Preparation method of low-crystallinity zirconium-doped ferrocobalt layered double hydroxide and application of low-crystallinity zirconium-doped ferrocobalt layered double hydroxide in water electrolysis for hydrogen production

A technology with low crystallinity and hydroxide, which is applied in the direction of electrolysis process, electrolysis components, electrolysis inorganic material coating, etc., can solve the problems of poor stability, high price, and limitation of large-scale application, and achieve mild reaction, low price, The effect of the simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation of a low-crystallinity material of zirconium-doped cobalt-iron layered double hydroxide comprises the following steps:

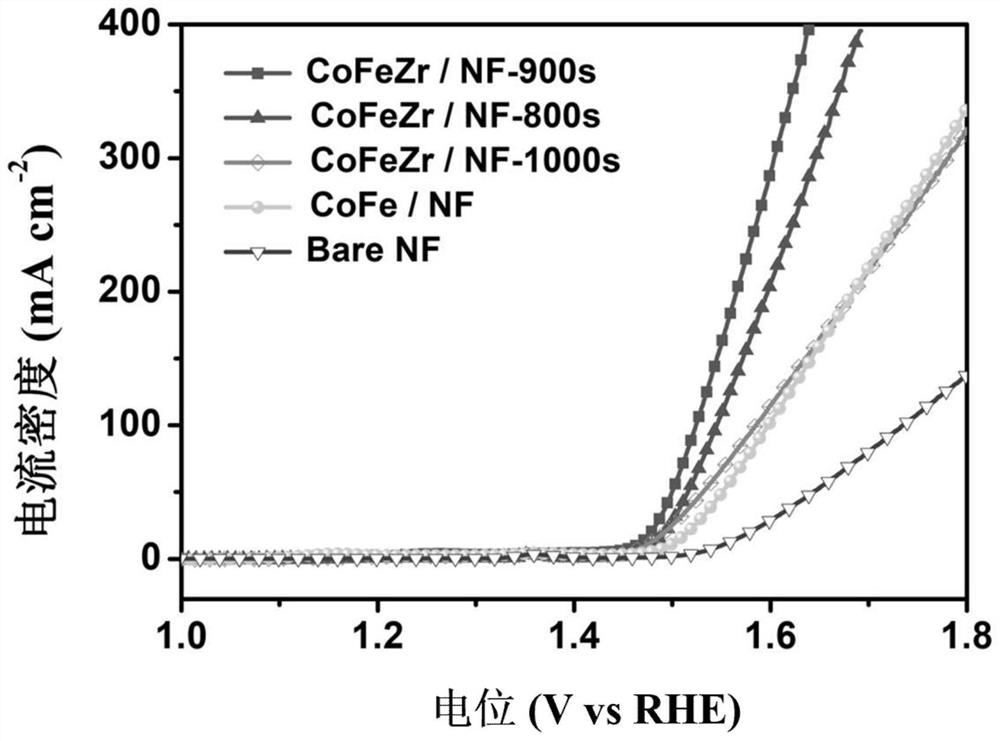

[0027] will contain 2mM Co(NO 3 ) 2 ·6H 2 O(0.582g), 2mM Fe(NO 3 ) 3 9H 2 O (0.808g), 2mM ZrCl 4 (0.466g), 0.3M KNO 3 (3.03 g) was dissolved in 100 mL of deionized water and stirred at a constant speed for 1 hour to form a homogeneous solution; the substrate NF was placed in nitric acid to clean the surface impurities and remove oxides; CoFeZr / Electrodeposition of NF-900s, Pt electrode, Ag / AgCl electrode and NF are used as counter electrode, reference electrode and working electrode respectively. The specific experimental process uses a constant voltage of -1.1V (vs Ag / AgCl electrode) for 900s Electrodeposition. In addition, the electrodeposited material has an area of 1 cm 2 ; The prepared material was washed twice with deionized water and ethanol, respectively, and dried under vacuum at 60° C. for 2 h.

