Highly wear-resistant corrosion-resistant scrubber polyurethane tire

A polyurethane tire, anti-corrosion technology, applied in the field of polyurethane, can solve the problems affecting product life, etc., achieve the effect of improving high temperature resistance, not easy to hydrolyze, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

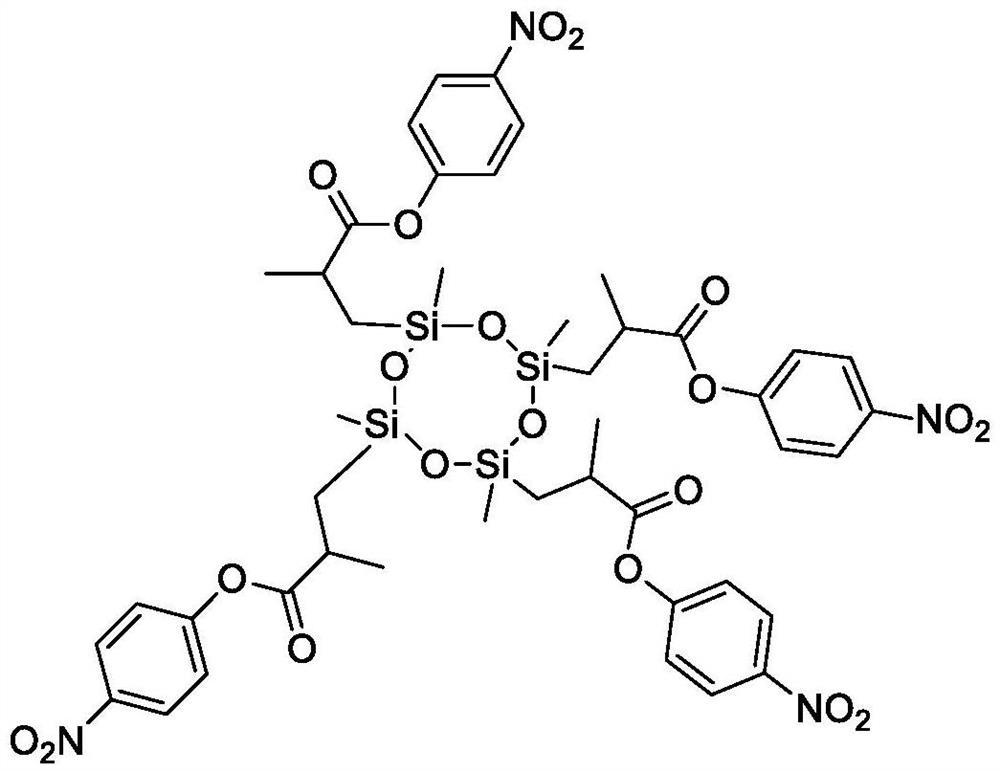

[0033] Prepare the chain extender:

[0034] Step S11, at a temperature of 0°C, mix p-nitrophenol, tetrahydrofuran and triethylamine, then add methacryloyl chloride, keep the temperature constant after the addition, and continue stirring for 10 hours. After the reaction, you will get The reaction solution was concentrated under reduced pressure to remove the solvent, then dissolved with chloroform, and then washed with 1% hydrochloric acid solution and 3% sodium hydroxide solution successively, and the solvent was removed after washing to obtain the auxiliary agent; control p-nitrophenol, methyl The dosage ratio of acryloyl chloride, tetrahydrofuran and triethylamine is 0.015mol: 0.015mol: 40mL: 2mL;

[0035] Step S12, under the condition of nitrogen protection, mix the additive and hydroquinone, add chloroplatinic acid, then slowly add 1,3,5,7-tetramethylcyclotetrasiloxane dropwise, and raise the temperature to 65°C, After the addition, keep the temperature constant, stir for...

Embodiment 2

[0038] Preparation of anti-hydrolysis agent:

[0039] At a temperature of 180°C and nitrogen protection, add isocyanate-propyltriethoxysilane to 3-methyl-1-phenyl-2-cyclobutene-1-oxide, and stir for 4 hours to obtain Anti-hydrolysis agent. The amount of 3-methyl-1-phenyl-2-cyclobutene-1-oxide added is 0.75% of the mass of isocyanate propyltriethoxysilane.

Embodiment 3

[0041] Preparation of polyester polyol:

[0042] Mix dibasic acid and polyol with a mass ratio of 10:7, add tetraisopropyl titanate, heat to 233°C under nitrogen protection, and react until the acid value drops below 1mgKOH / g, and the hydroxyl value The reaction is stopped below 114mgKOH / g to obtain polyester polyol, wherein the dibasic acid is sebacic acid, and the polyol is a mixture of new diol and trimethylolpropane at a mass ratio of 10-50:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com