Modified organic silicon composite material as well as preparation method and application thereof

A composite material and silicone technology, applied in the directions of adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of poor uniformity, limited temperature resistance, and low comprehensive performance, and achieve low dielectric, low Loss, the effect of high physical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

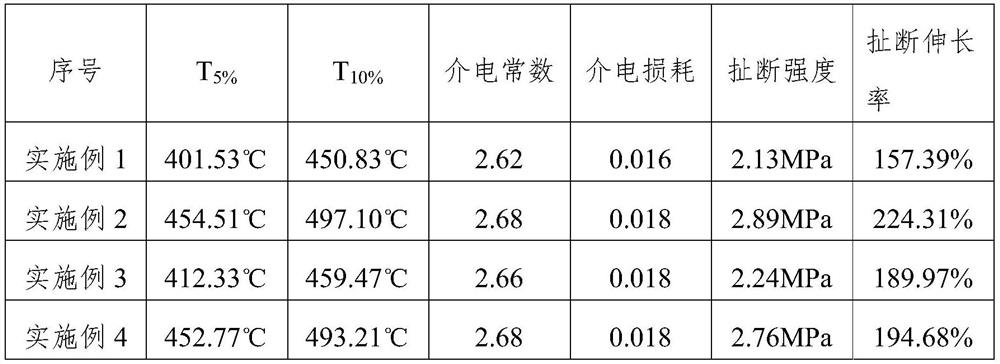

Examples

Embodiment 1

[0049] Weigh 55g of phenyl silicone rubber and 6g of fumed silica, mix and stir at room temperature for 1.5h, then add 50g of No. 120 solvent oil, 1.5g of ethyl orthosilicate, and 0.5g of dibutyltin dilaurate and stir for 3min; then Pour the composite slurry into the mold, vacuumize and defoam for 30 minutes; finally, place it at 25°C and 55% air moisture content for 168 hours to completely cure and form.

Embodiment 2

[0051] Weigh 6g of boron oxide, 3.4g of boron powder, and 2.2g of magnesium boride for pre-mixing, and then place them in a ball mill for 18 hours of ball milling at 300r / min to obtain a precursor. A ball with a diameter of 10mm contains 220g, and a ball with a diameter of 5mm contains 650g; then, the resulting precursor is placed in a horizontal tube furnace under 300sccm NH 3 Under the flow rate, high temperature sintering treatment at 1300°C for 6h to obtain crude boron nitride nanotubes; then, add the crude boron nitride nanotube powder into 33% concentration nitric acid solution, reflux at 140°C for 20h, and deionized water after cooling Wash with ethanol repeatedly to neutrality and dry to obtain pretreated boron nitride nanotubes; add 2.5g of pretreated boron nitride nanotubes to 0.4mol / L, volume of 500mL cerous nitrate ethanol solution and ultrasonic treatment for 45min, Then, 0.1 mol sodium hydroxide solution was added dropwise to pH = 10 during the stirring process, ...

Embodiment 3

[0053] Weigh 6g of boron oxide, 3.4g of boron powder, and 2.2g of magnesium boride for pre-mixing, and then place them in a ball mill for 300r / min ball milling for 18 hours to obtain the precursor. The grinding beads are zirconium balls, and the balls with a diameter of 15mm in the ball mill contain 150g. A ball with a diameter of 10mm contains 220g, and a ball with a diameter of 5mm contains 650g; then, the resulting precursor is placed in a horizontal tube furnace, 300sccm NH 3 1300°C for 6 hours at high temperature to obtain crude boron nitride nanotubes; then, add the obtained crude boron nitride nanotubes to a 33% nitric acid solution, reflux at 140°C, and rinse with deionized water and ethanol repeatedly until Neutralize and dry to obtain pretreated boron nitride nanotubes; add 1g of pretreated boron nitride nanotubes into 0.4mol / L, volume of 660mL cerous nitrate ethanol solution and ultrasonic treatment for 45min, then drop Add 0.1mol sodium hydroxide solution pH = 10, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com