Preparation and application of a polyacrylate dispersant and superhydrophobic coating

A polyacrylate and acrylate technology, applied in coatings and other directions, can solve the problems of difficulty in obtaining transparency and durability of super-hydrophobic coatings, less dispersants in super-hydrophobic nano-composite coatings, etc., and achieve good super-hydrophobicity. Cleaning performance, uniform morphology, and strong general-purpose substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of transparent superhydrophobic coating of the present invention comprises the following steps:

[0055] Step S1, preparing polyacrylate dispersant, including two preparation methods:

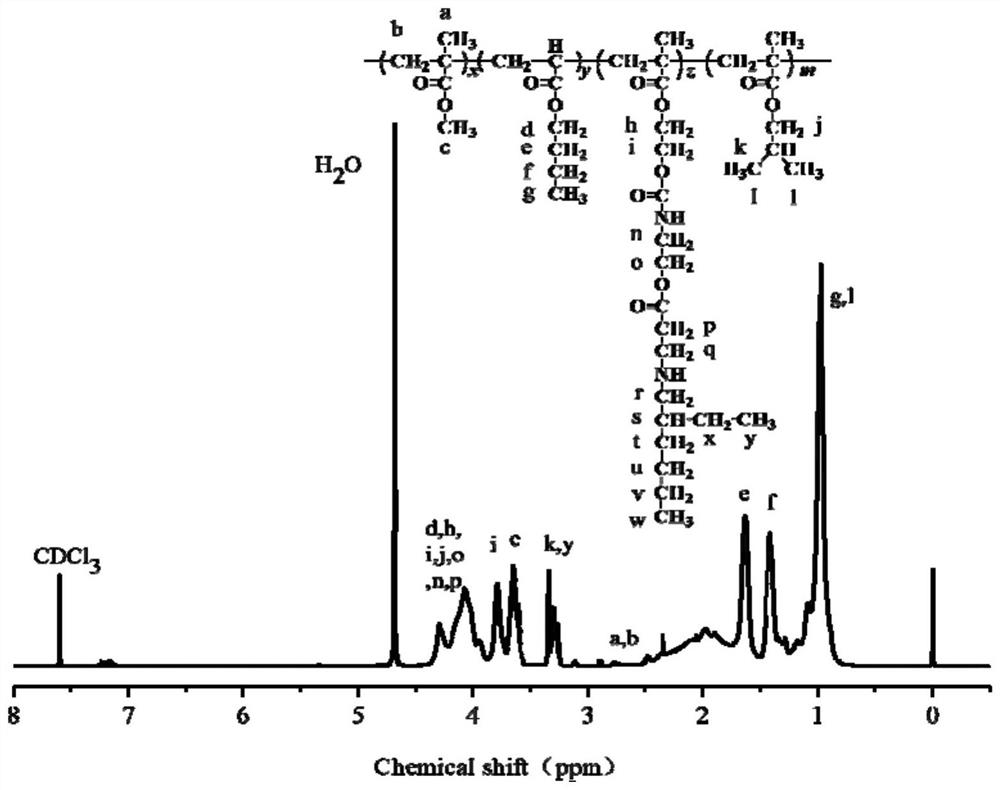

[0056] The first method: free radical polymerization of four (amino) acrylate monomers:

[0057] A1: According to the molar percentage (25~30): (10~15): (45~55): (5~15) the (meth)acrylate monomer containing amino structure and the other three (meth) ) acrylate monomers (methyl methacrylate, butyl acrylate and isobutyl methacrylate) dissolved in solvents (methanol, ethanol, xylene, propylene glycol methyl ether acetate, tetrahydrofuran, N,N-dimethylformaldehyde Amide or one or more of them mixed with butyl acetate), the mass percentage of methacrylate monomer containing amino structure and the remaining three (meth)acrylate monomers and solvent (same as above) For (8~20): (80~92), obtain the monomer mixture;

[0058] B1: According to the initiator (azobisisobutyr...

