Cationic liposome with high gene transfection efficiency and preparation and application thereof

A technology of cationic lipids and amino groups, which is applied in the directions of organic chemistry, the use of microcapsules, and other methods of inserting foreign genetic materials, can solve the problems of complex preparation methods, low transfection efficiency, unstable prices, etc., and achieves simple preparation methods. , Improve transfection efficiency and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

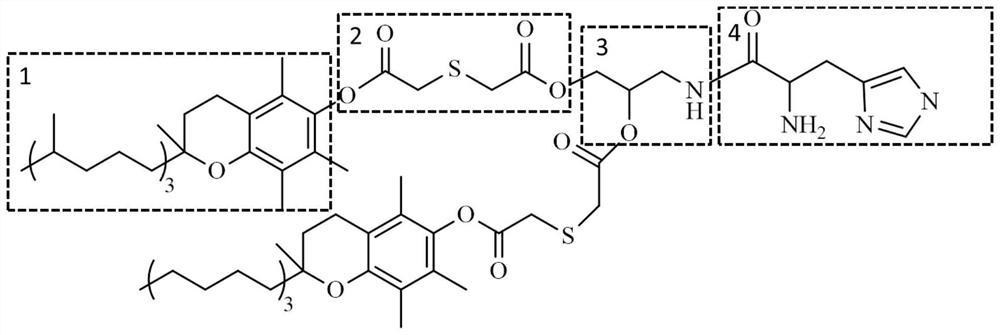

[0055] A method for preparing an amphiphilic cationic lipid material of the present invention comprises the following steps:

[0056] (1) Reflux the compound containing monosulfide bond, disulfide bond, disulfide bond, diselenide bond, monoselenide bond or diselenide bond in acetyl chloride to obtain product A;

[0057] (2) Dissolve vitamin E, cholesterol, cis-9-octadecenol, catalyst 4-dimethylaminopyridine and the product A obtained in step (1) in an organic solvent, and stir and react at 50°C-80°C for 12h -36h, obtain product B;

[0058] (3) The product B obtained in step (2), 3-amino-1,2-propanediol, catalyst 4-dimethylaminopyridine and catalyst 1-(3-dimethylaminopropyl)-3-ethyl carbon Diimine hydrochloride was dissolved in an organic solvent, stirred and reacted at 25°C-37°C for 16h-24h to obtain product C;

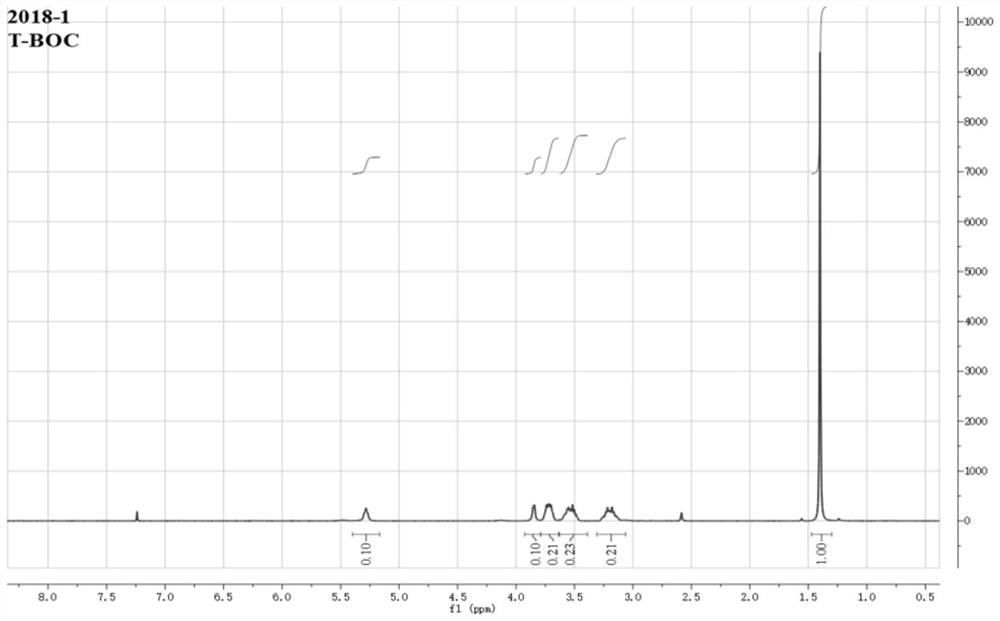

[0059] (4) dissolving the product C obtained in step (3) in an organic solvent, adding trifluoroacetic acid equal to the volume of the organic solvent, stirring and...

