Preparation method of oxysalt-based composite charge transport layer of perovskite solar cell

A charge transport layer and solar cell technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of carrier recombination loss, low photoelectric conversion efficiency, device short circuit current density, open circuit voltage and fill factor reduction, etc. , to achieve the effect of good repeatability, low production cost, simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

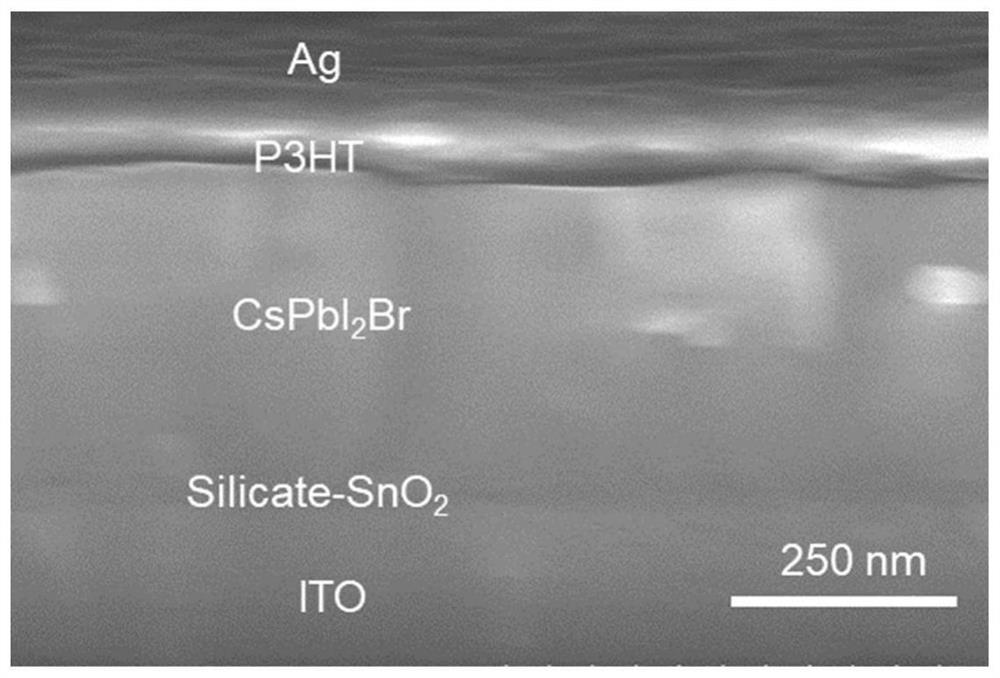

[0043]Step 1. Preparation of Oxygen Salt Composite Electron Transport Layer

[0044] First weigh 6.1 mg of sodium silicate and dissolve it in 1 mL of tin dioxide solution, wherein the concentration of the tin dioxide solution is 2.5 mg / mL. After stirring at room temperature for 6 h, the precursor solution of the oxygen-containing salt composite electron transport layer to be used was obtained. The conductive ITO substrate was cleaned in acetone, isopropanol, and aqueous solution for 30 minutes, and then cleaned in an oxygen plasma atmosphere for 3 minutes. The ITO substrate was placed in a spin coater, 30 μL of the electron transport layer precursor solution was dropped on the substrate, and spin-coated to form a film. Subsequently, the substrate was sent into a muffle furnace for calcination at 150° C. for 30 minutes to obtain a substrate with an oxygen-containing salt composite electron transport layer.

