Preparation method and application of biodegradable antioxidant fruit and vegetable preservative film

A fruit and vegetable preservation and biodegradation technology, applied in the field of biodegradable food film processing, can solve the problems of reducing the mechanical properties of the fresh-keeping film, low elongation at break, impact on human health, etc. The effect of high performance and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

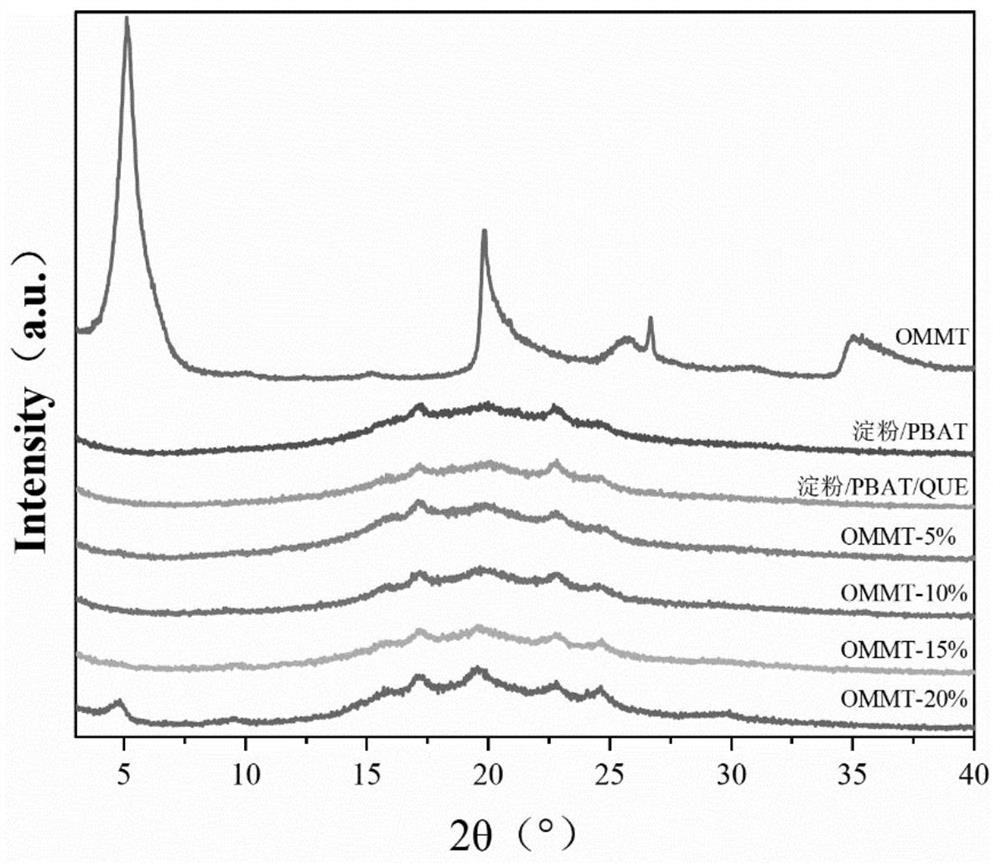

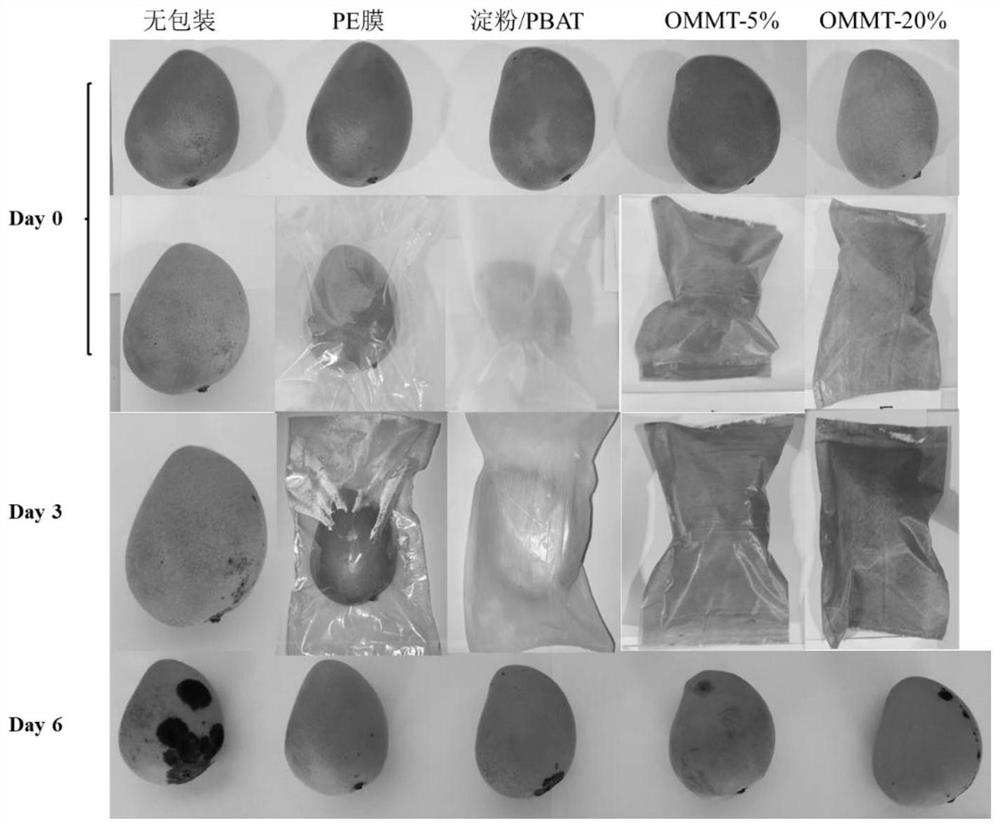

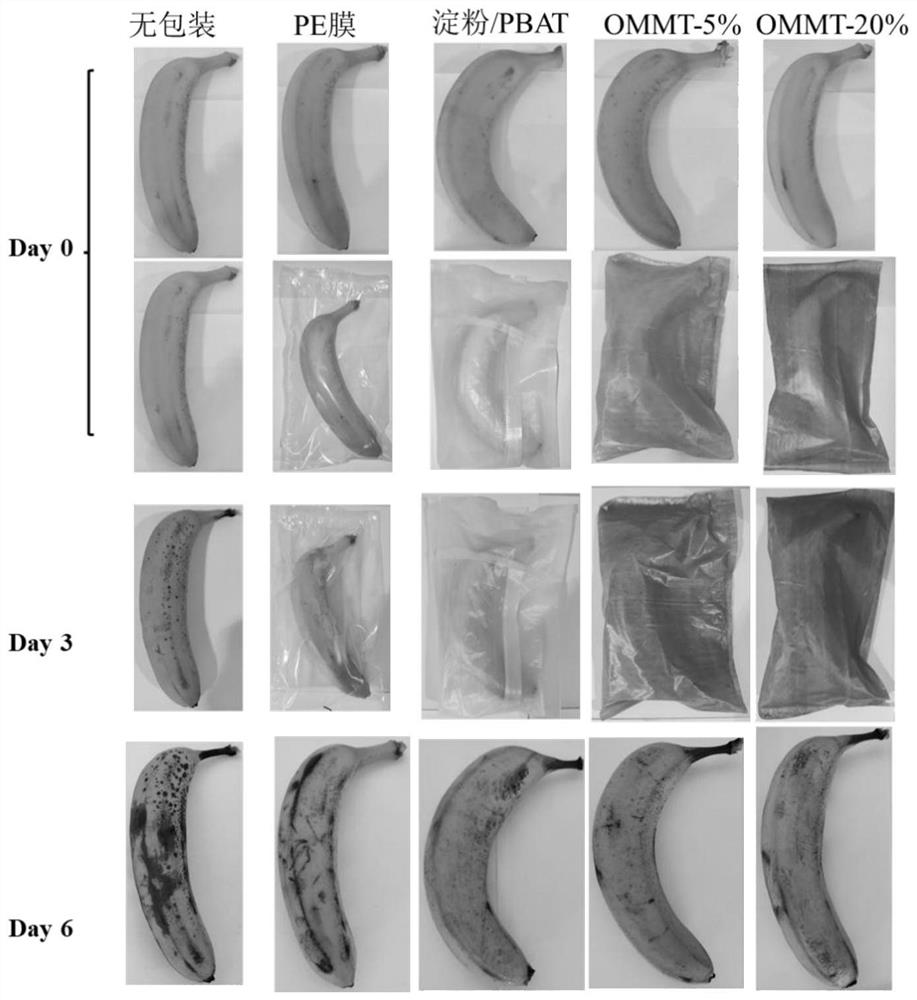

[0032] Weighed in parts by mass, put 100 parts of starch (St), 35 parts of glycerin, 5 parts of organically modified montmorillonite (OMMT) and 1 part of quercetin (QUE) into a high-speed mixer and mix for 5 minutes to obtain modified Powder; the modified powder and PBAT are mixed according to the mass ratio of 4:6, and then twin-screw melt extrusion granulation is carried out. The temperature from the feeding area to the head area of the twin-screw extruder is 110, 120, 130, 140, 120 and 100°C. Then extrude and blow at 140°C with a film blowing machine to obtain a biodegradable anti-oxidation fruit and vegetable fresh-keeping film, which is denoted as OMMT-5%.

Embodiment 2

