Microcapsule preparation rich in astaxanthin as well as preparation method and application of microcapsule preparation

An astaxanthin and microcapsule technology, applied in microcapsules, skin care preparations, medical preparations containing active ingredients, etc., can solve the problems of astaxanthin deterioration, low astaxanthin content, etc. The effect of increasing the content, increasing the content and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] At present, the preparation of most deep eutectic solvents adopts the heating preparation method. The heating preparation method refers to mixing hydrogen bond acceptors and hydrogen bond donors in a specific molar ratio at room temperature or at a certain high temperature (50-100 ° C) until A homogeneous clear liquid was formed. Astaxanthin, as a fat-soluble functional component, has low solubility in commonly used organic solvents, but experiments have found that it has higher solubility in the deep eutectic solvent constructed by the present invention.

[0051] A kind of astaxanthin-rich microcapsule preparation proposed by the present invention comprises a wall material and a core material, wherein: the core material comprises astaxanthin and a deep eutectic solvent; and the astaxanthin is molecularly dissolved in In the deep eutectic solvent system; the wall material contains one or more of polysaccharide and protein. Wherein, the mass percent content of the astax...

Embodiment 1

[0092] At 80°C, mix thymol and lauric acid at a molar mass ratio of 2:1 and heat until clear and transparent, then cool and stand at room temperature to prepare a deep eutectic solvent.

[0093] Take 90 g of the above-mentioned deep eutectic solvent system, and heat and dissolve 10 g of astaxanthin in the deep eutectic solvent system at 90° C.

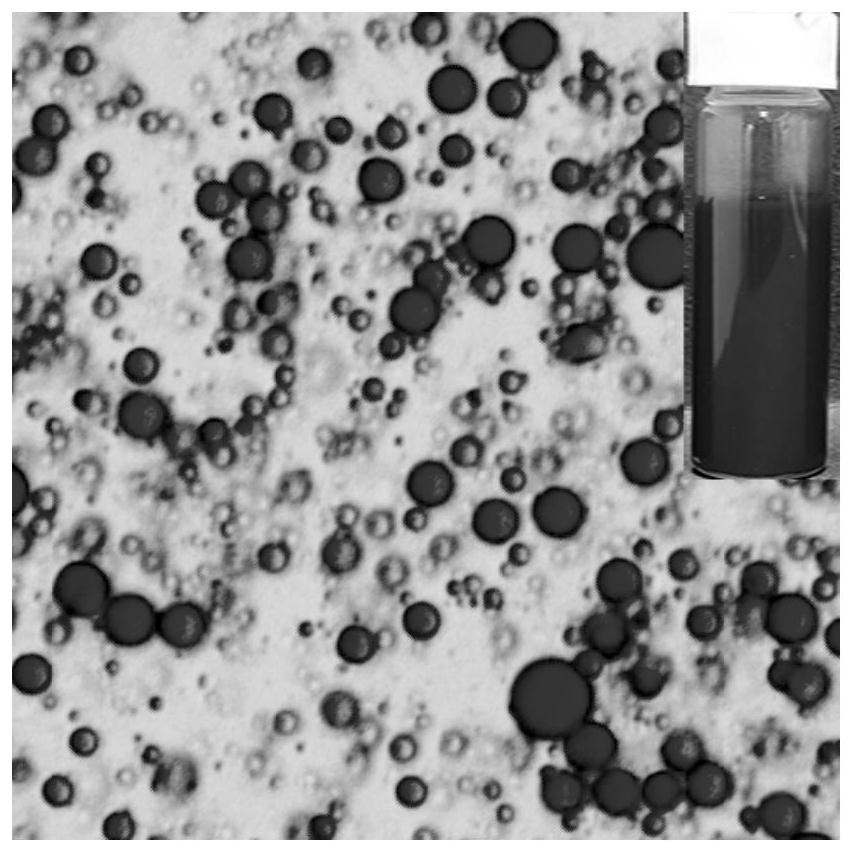

[0094] Take 30 g of the above-mentioned astaxanthin solution and disperse it in 70 g of water phase, wherein the components of the water phase are made of the following raw materials in parts by weight: 4 parts of soybean protein isolate, 2 parts of vitamin C, 1 part of ascorbic acid, and 1 part of gum arabic , 92 parts of deionized water. Blend the two phases of oil and water, and shear and disperse for 4 minutes at a shear speed of 16000 rpm in a high-speed shearing machine to prepare an oil-in-water Pickering emulsion.