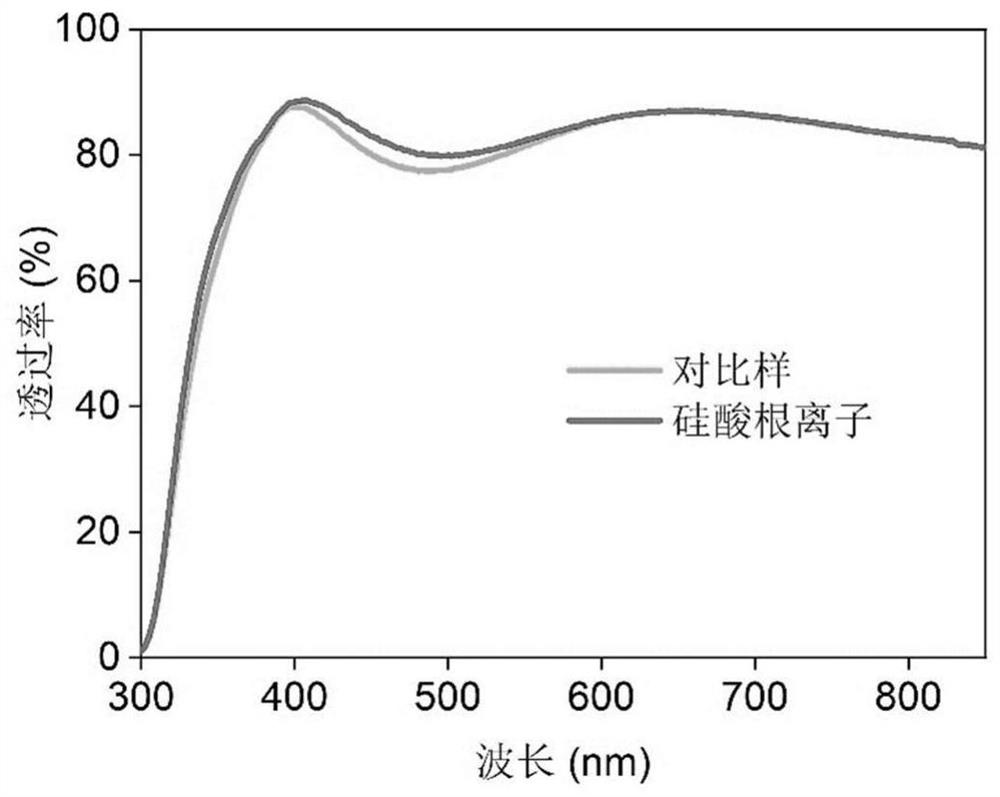

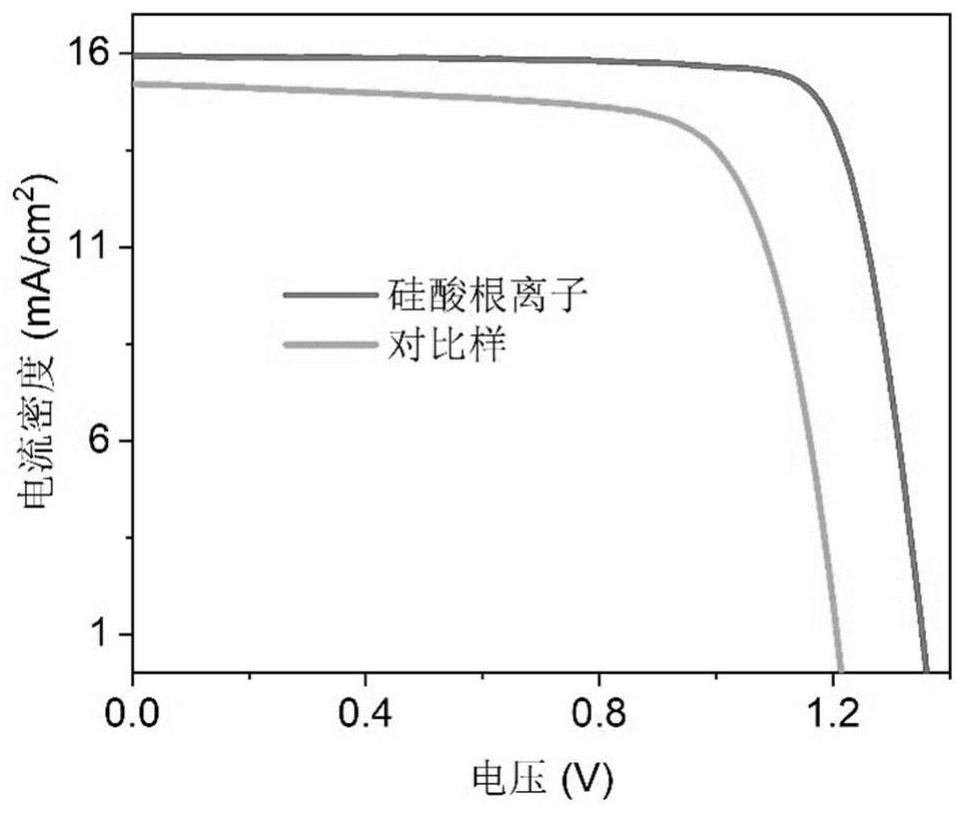

[0045] figure 1 For the prepared sodium silicate / tin dioxide compos...

Embodiment 2

[0057] First weigh 5.3 mg of sodium carbonate and dissolve it in 1 mL of tin dioxide solution, wherein the concentration of the tin dioxide solution is 2.5 mg / mL. After stirring at room temperature for 6 h, the precursor solution of the oxygen-containing salt composite electron transport layer to be used was obtained. The conductive ITO substrate was cleaned in acetone, isopropanol, and aqueous solution for 30 minutes, and then cleaned in an oxygen plasma atmosphere for 3 minutes. A layer of oxo-salt composite electron transport layer with a thickness of 10 nm was deposited on the ITO conductive substrate by spraying. Subsequently, the substrate was sent into a muffle furnace for calcination at 150° C. for 30 minutes to obtain a substrate with an oxygen-containing salt composite electron transport layer. Dissolve 311.77mg of cesium iodide, 276.61mg of lead iodide, and 220.2mg of lead bromide in 1mL of DMSO, stir for 12h, and configure 1.2mol / L CsPbI 2 Br perovskite precursor...

Embodiment 3

[0060] First weigh 7.1 mg of sodium sulfate and dissolve it in 1 mL of tin dioxide solution, wherein the concentration of the tin dioxide solution is 2.5 mg / mL. After stirring at room temperature for 6 h, the precursor solution of the oxygen-containing salt composite electron transport layer to be used was obtained. The conductive ITO substrate was cleaned in acetone, isopropanol, and aqueous solution for 30 minutes, and then cleaned in an oxygen plasma atmosphere for 3 minutes. A layer of oxo-salt composite electron transport layer with a thickness of 10 nm was deposited on the ITO conductive substrate by spraying. Subsequently, the substrate was sent into a muffle furnace for calcination at 150° C. for 10 minutes to obtain a substrate with an oxygen-containing salt composite electron transport layer. Dissolve 311.77mg of cesium iodide, 276.61mg of lead iodide, and 220.2mg of lead bromide in 1mL of DMSO, stir for 12h, and configure 1.2mol / L CsPbI 2 Br perovskite precursor s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com