Ternary material, preparation method and battery

A technology of ternary materials and modified elements, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of deteriorating electrochemical properties of materials, breaking, and difficult processes, so as to improve electrochemical properties and suppress microcracks And the effect of breaking and optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

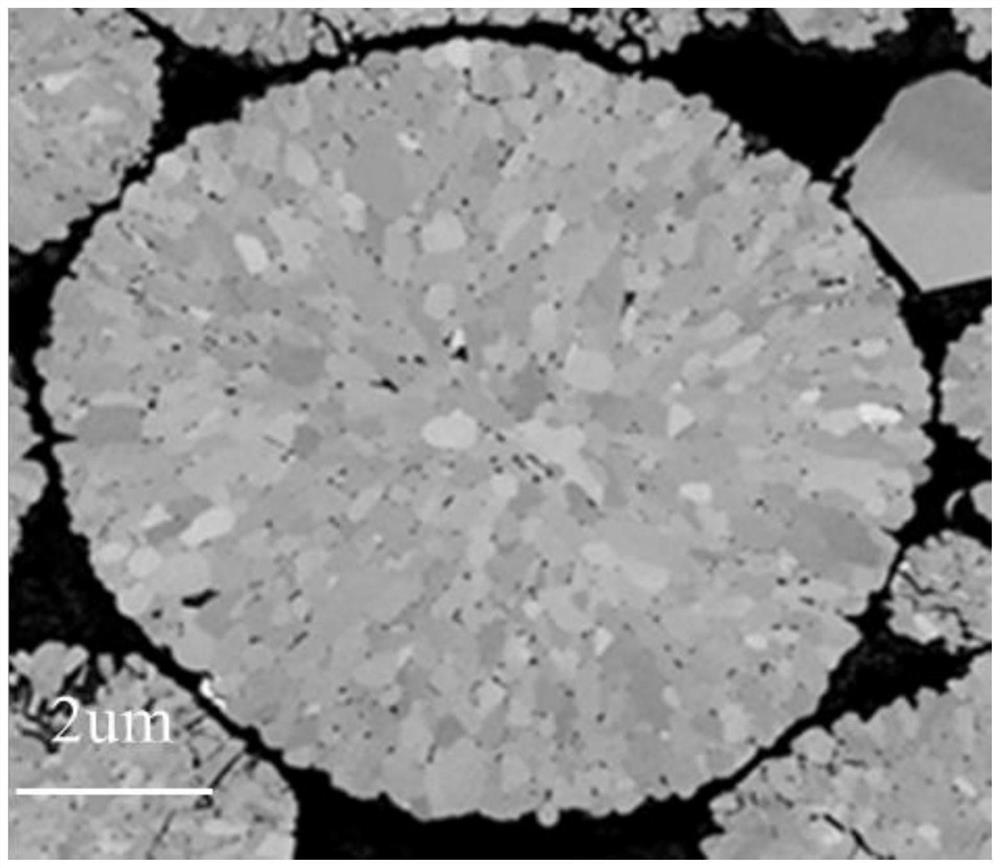

Embodiment 1

[0056] This embodiment provides a nickel-cobalt-manganese ternary positive electrode material with a coating layer, including a ternary positive electrode material and a coating layer covering the surface of the ternary positive electrode material. The general chemical formula of the ternary positive electrode material is Li(Ni 0.8 co 0.1 mn 0.1 ) 0.95 W 0.05 o 2 , the material of the cladding layer is aluminum oxide and boron oxide.

[0057] This embodiment also provides a preparation method of the above-mentioned ternary positive electrode material, and the preparation method specifically includes the following steps:

[0058] (1) Nickel sulfate, cobalt sulfate and manganese sulfate are mixed into the mixed salt solution that concentration is 4mol / L by stoichiometric ratio, meanwhile, the sodium hydroxide solution of preparation 4mol / L and the ammoniacal solution of 10wt%; Mixed salt solution , sodium hydroxide solution and ammonia solution are simultaneously added to t...

