Wastewater zero discharge treatment system and process

A treatment system and zero-discharge technology, applied in water/sewage treatment, heating water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of large investment, high operating cost, and complex formulation of chemicals, and simplify the process flow , Eliminate foul smell, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

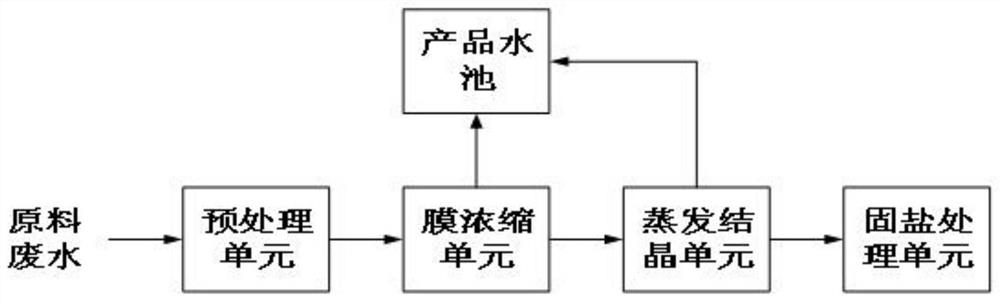

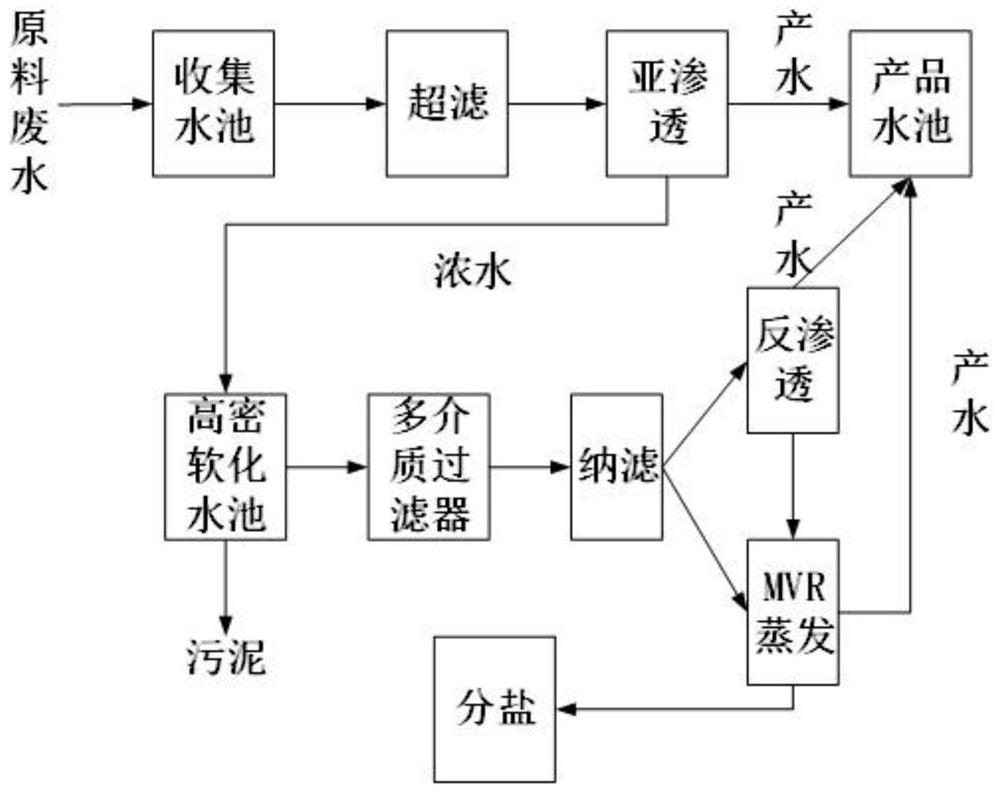

[0087] figure 1 It is a schematic structural diagram of a wastewater treatment zero discharge system according to Embodiment 1 of the present invention; figure 2 Schematic diagram of the zero-discharge process flow for wastewater treatment according to Embodiment 1.

[0088] Such as figure 1 As shown, the wastewater treatment zero discharge system includes a pretreatment unit, a membrane concentration unit, an evaporative crystallization unit, and a solid salt treatment unit for sequentially treating raw wastewater, as well as a water collection system for collecting the produced water from the membrane concentration unit and evaporative crystallization unit. The product pool; the pretreatment unit includes a collection pool and ultrafiltration equipment, and the membrane concentration unit includes the first reverse osmosis membrane equipment (sub-osmosis membrane equipment), high-density softening water tank, multi-media filter, nanofiltration equipment and second reverse ...

Embodiment approach 2

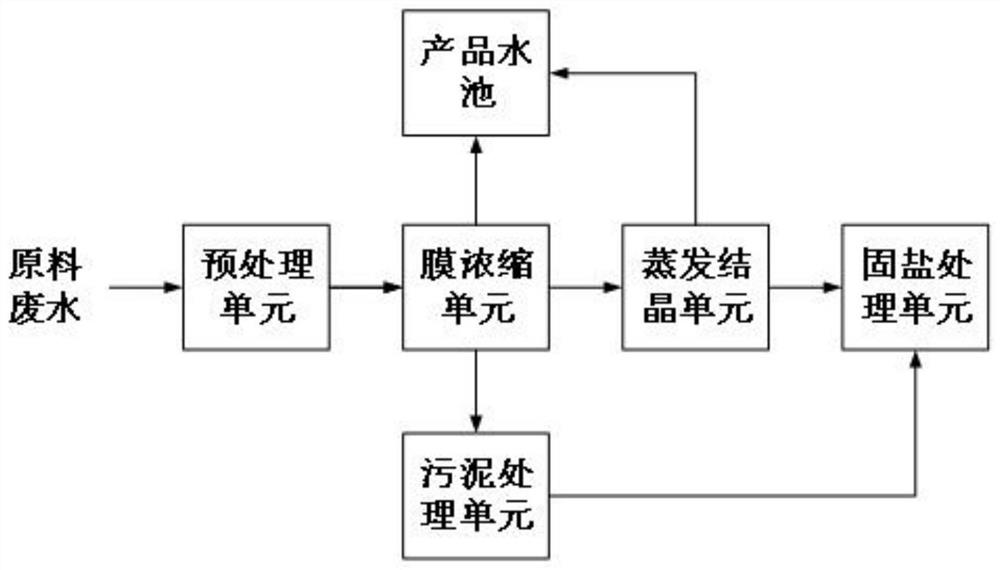

[0104] image 3 Schematic diagram of the structure of the wastewater treatment zero discharge system according to Embodiment 2; Figure 4 Schematic diagram of the zero-discharge process flow for wastewater treatment according to Embodiment 2. It is different from Embodiment 1 mainly in the following aspects:

[0105] Such as image 3 As shown, the wastewater zero discharge treatment system also includes a sludge treatment unit for collecting the sludge generated by the membrane concentration unit, and the sludge treatment unit includes a sludge tank and a sludge dehydration device.

[0106] In this embodiment, if Figure 4 As shown, the sludge treatment unit receives the sludge generated from the high-density softening tank of the membrane concentration unit, and processes the sludge. In this embodiment, the sludge dehydration equipment concentrates the sludge and prepares it as an auxiliary material for building materials , the control conditions for concentration of slud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com