Embodiment 1

[0082] This embodiment provides a method for preparing a novel amphiphilic cationic lipid material sensitive to esterase, which is synthesized through the following steps:

[0083](1) Synthesis of VE-COOH: 4.3g of vitamin E (VE), 1.5g of succinic anhydride (SA) and 3.15g of triethylamine were weighed into a 100mL round bottom flask, and 50mL of dichloromethane was added. After stirring and dissolving at 70°C, the reflux reaction was continued for 24h. After the reaction, add 50 mL of deionized water for extraction three times, dry the organic layer with anhydrous sodium sulfate overnight, filter, and remove the organic solvent by rotary evaporation. The obtained oil is dissolved in three times the amount of n-hexane at 60°C, and then gradually cooled to room temperature , and then recrystallized overnight at 4°C. After filtration, a white powdery solid was obtained, and the obtained white powder was vacuum-dried overnight at 40° C. to remove residual organic solvents to obtai...

Embodiment 2

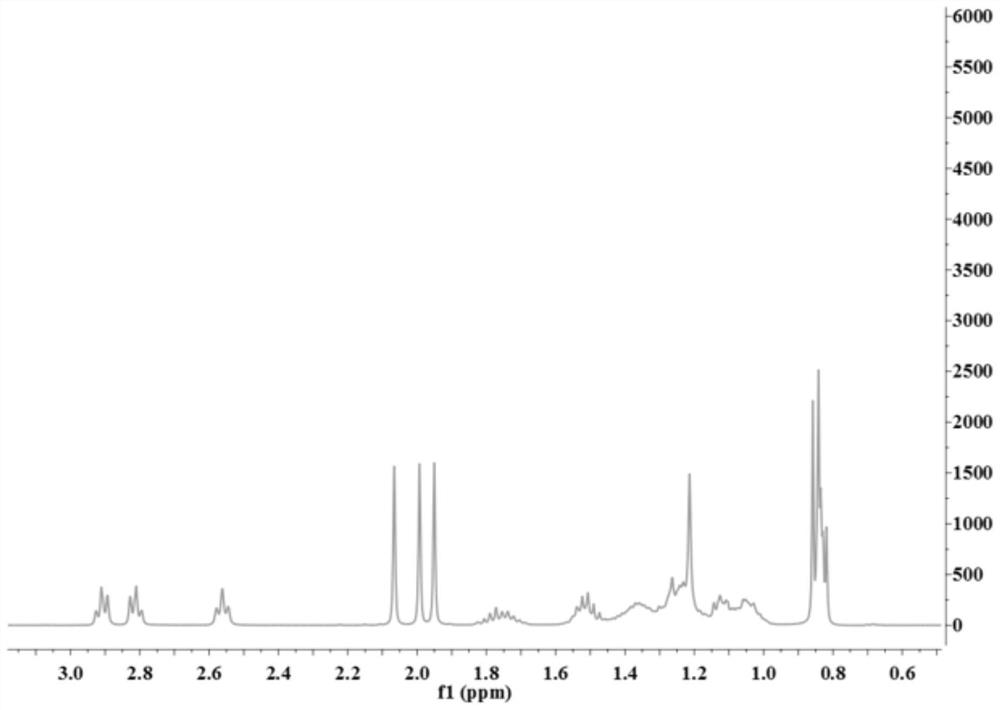

[0097] This example provides a method for preparing a novel amphiphilic cationic lipid material with redox sensitivity, which is synthesized through the following steps:

[0098] (1) Synthesis of 2,2'-thiodiacetic anhydride: Weigh 3.0 g of 2,2'-thiodiacetic acid into a 50 mL round-bottomed flask, and add 25 mL of acetic anhydride. After reflux reaction at 65°C for 4 hours, distill under reduced pressure to remove acetic anhydride, acetic acid, etc.; add an appropriate amount of ether, and repeat the rotary evaporation 2-3 times to obtain a white solid powder, which is dried in vacuum at 40°C overnight to obtain 2,2'-sulfur Substitute diacetic anhydride, the productive rate is 98.7%.

[0099] (2) Synthesis of VE-S-COOH: Weigh 4.3g of vitamin E (VE), 1.98g of 2,2-thiodiacetic anhydride and 1.12g of 4-dimethylaminopyridine in a 100mL round bottom flask, add 50mL dichloromethane. After stirring and dissolving at 70°C, the reflux reaction was continued for 36h. After the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com