Trifluoromethyl allyl compound as well as preparation method and application thereof

A technology of trifluoromethylpropenyl and methyl methacrylate, which is applied in the field of trifluoromethylpropenyl compounds and their preparation, and can solve by-product halogen salt/high-salt wastewater, cumbersome post-reaction treatment, and reaction conditions Harsh problems, such as excellent stereoselectivity, tolerance to broad-spectrum functional groups, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) In a 10mL Shrek tube, under argon atmosphere, add 0.2mmol 2-hydroxy (phenyl) methyl methacrylate, 0.3mmol sodium trifluoromethyl sulfinate, 0.008mmol 3,6,-di-tert- Butyl-9-mesityl-10-phenylacridine-10-tetrafluoroborate, add 3mL of acetonitrile, stir and react under argon, room temperature and 18W blue light irradiation, the reaction equation is:

[0028] (2) After TLC monitors that the reaction is complete, remove the solvent with a vacuum rotary evaporator, and separate the product by thin-layer chromatography. The developing agent is petroleum ether / ethyl acetate system, and the product is light yellow liquid (E)-2-benzylidene -4,4,4-trifluorobutyric acid methyl ester, yield 71%.

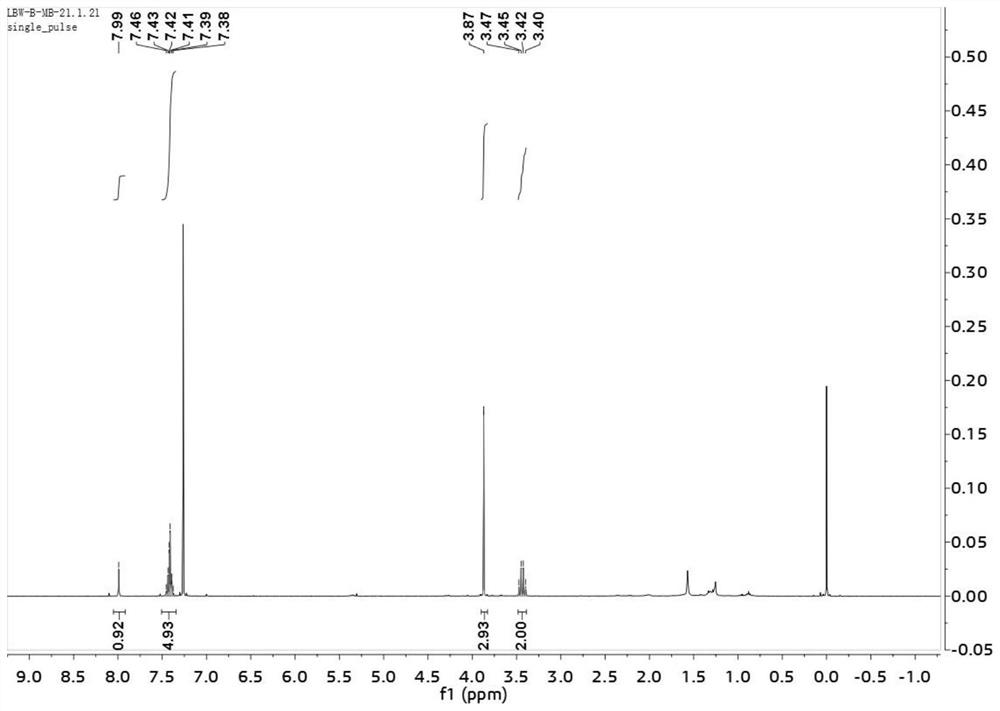

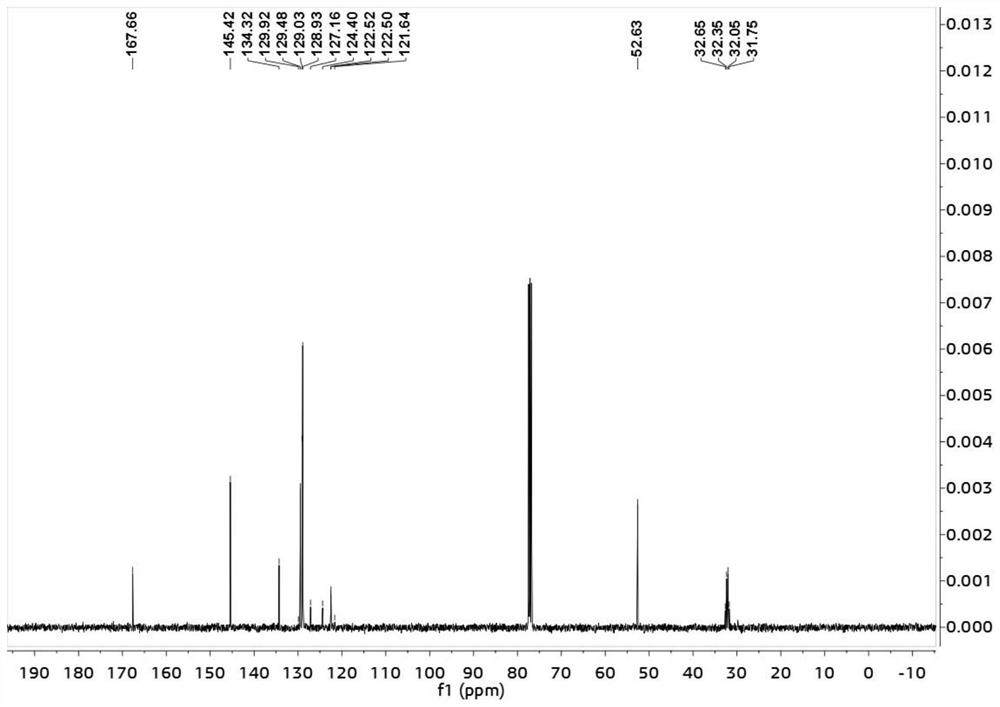

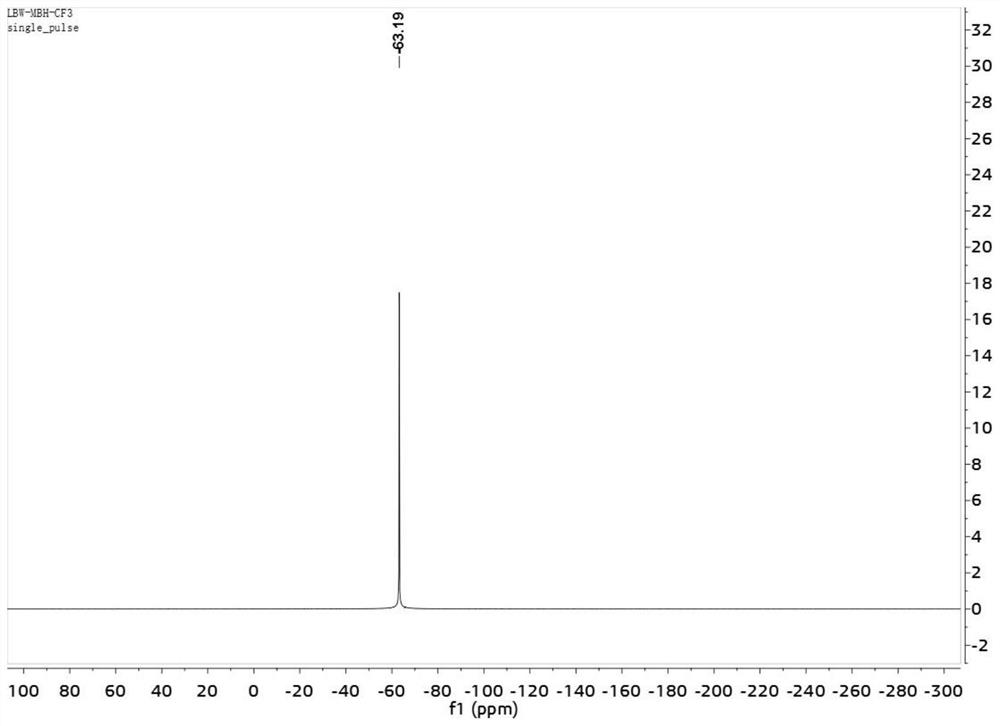

