High-strength heat-resistant high-entropy alloy and forging/rolling forming method

A high-entropy alloy and high-strength technology, applied in the field of high-entropy alloys, can solve the problems of high price of refractory elements, poor oxidation resistance, high room temperature brittleness, etc., and achieve the effect of obvious advantages in high-temperature strength, excellent plasticity, and high-temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The heat-resistant high-entropy alloy cast steel ingot of 5 kg is prepared by using a water-cooled copper plate vacuum induction melting furnace, and the specific preparation steps are as follows:

[0031] Step 1, select Al, Co, Cr, Fe, Ni, Mo, Nb, Hf, C raw materials with a purity of 99.9% and above, successively by mass percentage 8.05%, 17.57%, 15.5%, 16.65%, 32.82%, 6.79% %, 1.73%, 0.67%, 0.22% ingredients.

[0032] Step 2, melt the processed high-entropy alloy raw material in a vacuum electromagnetic induction furnace, and pour it into a water-cooled copper mold after melting;

[0033] Step 3, using circulating water cooling to achieve the purpose of rapid cooling.

[0034] figure 1 It is a 5kg grade ingot of the heat-resistant high-entropy alloy, and the ingot is complete without cracking and has few defects.

Embodiment 2

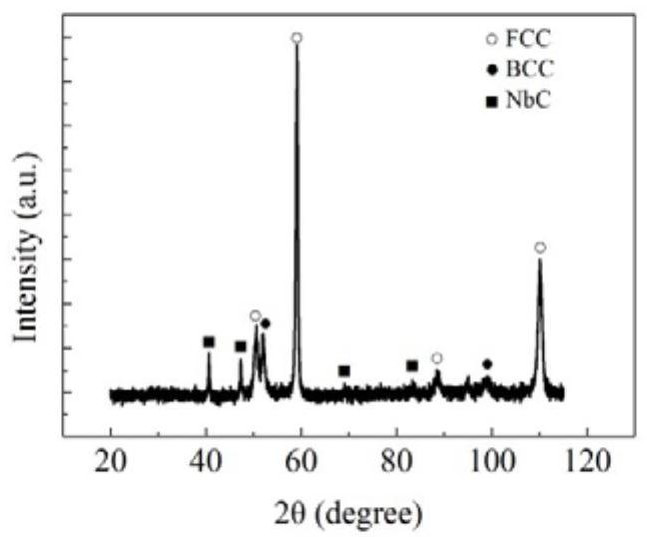

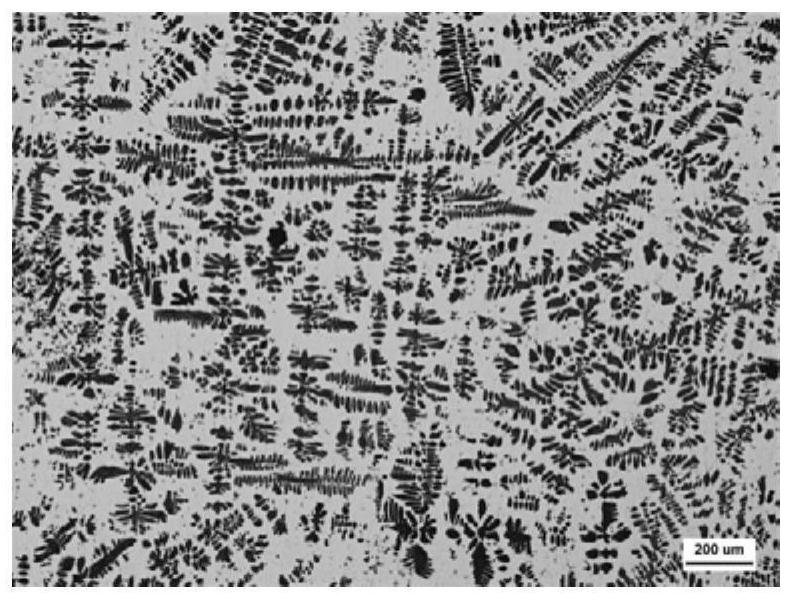

[0036]The sample is prepared by wire cutting, the sample is ground with silicon carbide paper, and then the surface is polished to make the surface of the sample smooth. The chemical etchant used to observe the alloy structure is ferric chloride and cupric chloride solution, and the electrochemical etchant is chromic acid aqueous solution. Chemical corrosion can be used to observe the Cr-rich and Mo-rich phases in the alloy, and can corrode the Ni-rich and Al-rich phases. The Ni-rich and Al-rich phases in the alloy were observed by electrolytic corrosion method. The microstructure of the high entropy alloy was observed by Hitachi S-4300 scanning electron microscope and Hitachi H-800 transmission electron microscope. Phase analysis instruments are German dual-channel scanning inductively coupled plasma atomic emission spectrometer (ICP-AES) and APD-10 X-ray diffractometer (CoKα, 30kV, 25mA). The scanning angle is 20°~100°, and the scanning speed is 4° / min.

[0037] figure ...

Embodiment 3

[0041] Tensile tests were performed using an Instran tensile tester. The room temperature tensile standard is GB / T 228.1-2010, and the high temperature tensile test standard is GB / T 228.2-2015.

[0042] Figure 6 It is the high-temperature performance of the alloy at room temperature. At 700°C, the tensile strength, yield strength, and elongation are 775MPa, 532MPa, and 23% respectively, wherein the tensile strength reaches about 85% of that at room temperature, and the elongation is about 85% at room temperature 700% of.

[0043] Table 1, Figure 7 AlCoCrFeNi is widely studied for the alloy and is currently stretchable and has heat-resistant potential 2.1 Compared with the high-temperature performance of AlCoCrFeNi high-entropy alloy at 700 °C, the high-temperature performance has obvious advantages.

[0044] Table 1 Comparison of the tensile properties of the alloy of the present invention and the existing alloy at 700 °C

[0045] alloy Yield strength / MPa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com