Two-dimensional metal titanium carbide loaded MnOx quantum dot electrode material and application thereof

An electrode material, titanium carbide technology, applied in the field of materials, can solve the problems of low specific capacity and poor rate performance, and achieve high specific capacity, improve rate performance, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of two-dimensional metal titanium carbide nanosheets: 2g lithium fluoride and 9M 40ml hydrochloric acid were stirred in a Teflon beaker for 30min; 2g Ti 3 AlC 2 Slowly add to the above beaker, continue to stir for 24h (keep the temperature at 35°C), centrifuge the obtained reaction liquid (3500rpm, 10min), pour off the supernatant after centrifugation, then add 40ml of deionized water to the precipitate, and dissolve the solution Pour it into a three-neck bottle, add ice cubes, and sonicate at low temperature for 30 minutes (maintained by Ar gas), take it out and continue centrifuging (3500rpm, 10min), repeat several times until the pH value of the liquid poured out after centrifugation reaches 5, and collect the lower sediment; Add 40ml of ethanol to the sediment and sonicate at low temperature for 1h, centrifuge (8000 rpm, 20min), and collect the lower sediment; liquid; the black rice-colored liquid was subpackaged and freeze-dried to obtain MXene powder....

Embodiment 2

[0041] Preparation of manganese oxide@MXene: 1mg of Mn 2 (CO) 10 Dissolve in 5mL of N,N-dimethylformamide (DMF), then pipette 0.25mL of octylamine dropwise to the above Mn 2 (CO) 10 20mg of MXene prepared in Example 1 was then dispersed into 10mL of DMF under ultrasonic assistance for 5min; then the Mn containing octylamine 2 (CO) 10 DMF solution was added dropwise to 10mL of MXene dispersion under stirring condition, and ultrasonicated for 10min to make it evenly mixed. Finally, the above mixed liquid was transferred to a polytetrafluoro-lined stainless steel autoclave, and 0.1 g of ascorbic acid was added as an antioxidant, and the reaction was kept at 170° C. for 2 h. The above solution was suction filtered, washed with absolute ethanol and deionized water several times, and then freeze-dried to obtain MnO x NDs@MXene composites, x = 4 / 3.