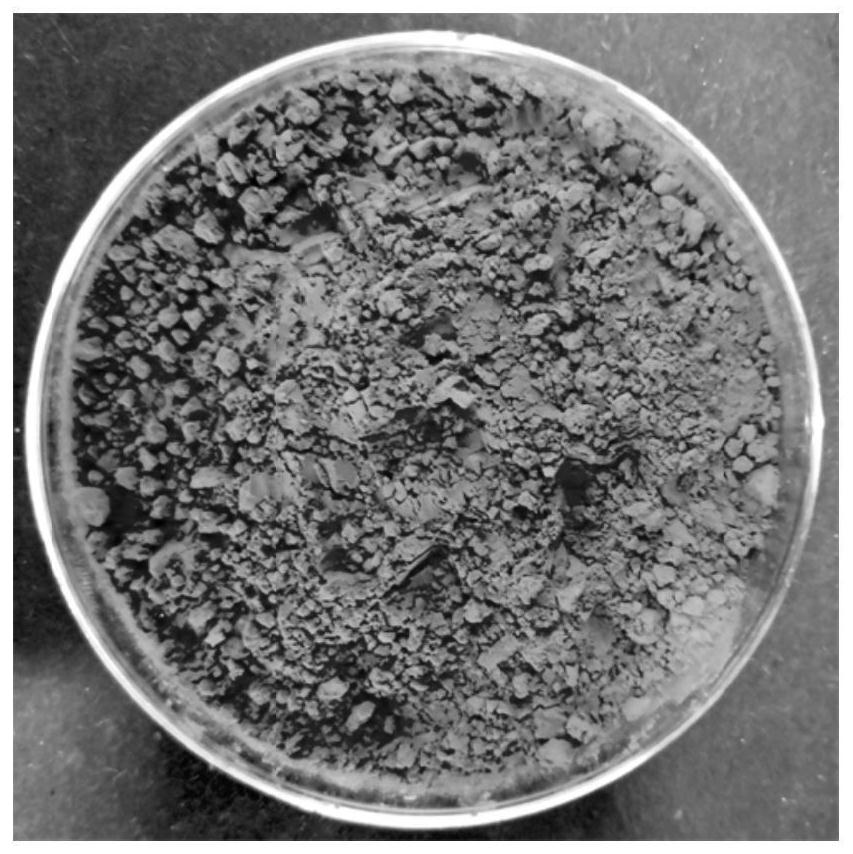

[0095] The prepared emulsion is spray-dried to obtain astaxanthin microcapsule powder. The spray-drying conditi...

Embodiment 2

[0098] At 80°C, mix thymol and lauric acid at a molar mass ratio of 3:1 and heat until clear and transparent, then cool and stand at room temperature to prepare a deep eutectic solvent.

[0099] 93.8 g of the above-mentioned deep eutectic solvent system was taken, and 6.2 g of astaxanthin was heated and dissolved in the deep eutectic solvent system at 80° C.

[0100] Take 10 g of the above-mentioned astaxanthin solution and disperse it in 90 g of water phase, wherein the components of the water phase are made of the following raw materials in parts by mass: 1.5 parts of whey protein isolate, 0.75 parts of cellulose polysaccharide, and 0.75 parts of microcrystalline starch , 0.8 parts of ascorbic acid, 2 parts of carrageenan, and 94.2 parts of deionized water. Blend the two phases of oil and water, and shear and disperse for 4 minutes at a shear speed of 16000 rpm in a high-speed shearing machine to prepare an oil-in-water Pickering emulsion.

[0101] The prepared emulsion is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com