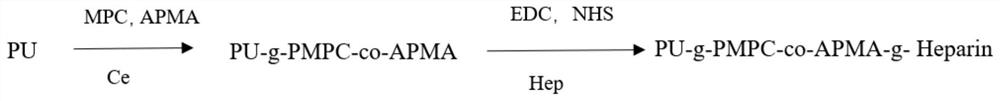

Modified polymeric membrane material and preparation method thereof

A polymer film and modification technology, applied in the types of packaging items, special packaging items, packaging, etc., can solve the problems of limited amino or carboxyl group content on the surface of the film, low heparin grafting efficiency, affecting the mechanical properties of the film, etc. Anticoagulant properties, good market application prospects, and the effect of reducing platelet adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In this embodiment, the polymer membrane material is polyurethane membrane.

[0050] In this embodiment, the preparation steps of the unmodified polyurethane film include: dissolving the polyurethane pellets in dimethylacetamide to prepare a polyurethane solution with a mass concentration of 12%, pouring the polyurethane solution into a polytetrafluoroethylene mold, and evenly spreading Open it, put it into a vacuum drying oven, dry it in vacuum at 50°C for 24 hours, take out the mold, wait for the temperature to drop to room temperature, add purified water, take out the film, wash it, and dry it at room temperature or in vacuum for later use to obtain a flat polyurethane film, and put the polyurethane The membranes were divided into two groups, the control group and the test group, with 3 pieces in each group; among them,

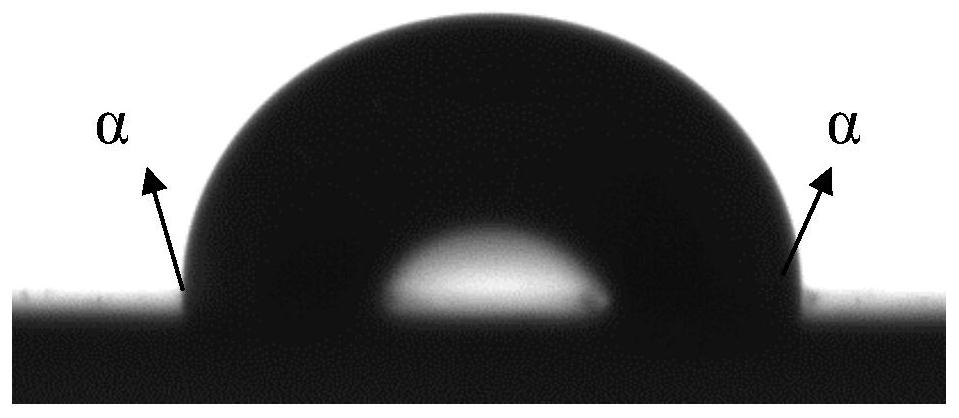

[0051] Control group: the flat polyurethane film was washed in PBS solution and cut into 10*10mm sheets for contact angle and platelet adhesion tes...

Embodiment 2

[0057] The difference with Example 1 is:

[0058] In the present embodiment, the preparation steps of the unmodified polyurethane film include: dissolving the polyurethane pellets in dioxane to prepare a polyurethane solution with a mass concentration of 15%, pouring the polyurethane solution into a polytetrafluoroethylene mold, and spreading it evenly , put it into a vacuum drying oven, dry it in vacuum at 50°C for 24 hours, take out the mold, wait until the temperature drops to room temperature, add purified water, take out the film, wash it, dry it at room temperature or in vacuum for later use, obtain a flat polyurethane film, and put the polyurethane film Divided into two groups of control group and test group, each group has 3 tablets;

[0059] Control group: the flat polyurethane film was washed in PBS solution and cut into 10*10mm sheets for contact angle and platelet adhesion tests;

[0060] Test group: the first step, prepare 100ml of pretreatment solution containin...

Embodiment 3

[0064] The difference with Example 1 is:

[0065] In this embodiment, the preparation steps of the unmodified polyurethane film include: dissolving the polyurethane pellets in a solvent of tetrahydrofuran / dioxane=1:1 to prepare a polyurethane solution with a mass concentration of 15%, pouring the polyurethane solution into Spread the polytetrafluoroethylene mold evenly, put it in a vacuum drying oven, and dry it in vacuum at 50°C for 24 hours, then take out the mold, wait until the temperature drops to room temperature, add purified water, take out the film, wash it, and dry it at room temperature or in vacuum for later use. Smooth polyurethane film, and polyurethane film is divided into control group and test group two groups, every group 3; Wherein,

[0066] Control group: the flat polyurethane film was washed in PBS solution and cut into 10*10mm sheets for contact angle and platelet adhesion tests;

[0067] Test group: first step, prepare 100ml of pretreatment solution con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graft density | aaaaa | aaaaa |

| Graft density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com