Method for preparing boron-doped carbon nanosheet from lignin and product

A carbon nanosheet, lignin technology, applied in nanocarbon, chemical instruments and methods, other chemical processes, etc., can solve the problems of uneven quality, complex process, high porosity, etc., and achieve excellent uniformity, thin thickness, High ductility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

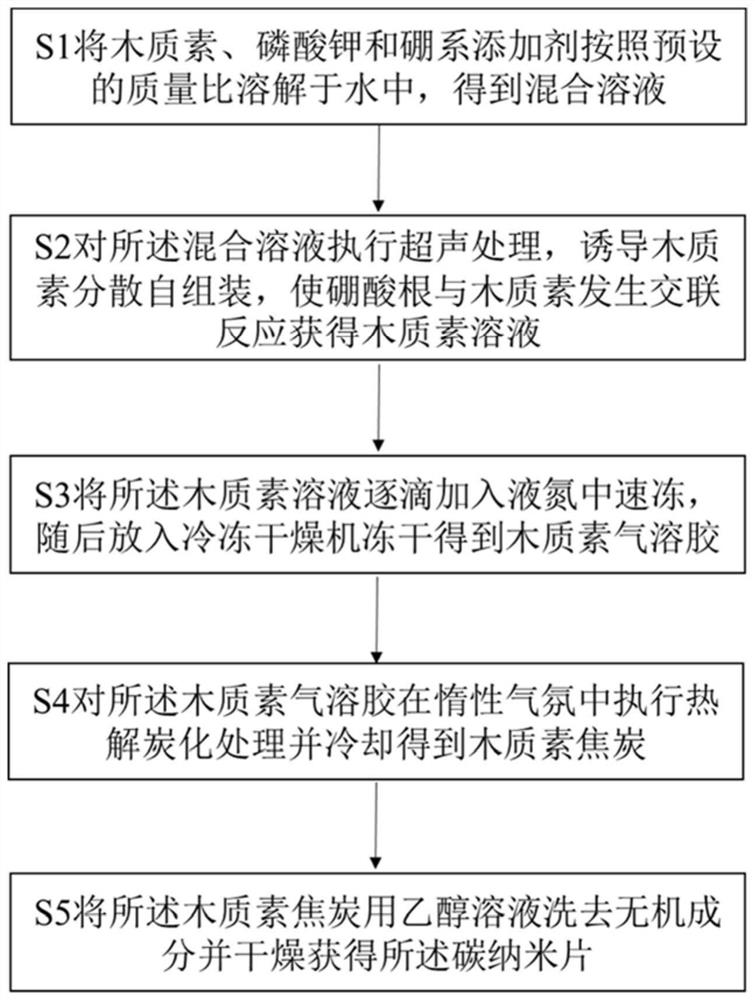

Method used

Image

Examples

Embodiment 1

[0053] S1 Dissolving alkali lignin, potassium phosphate and ammonium borate in water according to a preset mass ratio to prepare a mixed solution. Wherein, the mass range of lignin added per milliliter of water is 10 mg, the mass ratio of potassium phosphate to lignin is 1:1, and the mass ratio of ammonium borate to lignin is 1:12.

[0054] S2 Perform ultrasonic treatment on the mixed solution to fully dissolve potassium phosphate and boron-based additives, fully disperse lignin particles, induce self-assembly of lignin molecules, and fully undergo cross-linking and chelation reactions with borate groups to obtain lignin colloidal solution. Specifically, the power of the ultrasonic treatment is 100W, the frequency is 60Hz, and the time is 30min.

[0055] S3 Adding the lignin solution drop by drop into liquid nitrogen at a constant speed for rapid freezing, and then putting it into a freeze dryer to freeze-dry to obtain a lignin aerogel. Concretely, the dropping rate of the l...

Embodiment 2

[0060] S1 Dissolving alkali lignin, potassium phosphate and ammonium borate in water according to a preset mass ratio to prepare a mixed solution. Wherein, the mass range of lignin added per milliliter of water is 10 mg, the mass ratio of potassium phosphate to lignin is 1:10, and the mass ratio of ammonium borate to lignin is 1:12.

[0061] S2 Perform ultrasonic treatment on the mixed solution to fully dissolve potassium phosphate and boron-based additives, fully disperse lignin particles, induce self-assembly of lignin molecules, and fully undergo cross-linking and chelation reactions with borate groups to obtain lignin colloidal solution. Specifically, the power of the ultrasonic treatment is 100W, the frequency is 60Hz, and the time is 40min.

[0062] S3 Adding the lignin solution drop by drop into liquid nitrogen at a constant speed for rapid freezing, and then putting it into a freeze dryer to freeze-dry to obtain a lignin aerogel. Concretely, the dropping rate of the ...

Embodiment 3

[0067] S1 dissolving lignin, potassium phosphate and boron-based additives in water according to a preset mass ratio to prepare a mixed solution. Wherein, the lignin is alkali lignin, the mass range of lignin added per milliliter of water is 1 mg, and the mass ratio of potassium phosphate to lignin is 1:20. The boron additive is preferably boric acid, and the mass ratio of additive to lignin is 1:50.

[0068] S2 Perform ultrasonic treatment on the mixed solution to fully dissolve potassium phosphate and boron-based additives, fully disperse lignin particles, induce self-assembly of lignin molecules, and fully undergo cross-linking and chelation reactions with borate groups to obtain lignin colloidal solution. Specifically, the power of the ultrasonic treatment is 60W, the frequency is 40Hz, and the time is 10min.

[0069] S3 Adding the lignin solution drop by drop into liquid nitrogen at a constant speed for rapid freezing, and then putting it into a freeze dryer to freeze-d...

