Arsenic sulfide slag wet mineralization detoxification treatment method

A treatment method, arsenic sulfide technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of complex types of agents, harsh process conditions, long treatment cycle, etc., to improve the efficiency of mineral conversion , high oxidation efficiency and low treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

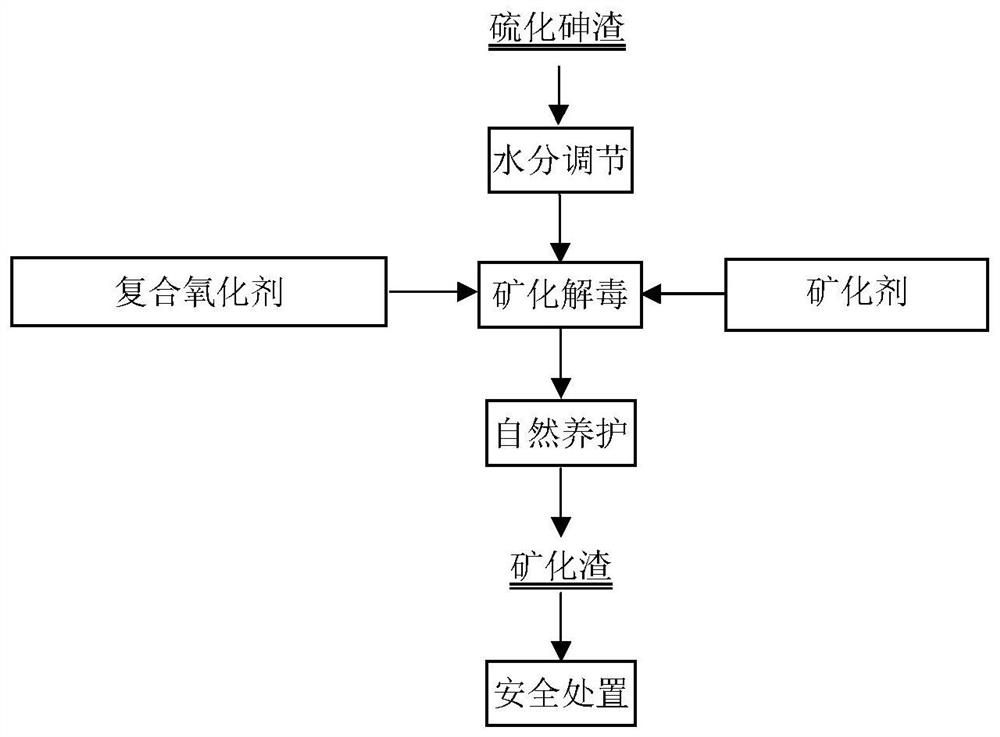

Method used

Image

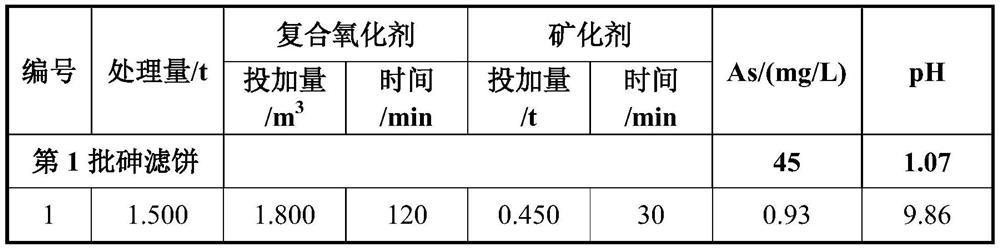

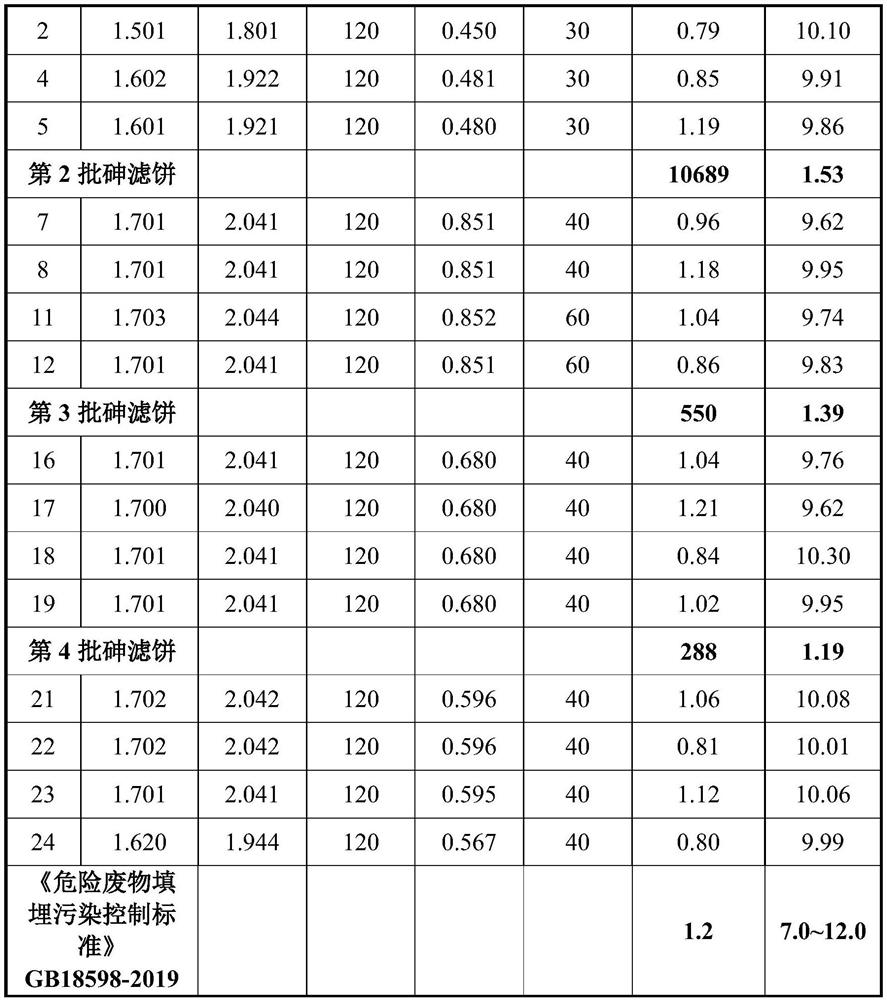

Examples

Embodiment 1

[0040] Preparation of composite oxidant:

[0041] Choose hydrogen peroxide with a mass concentration of 30% as an oxidant, and choose concentrated sulfuric acid with a mass concentration of 98% as an acid regulator. Weigh 40g of hydrogen peroxide, 1.2g of concentrated sulfuric acid, and 18.8g of pure water, and mix the three to make a composite oxidant, wherein the mass concentration of hydrogen peroxide is 20%, and the mass concentration of sulfuric acid is 2%.

[0042] Preparation of mineralizer:

[0043] Use magnesite as the magnesium source of the main ingredient A, the magnesium content is 25wt%, the crushed magnesite particle size is 3mm, the calcination temperature is 800°C, the holding time is 2h, the furnace is cooled to 300°C, taken out, and ground to 200 mesh Sieve, take the sieve to obtain the main ingredient A; kaolin is used as the aluminum source of the auxiliary ingredient B, the aluminum content is 21wt%, the crushing particle size is 3mm, the drying temperat...

Embodiment 2

[0055] Preparation of composite oxidant:

