Flame-retardant waterborne polyurethane material

A water-based polyurethane, flame-retardant technology, applied in the field of polyurethane, can solve the problems of halogen harmful substances polluting the environment, poor compatibility between flame retardants and substrates, easy free coating surface, etc., to achieve good flame retardancy and self-dispersion The effect of improving compatibility, stability, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

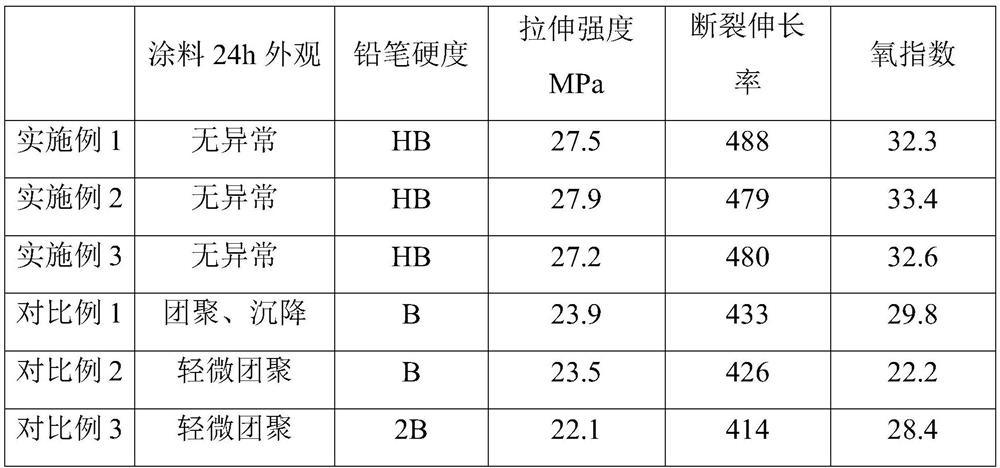

Examples

Embodiment 1

[0028] The polyurethane preparation process is as follows: 10% PEG-2000, 7% dimethylol propionic acid, 1% ethylene glycol chain extender and 1% N-methylpyrrolidone are added to the reaction flask, heated to 50 ° C and stirred 1h, then add 8-18% of 2,4-toluene diisocyanate, heat up to 80°C for 90 minutes; then add 4-5% polyethylene adipate propylene glycol ester diol, continue stirring for 60 minutes, cool After reaching below 50°C, add DMF to adjust the viscosity of the system, and finally add water to quickly emulsify to make the system solid content 30%.

[0029] Described composite flame retardant:

[0030] S1: Add the acidified attapulgite to ethanol for ultrasonic treatment, then add an equal mass of KH-570, stir and disperse evenly, then raise the temperature to 60-70°C, stir for 4-5h; centrifuge, wash with ethanol Collect solid and dry to obtain solid A;

[0031] S2: Add 0.1mol phenyl dichlorophosphate and 50ml acetone to the reaction flask, place the reaction flask i...

Embodiment 2

[0037] The polyurethane preparation process is as follows: 15% PEG-2000, 9% dimethylol propionic acid, 2% ethylene glycol chain extender and 3% N-methylpyrrolidone are added to the reaction bottle, heated to 50 ° C and stirred 1h, then add 10% 2,4-toluene diisocyanate, heat up to 80°C and react for 90min; then add 5% polyethylene adipate propylene glycol ester diol, continue stirring for 60min, cool to below 50°C Then add DMF to adjust the viscosity of the system, and finally add water to quickly emulsify to make the system solid content 35%.

[0038] Described composite flame retardant:

[0039] S1: Add the acidified attapulgite to ethanol for ultrasonic treatment, then add an equal mass of KH-570, stir and disperse evenly, then raise the temperature to 60-70°C, stir for 4-5h; centrifuge, wash with ethanol Collect the solid and dry it to obtain solid A; put 0.5g of the collected solid A into the reaction flask, add 0.1g of ammonium persulfate, 0.05g of sodium bisulfite and w...

Embodiment 3

[0044] The polyurethane preparation process is as follows: 15% PEG-2000, 9% dimethylol propionic acid, 2% ethylene glycol chain extender and 3% N-methylpyrrolidone are added to the reaction bottle, heated to 50 ° C and stirred 1h, then add 10% 2,4-toluene diisocyanate, heat up to 80°C and react for 90min; then add 5% polyethylene adipate propylene glycol ester diol, continue stirring for 60min, cool to below 50°C Then add DMF to adjust the viscosity of the system, and finally add water to quickly emulsify to make the system solid content 35%.

[0045] Described composite flame retardant:

[0046] S1: Add the acidified attapulgite to ethanol for ultrasonic treatment, then add an equal mass of KH-570, stir and disperse evenly, then raise the temperature to 60-70°C, stir for 4-5h; centrifuge, wash with ethanol Collect the solid and dry it to obtain solid A; add 0.25 g of the collected solid A to the reaction flask, add 0.1 g of ammonium persulfate, 0.05 g of sodium bisulfite and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com