Composite carbon source additive and preparation method thereof

A composite carbon source and additive technology, which is applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

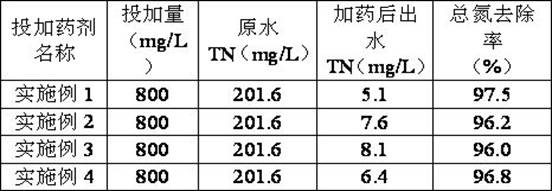

Embodiment 1

[0019] Composite carbon source additive by weight percentage, 15% 1,2-ethylene glycol (ethylene glycol), 15% methyl glycol, 30% sodium acetate, 15% propylene glycol methyl ether acetate, 15% protein High in peptides and amino acids, the balance is water. Among them, the mass ratio of protein high peptide and amino acid is 3:7, and both substances are purchased from Hailan Biology.

[0020] The preparation method of composite carbon source additive:

[0021] Obtain each raw material according to the above ratio, dissolve sodium acetate in water at room temperature to obtain an aqueous solution of sodium acetate, and then add 1,2-ethylene glycol, methyl ethylene glycol and propylene glycol methyl ether acetate to the aqueous solution of sodium acetate in sequence Stir to fully dissolve, then add protein high peptide and amino acid after fully dissolved, and after all dissolve, it will be a composite carbon source additive.

[0022] When the above raw materials are added into t...

Embodiment 2

[0024] Composite carbon source additive by weight percentage, 11% 1,2-ethylene glycol (ethylene glycol), 25% methyl glycol, 20% sodium acetate, 19% propylene glycol methyl ether acetate, 20% protein High in peptides and amino acids, the balance is water. Among them, the mass ratio of high protein peptides and amino acids is 3:7.

[0025] The preparation method of composite carbon source additive:

[0026] Obtain each raw material according to the above ratio, dissolve sodium acetate in water at room temperature to obtain an aqueous solution of sodium acetate, and then add 1,2-ethylene glycol, methyl ethylene glycol and propylene glycol methyl ether acetate to the aqueous solution of sodium acetate in sequence Stir to fully dissolve, then add protein high peptide and amino acid after fully dissolved, and after all dissolve, it will be a composite carbon source additive.

[0027] When the above raw materials are added into the sodium acetate aqueous solution, the various subst...

Embodiment 3

[0029] Composite carbon source additive by weight percentage, 12% 1,2-ethylene glycol (ethylene glycol), 13% methyl glycol, 15% sodium acetate, 15% propylene glycol methyl ether acetate, 15% protein High in peptides and amino acids, the balance is water. Among them, the mass ratio of protein high peptide to amino acid is 2:3.

[0030] The preparation method of composite carbon source additive:

[0031] Obtain each raw material according to the above ratio, dissolve sodium acetate in water at room temperature to obtain an aqueous solution of sodium acetate, and then add 1,2-ethylene glycol, methyl ethylene glycol and propylene glycol methyl ether acetate to the aqueous solution of sodium acetate in sequence Stir to fully dissolve, then add protein high peptide and amino acid after fully dissolved, and after all dissolve, it will be a composite carbon source additive.

[0032] When the above raw materials are added into the sodium acetate aqueous solution, the various substanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com