[0056] Choose hydrogen peroxide with a mass concentration of 30% as an oxidant, and choose concentrated sulfuric acid with a mass concentration of 98% as an acid regulator. Weigh 30g of hydrogen peroxide, 1.8g of concentrated sulfuric acid, and 28.2g of pure water, and mix the three to make a composite oxidant, wherein the mass concentration of hydrogen peroxide is 15%, and the mass concentration of sulfuric acid is 3%.

[0057] Preparation of mineralizer:

[0058] Use magnesite as the magnesium source of the main ingredient A, the magnesium content is 25wt%, the crushed magnesite particle size is 6mm, the calcination temperature is 825°C, the holding time is 3h, the furnace is cooled to 300°C, taken out, and ground to 200 mesh Sieve, take the sieve to obtain the main ingredient A; kaolin is used as the aluminum source of the auxiliary ingredient B, the aluminum content is 21wt%, the crushing particle size is 6mm, the drying temperat...

Embodiment 3

[0071] Preparation of composite oxidant:

[0072] Choose hydrogen peroxide with a mass concentration of 30% as an oxidant, and choose concentrated sulfuric acid with a mass concentration of 98% as an acid regulator. Weigh 20g of hydrogen peroxide, 3.0g of concentrated sulfuric acid, and 37g of pure water, and mix the three to make a composite oxidant, wherein the mass concentration of hydrogen peroxide is 10%, and the mass concentration of sulfuric acid is 5%.

[0073] Preparation of mineralizer:

[0074] Use magnesite as the magnesium source of the main ingredient A, the magnesium content is 25wt%, the crushed magnesite particle size is 9mm, the calcination temperature is 850°C, the holding time is 4h, the furnace is cooled to 300°C, taken out, and ground to 200 mesh Sieve, take the sieve to obtain the main ingredient A; kaolin is used as the aluminum source of the auxiliary ingredient B, the aluminum content is 21wt%, the crushing particle size is 9mm, the drying temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com