PUM

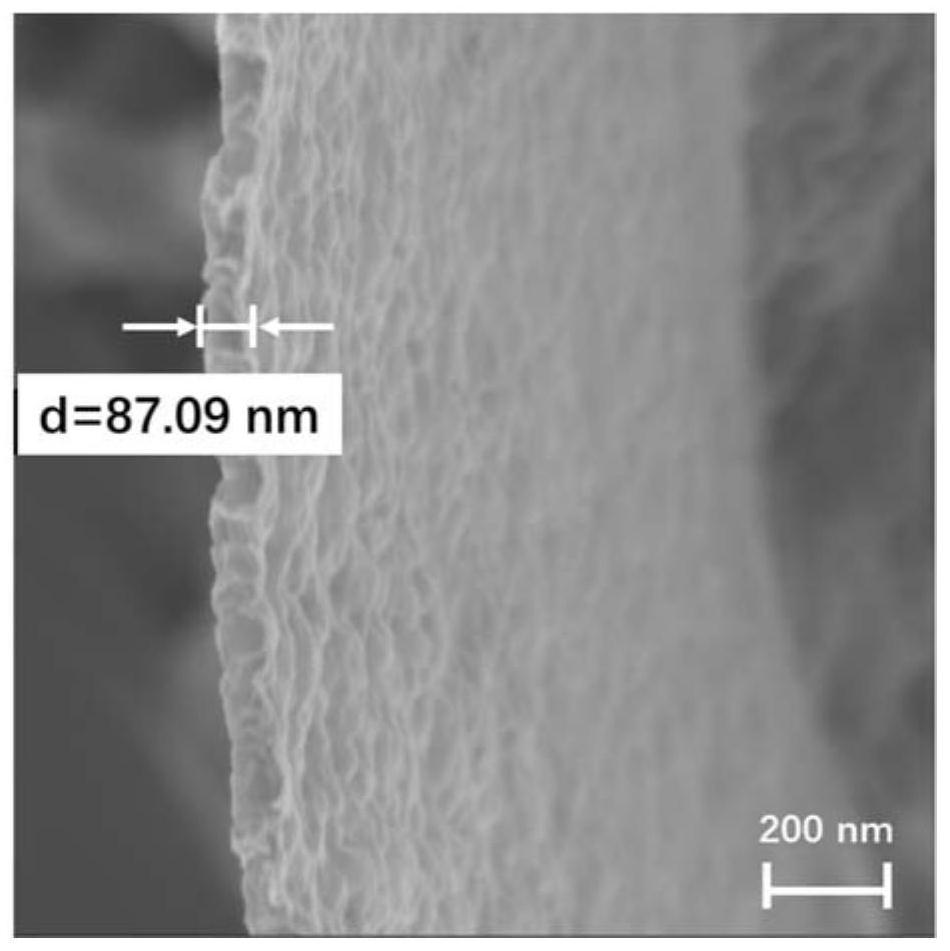

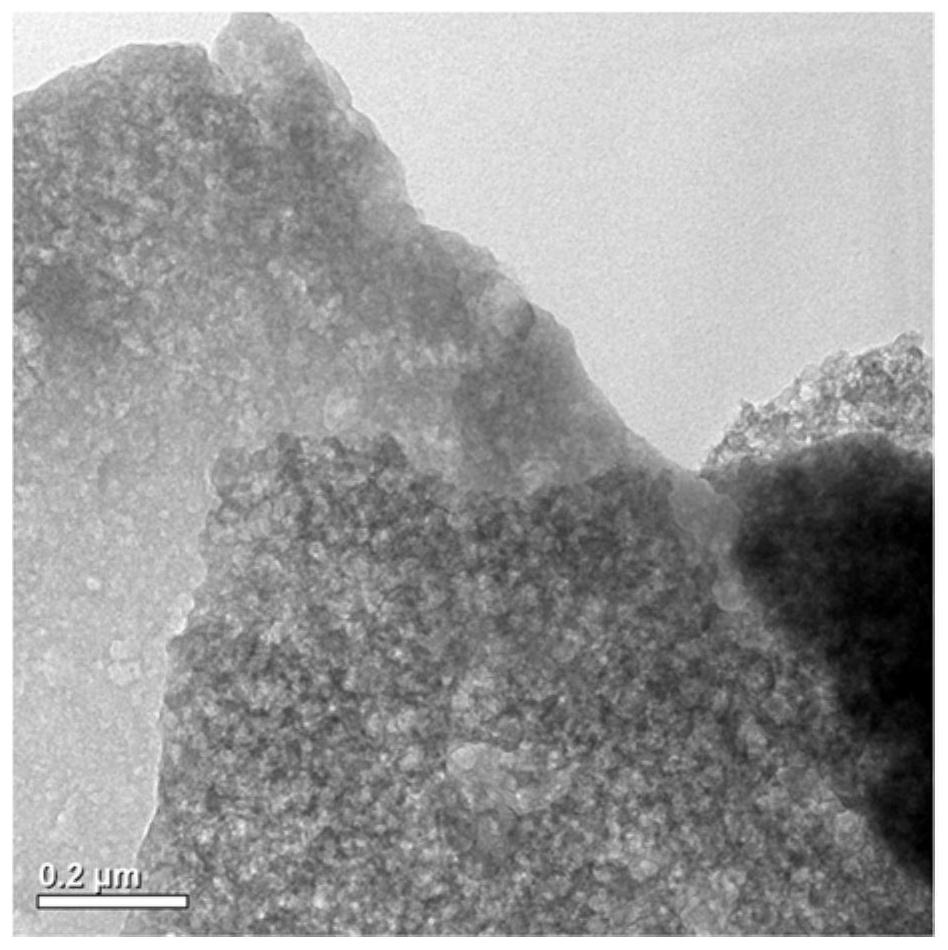

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com