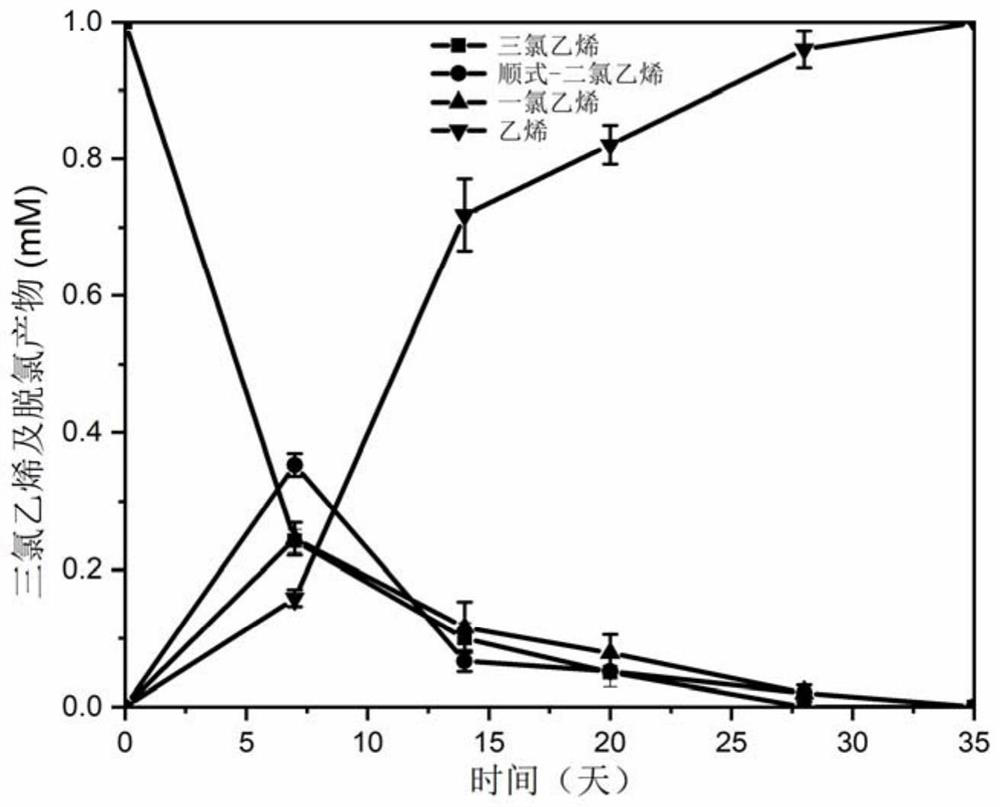

[0061] The method of this embodiment is the same as that of Embodiment 1, the difference is that the anaerobic dehalogenation bacteria are cultivated with the halogenated organic substance tetrachlorethylene as a single variable. The result is as Figure 5 As shown, after 35 days of cultivation, tetrachlorethylene was completely dechlorinated to form non-toxic ethylene. Also obtained the enriched anaerobic dehalogenating agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com