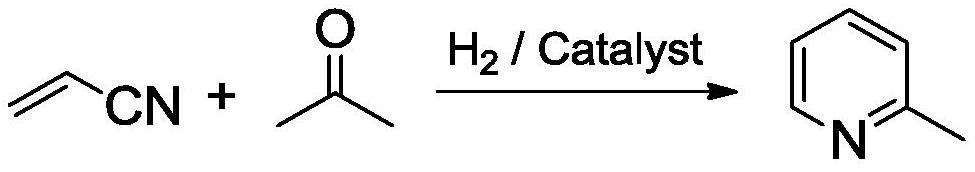

Catalyst for preparing 2-methylpyridine, preparation method and method for preparing 2-methylpyridine by using catalyst

A methylpyridine and catalyst technology, applied in the field of preparing 2-methylpyridine, can solve the problems of high cost of raw materials or catalysts, low selectivity of target products, difficulty in product separation and purification, etc., and achieves long service life, high selectivity, Simple effect of product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] On the other hand, the preparation method of the supported palladium catalyst for preparing 2-picoline, comprises the steps:

[0034] i) One or more of praseodymium oxide powder, neodymium oxide powder, erbium oxide powder and ytterbium oxide powder is made into a slurry, then shaped and granulated, and fired at 400-500°C for 4-6 hours to obtain the formed Carrier;

[0035] ii) The active component precursor (any one of palladium dichlorotetraammine, palladium dichloride, palladium acetate and ammonium tetrachloropalladate) is dissolved in water to form a solution, and the auxiliary agent precursor (trichloro One or more of indium, rhenium trichloride and osmium trichloride) to prepare an impregnation solution; place the obtained molded carrier in the impregnation solution and stir evenly, and then stir at 60-100°C until all the water evaporates;

[0036] iii) drying the support obtained in step ii) by drying at 100-120° C. for 4-6 hours, and then calcining at 400-500...

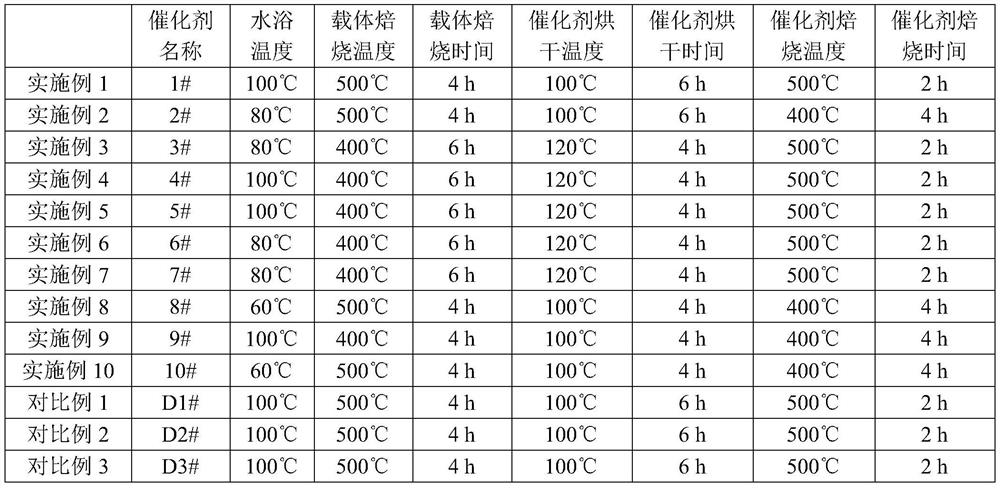

Embodiment 1~10

[0067] Embodiment 1~10 and its comparative example 1-3

[0068] The spherical carrier is prepared by a method well known to those skilled in the art. The specific process is as follows: add one or more of praseodymium oxide, neodymium oxide, erbium oxide and ytterbium oxide powder into water, stir evenly to form a carrier slurry, and then shape Granulate, and finally bake at 400-500°C for 4-6 hours to obtain a particle size range of 2-5mm and a BET specific surface area range of 50-150m 2 / g spherical carrier. In Comparative Examples 2 to 3, the carrier is a commercial carrier, which does not need to be molded, and the active components and additives can be directly impregnated and loaded.

[0069] Adopt impregnation method to prepare described loaded palladium catalyst, specific process is as follows: Active component (dichloro tetraammine palladium, tetrachloro palladium ammonium, palladium acetate or palladium dichloride) and optional auxiliary agent (for example, three O...

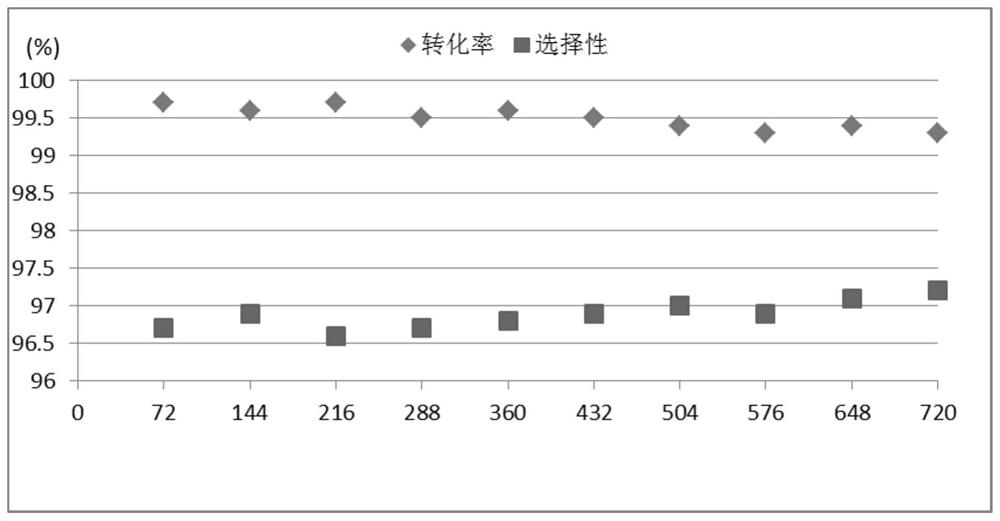

Embodiment 11~23 and comparative example 4~6

[0079] Select 13 catalysts from 1# to 10# and D1# to D3# for screening. The method is: use a fixed-bed reactor from top to bottom to investigate the reaction performance of the catalyst. The fixed-bed reactor is a stainless steel with an inner diameter of 4cm and a length of 80cm. Tube. The catalyst loading was 20 g and diluted to 100 mL with glass beads. Each catalyst was loaded into a fixed-bed reactor respectively, and each catalyst was activated under the protection of nitrogen, and activated at 400°C for 2 hours. Then cool to below 40°C and stop nitrogen purging. Mix acrylonitrile and acetone according to a certain mass ratio and pass through the catalyst bed in liquid phase. Under the condition of continuously feeding hydrogen, adjust the fixed bed reactor to the temperature required for the reaction, and adjust the hydrogen pressure to maintain suitable reaction conditions. After 20 hours of stable reaction, the composition of the reaction solution was analyzed by gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com