Embodiment 1

[0082] A polyacrylate dispersant (1) was prepared by free radical polymerization of four (amino) acrylate monomers:

[0083] a. Preparation of (meth)acrylate monomer containing amino structure:

[0084]Dissolve HEMA monomer and IEA monomer in solvent methanol and ethanol mixture respectively to obtain 10% mass percentage concentration of IEA solution and HEMA solution monomer solution; The precursor solution is added dropwise to the HEMA monomer solution, and the precursor solution is obtained after continuous reaction and purification; the obtained precursor solution and the amine monomer 2-ethylhexylamine (EAm) are dissolved in the solvent methanol and ethanol mixture respectively , to obtain a precursor monomer solution and an amine monomer solution with a mass percent concentration of 8% respectively; under nitrogen, add the amine monomer solution dropwise to the precursor monomer solution at a molar percentage of 40:60, and continue After reaction and purification, the m...

Embodiment 2

[0090] The polyacrylate dispersant (2) was prepared by free-radical polymerization of four (amino) acrylate monomers:

[0091] a. Preparation of (meth)acrylate monomer containing amino structure:

[0092] Dissolve the HEMA monomer and the IEA monomer in the solvent xylene respectively to obtain a mass percent concentration of 8% IEA solution and a HEMA solution monomer solution; Add dropwise in the HEMA monomer solution, continue the reaction, and obtain the precursor solution after purification; the obtained precursor solution and the amine monomer oleylamine (OAm) are respectively dissolved in the solvent xylene, and the mass percent concentration is 20% respectively. Precursor monomer solution and amine monomer solution; under nitrogen conditions, add the amine monomer solution dropwise to the precursor monomer solution according to the molar percentage of 30:70, continue the reaction, and obtain the amine-containing structure after purification Methacrylate monomer (2). ...

PUM

| Property | Measurement | Unit |

|---|---|---|

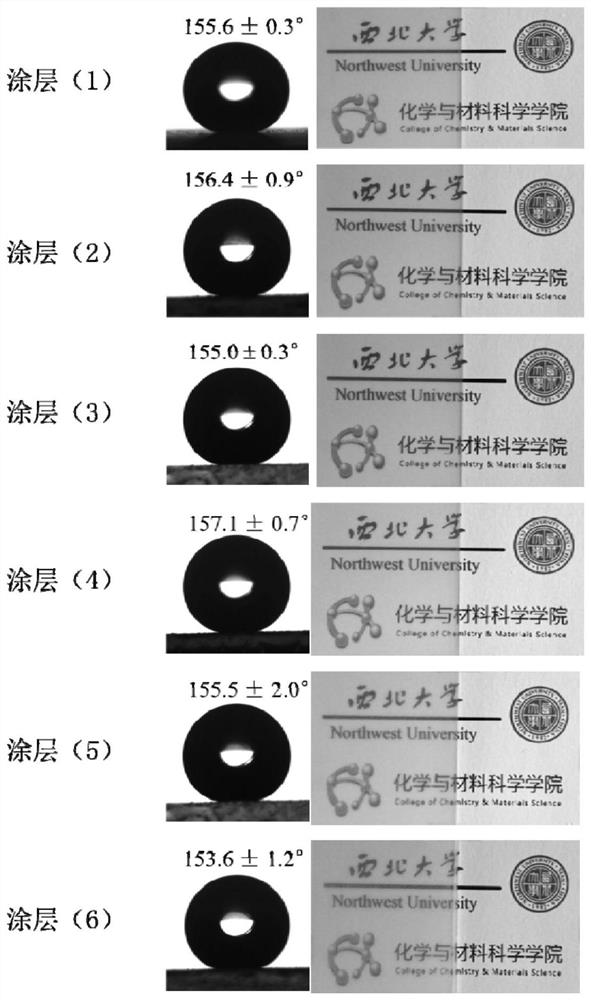

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com