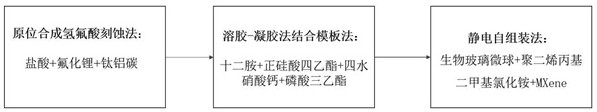

A kind of preparation method of high biological activity mxene/biological glass microsphere composite material

A bio-glass and bio-active technology, which is applied in the fields of pharmaceutical formulation, tissue regeneration, drug delivery, etc., can solve unseen problems, achieve the effects of promoting precipitation, increasing deposition, and broad industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of highly bioactive MXene / biological glass microsphere composite material, comprising the following steps:

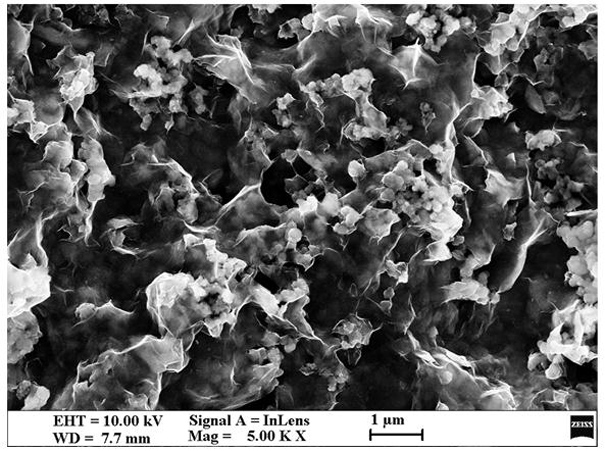

[0035](1) Prepare MXene by in-situ synthetic hydrofluoric acid etching method: take 20 ml of 6M HCl and place it in a polytetrafluoroethylene beaker, then add 500 mg of LiF, wait until LiF is completely dissolved, and weigh 500 mg of Ti 3 AlC 2 The powder was slowly added into the solution, and the stirring was continued for 24 h. The supernatant was sonicated for 1 h, and then centrifuged at 3500 r / min for 1 h. The supernatant was collected and freeze-dried for 24 h to obtain MXene (Ti 3 C 2 )powder.

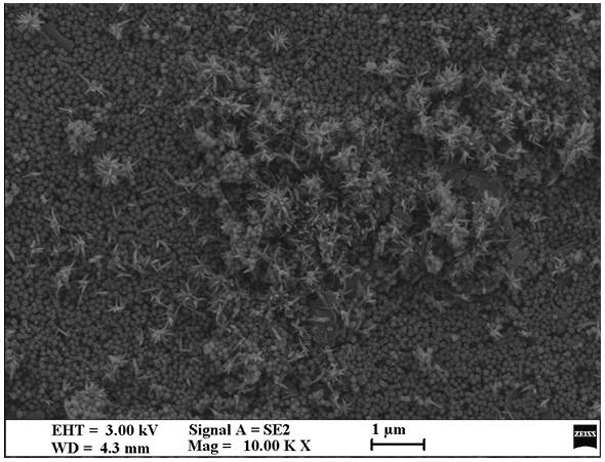

[0036] (2) Bioglass microspheres were prepared by the sol-gel method combined with the template method: first, 1.1057 g of dodecylamine was weighed as a template agent, poured into an ethanol solution with a concentration of 24 wt%, and tetraethyl orthosilicate was selected , calcium nitrate tetrahydrate, and triethyl phosphate were used as...

Embodiment 2

[0046] A preparation method of highly bioactive MXene / biological glass microsphere composite material, comprising the following steps:

[0047] (1) Prepare MXene by in-situ synthetic hydrofluoric acid etching method: take 20 ml of 6M HCl and place it in a polytetrafluoroethylene beaker, then add 500 mg of LiF, wait until LiF is completely dissolved, and weigh 500 mg of Ti 3 AlC 2 The powder was slowly added into the solution, and the stirring was continued for 24 h. The supernatant was sonicated for 1 h, and then centrifuged at 3500 r / min for 1 h. The supernatant was collected and freeze-dried for 24 h to obtain MXene (Ti 3 C 2 )powder.

[0048] (2) Bioglass microspheres were prepared by the sol-gel method combined with the template method: first, 1.1057 g of dodecylamine was weighed as a template agent, poured into an ethanol solution with a concentration of 24 wt%, and tetraethyl orthosilicate was selected , calcium nitrate tetrahydrate, and triethyl phosphate were used a...

Embodiment 3

[0058] A preparation method of highly bioactive MXene / biological glass microsphere composite material, comprising the following steps:

[0059] (1) Prepare MXene by in-situ synthetic hydrofluoric acid etching method: take 20 ml of 6M HCl and place it in a polytetrafluoroethylene beaker, then add 500 mg of LiF, wait until LiF is completely dissolved, and weigh 500 mg of Ti 3 AlC 2 The powder was slowly added into the solution, and the stirring was continued for 24 h. The supernatant was sonicated for 1 h, and then centrifuged at 3500 r / min for 1 h. The supernatant was collected and freeze-dried for 24 h to obtain MXene powder.

[0060] (2) Bioglass microspheres were prepared by the sol-gel method combined with the template method: first, 1.1057 g of dodecylamine was weighed as a template agent, poured into an ethanol solution with a concentration of 24 wt%, and tetraethyl orthosilicate was selected , calcium nitrate tetrahydrate, and triethyl phosphate were used as silicon sou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com