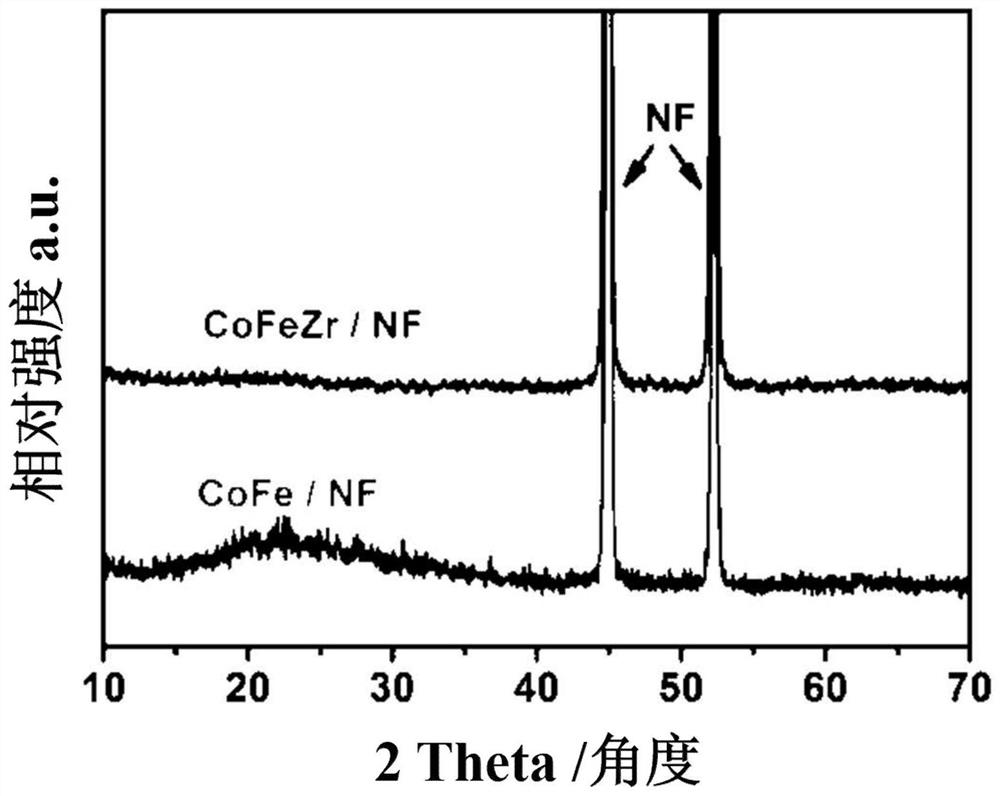

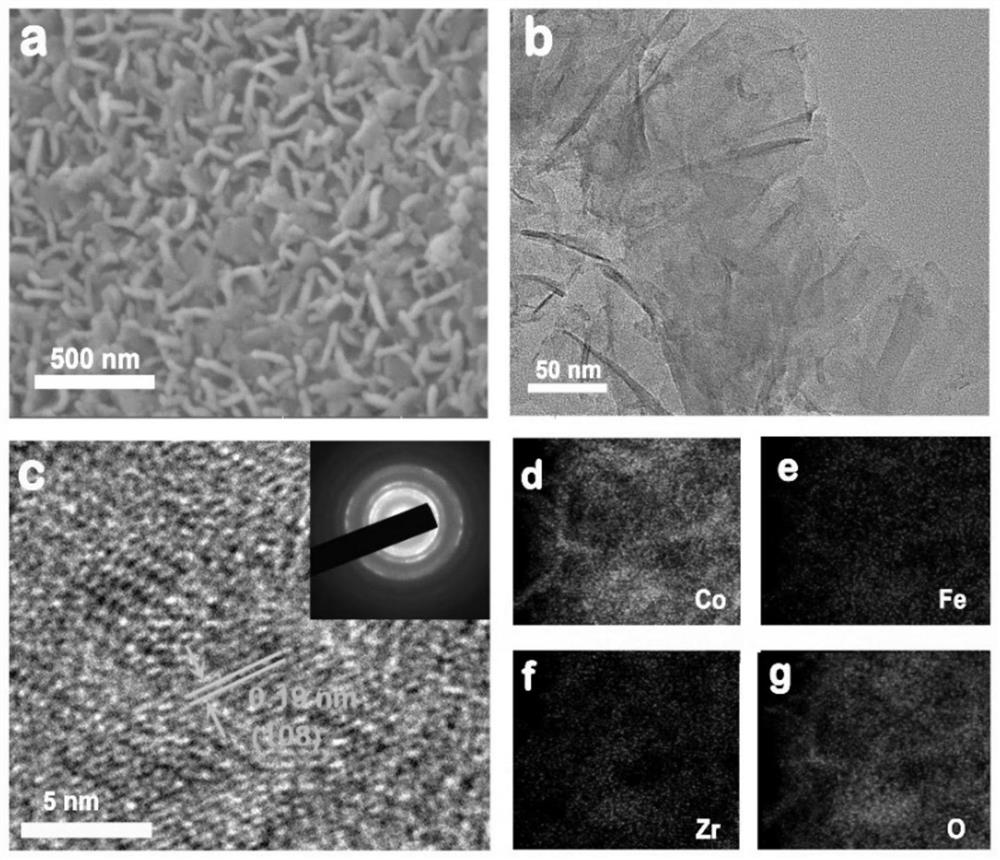

[0028] figure 1...

Embodiment 2

[0031] The preparation of a low-crystallinity material of zirconium-doped cobalt-iron layered double hydroxide comprises the following steps:

[0032] will contain 2mM Co(NO 3 ) 2 ·6H 2 O(0.582g), 2mM Fe(NO 3 ) 3 9H 2 O (0.808g), 2mM ZrCl 4 (0.466g), 0.3M KNO 3 (3.03 g) was dissolved in 100 mL of deionized water and stirred at a constant speed for 1 hour to form a homogeneous solution. Subsequently, the substrate NF was put into nitric acid to clean the surface impurities and remove oxides. Then, electrodeposition of CoFeZr / NF-800s was performed by a three-electrode system in the above solution. Pt electrode, Ag / AgCl electrode, and NF were used as auxiliary, reference, and working electrodes, respectively. During the experiment, a constant voltage of -1.1V (vs Ag / AgCl electrode) was used for electrodeposition for 800s. In addition, the electrodeposited material has an area of 1 cm 2 . Finally, the as-prepared material was washed twice with deionized water and eth...

Embodiment 3

[0035] The preparation of a low-crystallinity material of zirconium-doped cobalt-iron layered double hydroxide comprises the following steps:

[0036] will contain 2mM Co(NO 3 ) 2 ·6H 2 O(0.582g), 2mM Fe(NO 3 ) 3 9H 2 O (0.808g), 2mM ZrCl 4 (0.466g), 0.3M KNO 3 (3.03 g) was dissolved in 100 mL of deionized water and stirred at a constant speed for 1 hour to form a homogeneous solution. Subsequently, the substrate NF was put into nitric acid to clean the surface impurities and remove oxides. Then, electrodeposition of CoFeZr / NF-1000s was performed by a three-electrode system in the above solution. Pt electrode, Ag / AgCl electrode, and NF were used as auxiliary, reference, and working electrodes, respectively. During the experiment, a constant voltage of -1.1V (vs Ag / AgCl electrode) was used for electrodeposition for 1000 s. In addition, the electrodeposited material has an area of 1 cm 2 . Finally, the as-prepared material was washed twice with deionized water and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com