Embodiment 2

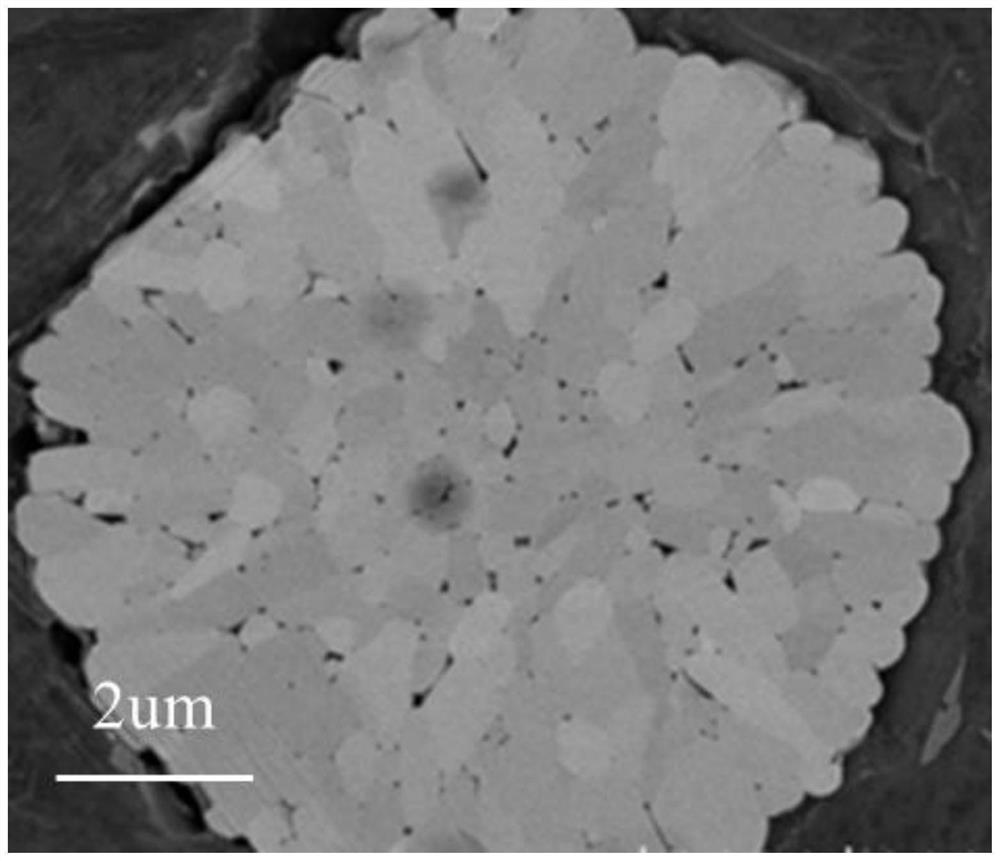

[0063] This embodiment provides a nickel-cobalt-manganese ternary positive electrode material with a coating layer, including a ternary positive electrode material and a coating layer covering the surface of the ternary positive electrode material. The general chemical formula of the ternary positive electrode material is Li(Ni 0.75 co 0.15 mn 0.1 ) 0.9 B 0.1 o 2 , the material of the cladding layer is titanium oxide.

[0064] This embodiment also provides a preparation method of the above-mentioned ternary positive electrode material, and the preparation method specifically includes the following steps:

[0065] (1) nickel chloride, cobalt chloride and manganese chloride are mixed with the mixed salt solution that concentration is 1mol / L by stoichiometric ratio, meanwhile, prepare the sodium hydroxide solution of 2mol / L and the ammonia solution of 5wt%; Mixed salt solution, sodium hydroxide solution and ammonia solution are added to the mixer at the same time according t...

Embodiment 3

[0070] This embodiment provides a nickel-cobalt-manganese ternary positive electrode material with a coating layer, including a ternary positive electrode material and a coating layer covering the surface of the ternary positive electrode material. The general chemical formula of the ternary positive electrode material is Li(Ni 0.78 co 0.1 mn 0.12 ) 0.92 Tl 0.08 o 2 , the material of the cladding layer is zirconia.

[0071] This embodiment also provides a preparation method of the above-mentioned ternary positive electrode material, and the preparation method specifically includes the following steps:

[0072] (1) Nickel nitrate, cobalt nitrate and manganese nitrate are mixed into the mixed salt solution that concentration is 1.5mol / L by stoichiometric ratio, meanwhile, the sodium hydroxide solution of preparation 3mol / L and the ammonia solution of 8wt%; Mixed salt Solution, sodium hydroxide solution and ammonia solution were added to the mixer at the same time according ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com