High-flame-retardant cold-resistant low-smoke halogen-free cable material and preparation process thereof

A high flame retardant and cable material technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem that the flame retardant level of polyethylene flame retardant cable materials is not up to the standard, the wire and cable are easy to crack or even embrittle, and the wire and cable Poor cable surface finish and other problems, to achieve the effect of reducing heat release rate, flame retardant and smoke suppression effect, and improving elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

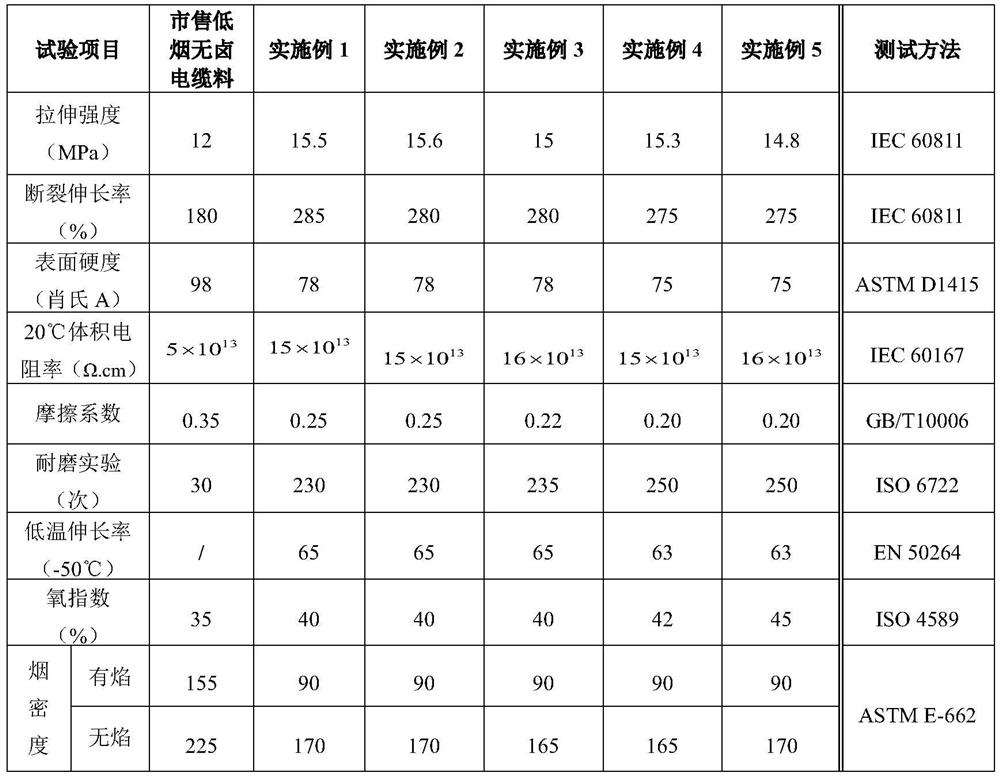

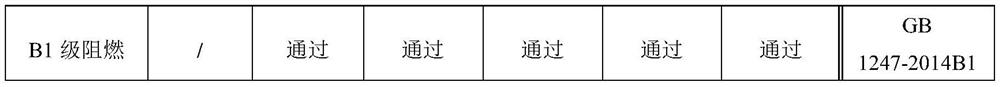

Examples

Embodiment 1

[0034] (1) Each raw material is weighed by the above-mentioned parts by weight, and the specific components are shown in Table 1; Diisodecyl adipate, hexamethylphosphoric triamide, nano silicon dioxide, montmorillonite, calcium zinc heat stabilizer, and triphenyl phosphate are added to the high-speed mixer, and the mixture is mixed at a low speed at 40 rpm. Mix for 5 minutes to obtain compound A;

[0035] (2) Add the mixture A, TMPTMA powder, DCP, antioxidant and lubricant obtained above to the high-speed mixer, and mix at a low speed for 5 minutes under the condition of 50 rpm to obtain the mixture B;

[0036](3) Put the mixture B into a banbury mixer for banburying. After banburying, air cooling is used to cool and solidify the mixture. After cooling, extrude and granulate with an extruder. The granulation adopts a twin-screw extruder to process Said compound is extruded, and the diameter of selecting twin-screw extruder is less than 250mm, and length-to-diameter ratio is 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com