[0029] (E)-2-benzylidene-4,4,4-trifluorobutanoic acid methyl ester was subjected to NMR test, as Figure 1~3 as shown, figure 1 It is the H NMR spectrum of (E)-2-benzylidene-4,4,4-trifluorobutyric acid methyl ester; figure 2 It is the carbon nuclear magnetic resonance spectrum of ...

Embodiment 2

[0031] (1) In a 10mL Shrek tube, under argon atmosphere, add 0.4mmol 2-hydroxyl (2,4-dichlorophenyl)methylcyclohex-2-en-1-one, 0.6mmol trifluoromethyl Sodium sulfinate, 0.016mmol 3,6,-di-tert-butyl-9-mesityl-10-phenylacridine-10-tetrafluoroborate, add 6mL acetonitrile, under argon, room temperature and 18W blue light Stirring reaction under irradiation, the reaction equation is:

[0032]

[0033] (2) After TLC monitors that the reaction is complete, remove the solvent with a vacuum rotary evaporator, and separate the product by thin-layer chromatography. The developer is a sherwood oil / ethyl acetate system, and the product is a light yellow liquid (E)-2-(2, 4-dichlorobenzylidene)-3-(trifluoromethyl)cyclohexan-1-one, yield 74%.

Embodiment 3

[0035] This embodiment is basically the same as the above-mentioned Example 1, except that 10 mmol 2-hydroxy (phenyl) methyl methacrylate, 15 mmol sodium trifluoromethyl sulfinate, 0.4 mmol 3 ,6,-di-tert-butyl-9-mesityl-10-phenylacridine-10-tetrafluoroborate, add 150mL of acetonitrile, stir the reaction under argon, room temperature and 18W blue light irradiation to obtain ( E) 1.76 g of methyl 2-benzylidene-4,4,4-trifluorobutyrate, yield 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com