Fireproof flame-retardant polymer light building external wall thermal insulation composite board and preparation process thereof

A technology for thermal insulation composite panels and building exterior walls, used in thermal insulation, fire protection, construction, etc., can solve the problems of long curing time, poor weather resistance, low tensile strength, etc., to reduce density and thermal conductivity, improve strength and resistance. flammability, improved strength and weatherability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

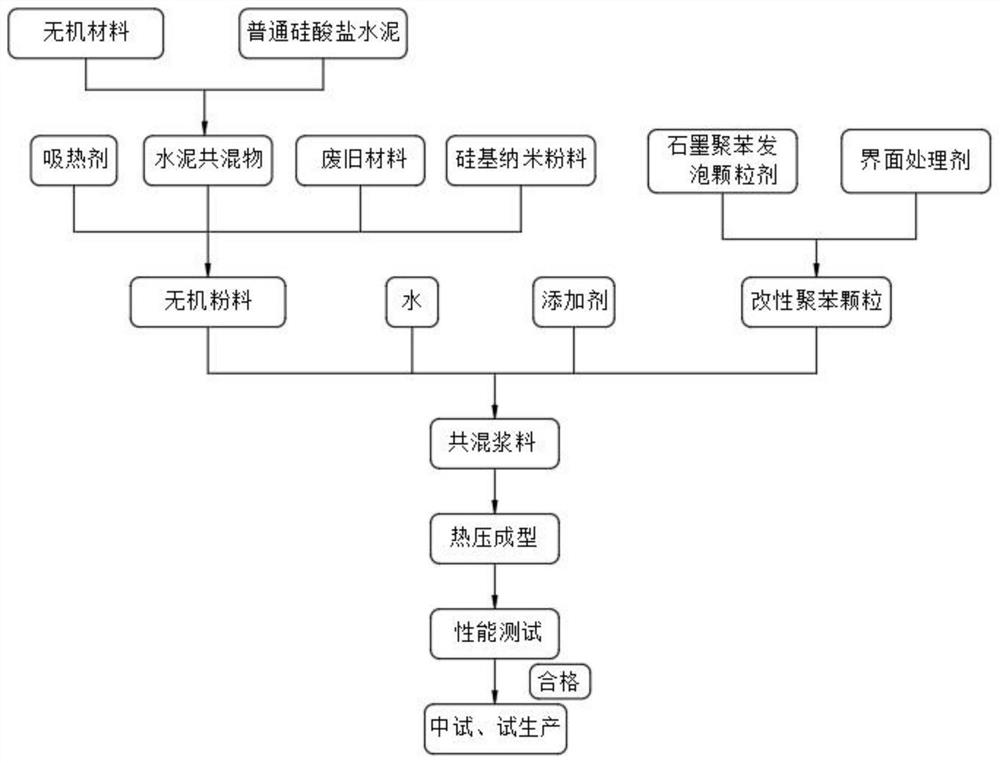

Method used

Image

Examples

Embodiment 1

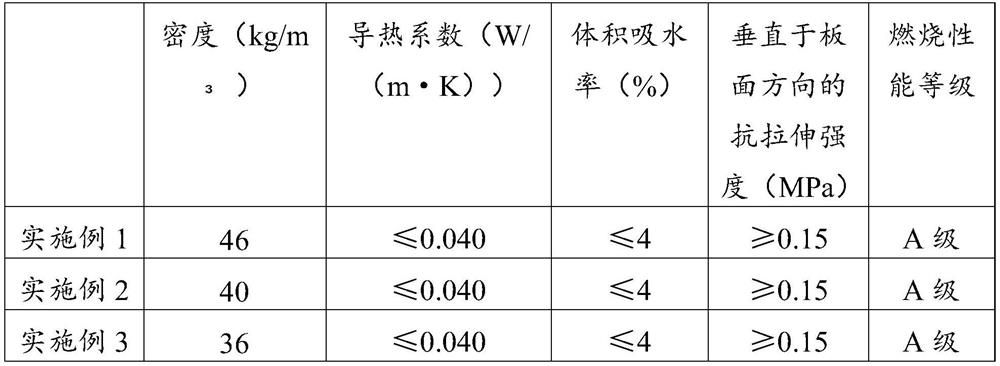

[0040] The invention provides a fire-resistant and flame-retardant polymer lightweight building exterior wall thermal insulation composite board. The raw materials used (by weight) include 10 parts of inorganic materials, 20 parts of ordinary portland cement, 1 part of heat absorbing agent, waste materials 2 parts, 10 parts of silicon-based nanopowder, 20 parts of graphene foaming granules, 1 part of interface treatment agent, 1 part of additive, and 20 parts of water.

[0041] Described inorganic material (by parts by weight) comprises 40 parts of nano silicon dioxide, 20 parts of magnesia and igneous rock fiber 20 parts; Described endothermic agent is PCM material; Described interface treatment agent (by weight parts Total) includes 30 parts of epoxy resin, 2 parts of nano-calcium carbonate, 20 parts of acrylic acid, 6 parts of calcium formate, 2 parts of quartz sand, and 1 part of curing agent; the epoxy resin is epoxy resin E-42, and the curing The agent is vinyltriamine. ...

Embodiment 2

[0052] The invention provides a fire-resistant and flame-retardant polymer light-weight building exterior wall thermal insulation composite board. The raw materials used (by weight) include 12.5 parts of inorganic materials, 30 parts of ordinary portland cement, 5.5 parts of heat-absorbing agents, and waste materials. 6 parts, 15 parts of silicon-based nano powder, 25 parts of graphene foaming granules, 3 parts of interface treatment agent, 3 parts of additive, 30 parts of water.

[0053] Described inorganic material (by parts by weight) comprises 45 parts of nano silicon dioxide, 25 parts of magnesia and 25 parts of igneous rock fibers; Described endothermic agent is PCM material; Described interface treatment agent (by weight parts Total) includes 40 parts of epoxy resin, 6 parts of nano calcium carbonate, 25 parts of acrylic acid, 12 parts of calcium formate, 4 parts of quartz sand, and 3.5 parts of curing agent; the epoxy resin is epoxy resin E-44, and the curing The agent...

Embodiment 3

[0064] The invention provides a fire-resistant and flame-retardant polymer lightweight building exterior wall thermal insulation composite board. The raw materials used (by weight) include 15 parts of inorganic materials, 40 parts of ordinary portland cement, 10 parts of heat absorbing agent, waste materials 10 parts, 20 parts of silicon-based nano powder, 30 parts of graphene foaming granules, 5 parts of interface treatment agent, 5 parts of additives, 40 parts of water.

[0065] Described inorganic material (by parts by weight) comprises 50 parts of nano silicon dioxide, 30 parts of magnesia and 30 parts of igneous rock fibers; Described endothermic agent is PCM material; Described interface treatment agent (by weight parts Total) includes 50 parts of epoxy resin, 10 parts of nano-calcium carbonate, 30 parts of acrylic acid, 20 parts of calcium formate, 8 parts of quartz sand, and 6 parts of curing agent; the epoxy resin is epoxy resin E-52, and the curing The agent is dieth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com