[0034] Weighed in parts by mass, put 100 parts of starch (St), 35 parts of glycerin, 10 parts of organically modified montmorillonite (OMMT) and 1 part of quercetin (QUE) into a high-speed mixer and mixed for 5 minutes to obtain a modified Powder: The modified powder and PBAT are mixed according to the mass ratio of 4:6, and then twin-screw melt extrusion granulation is carried out. The temperature of each section of the twin-screw extruder is 140°C. Afterwards, a film blowing machine is used to extrude and blow at 110° C. to obtain a biodegradable anti-oxidation fruit and vegetable fresh-keeping film, which is recorded as OMMT-10%.

Embodiment 3

[0036] Weighed in parts by mass, put 100 parts of starch (St), 35 parts of glycerin, 15 parts of organically modified montmorillonite (OMMT) and 1 part of quercetin (QUE) into a high-speed mixer and mix for 5 minutes to obtain a modified Powder: The modified powder and PBAT are mixed according to the mass ratio of 4:6, and then twin-screw melt extrusion granulation is carried out. The temperature of each section of the twin-screw extruder is 120°C. Afterwards, a film blowing machine is used to extrude and blow at 120°C to obtain a biodegradable anti-oxidation fruit and vegetable fresh-keeping film, which is marked as OMMT-15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com