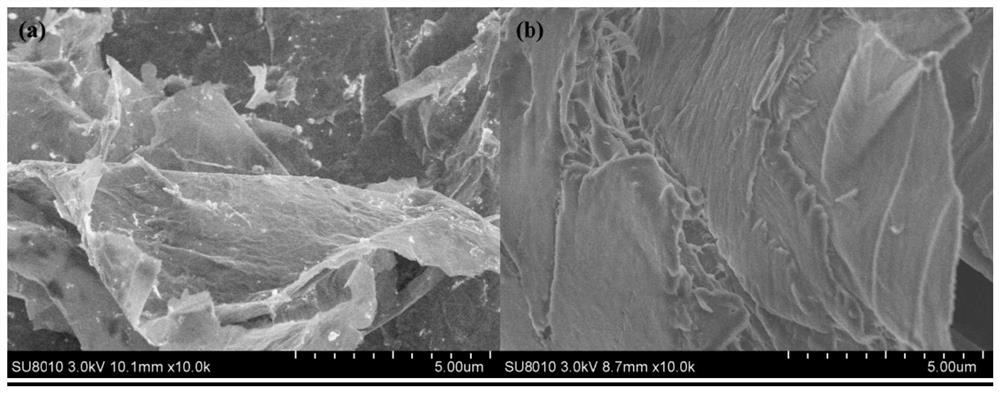

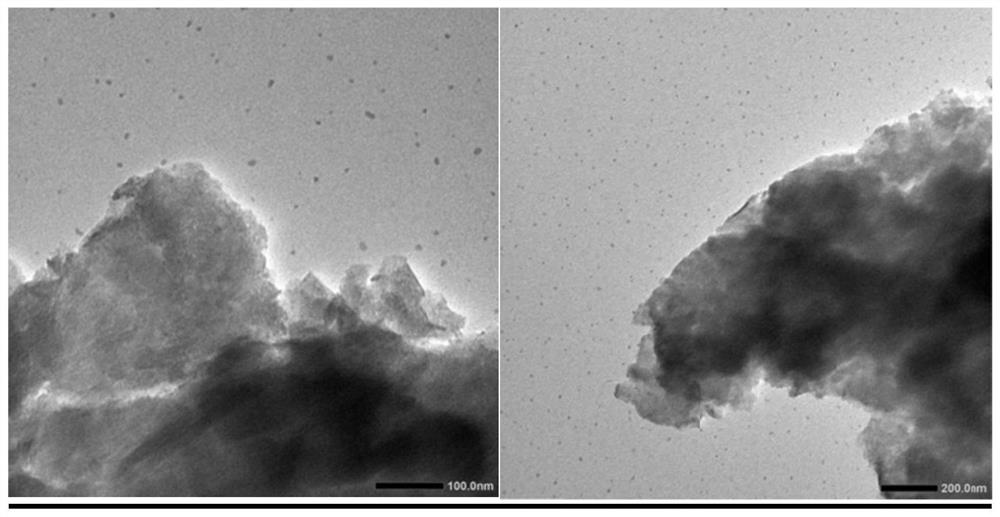

[0042] From figure 1 b and figure 2 It is known that the MXene loaded MnO prepared according to the above experimental steps ...

Embodiment 3

[0044] Manganese oxide@MXene electrode was prepared and its electrochemical performance was tested; the MnO x NDs@MXene material, graphite powder and polytetrafluoroethylene emulsion are mixed uniformly at 85wt%, 15wt%, and 5wt% by weight, and then coated on the foamed nickel sheet, and the foamed nickel sheet coated with the electrode material is rolled and dried, and then cut into Carbon quantum dot electrode sheet; the electrolyte is 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIM-BF 4 ) ionic liquid.

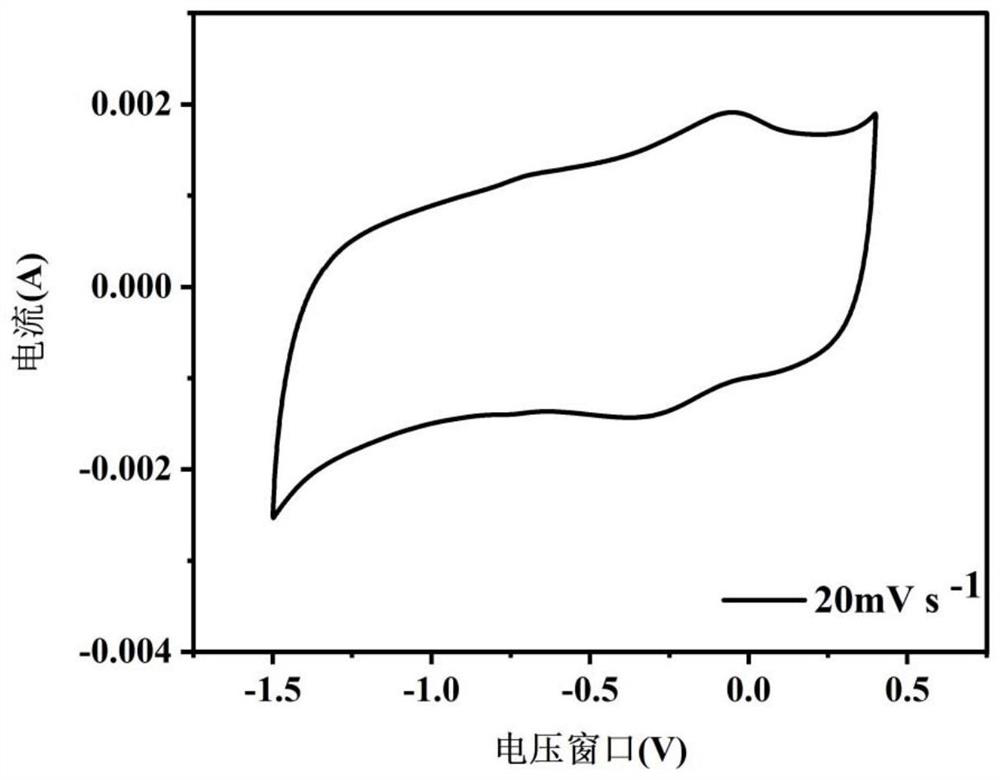

[0045] From image 3 It is known that in this example, the manganese oxide quantum dot-loaded MXene composite electrode uses EMIM-BF in the three-electrode system 4 The cyclic voltammetry curve measured when the ionic liquid is used as the electrolyte scan rate is 20mV / s, from the CV curve, the voltage window is -1.5V-0.5V, which has a similar rectangular shape, indicating that it has a relatively ideal capacitance behavior. The curve shows a pair of obvious redox pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flow density | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com