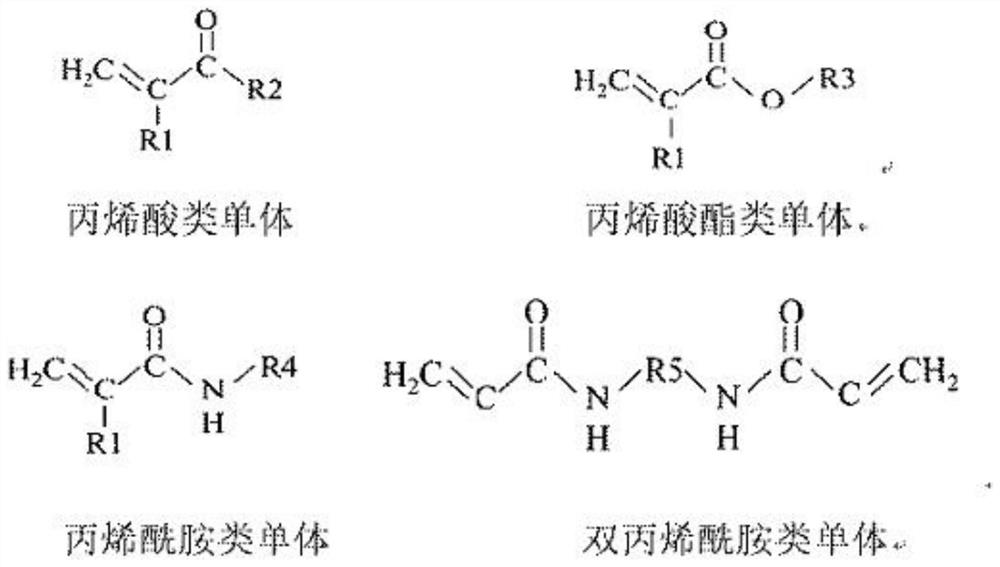

Monomer auto-polymerization assisted synthesized perovskite solar cell and preparation method thereof

A solar cell and self-polymerization technology, which is applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problems of reducing charge extraction and device photoelectric conversion efficiency, poor solubility of macromolecular additives, and difficulty in uniform dispersion of perovskite. , to facilitate the development of commercial applications, inhibit the formation of lead-rich and cesium-rich impurity phases, and increase the viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

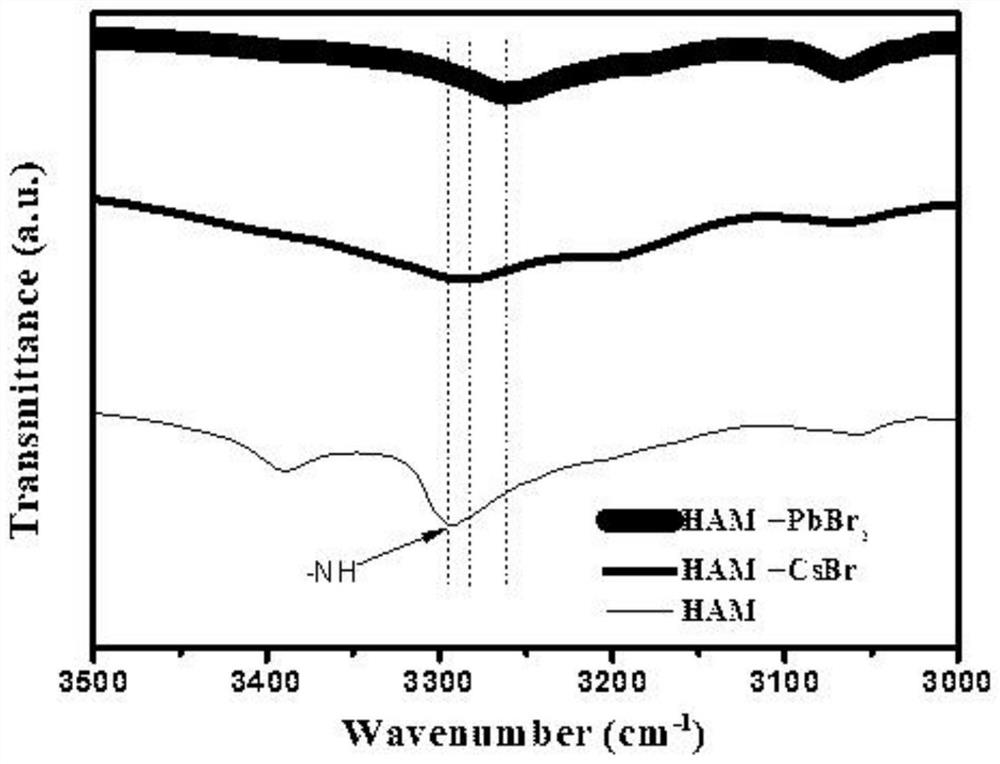

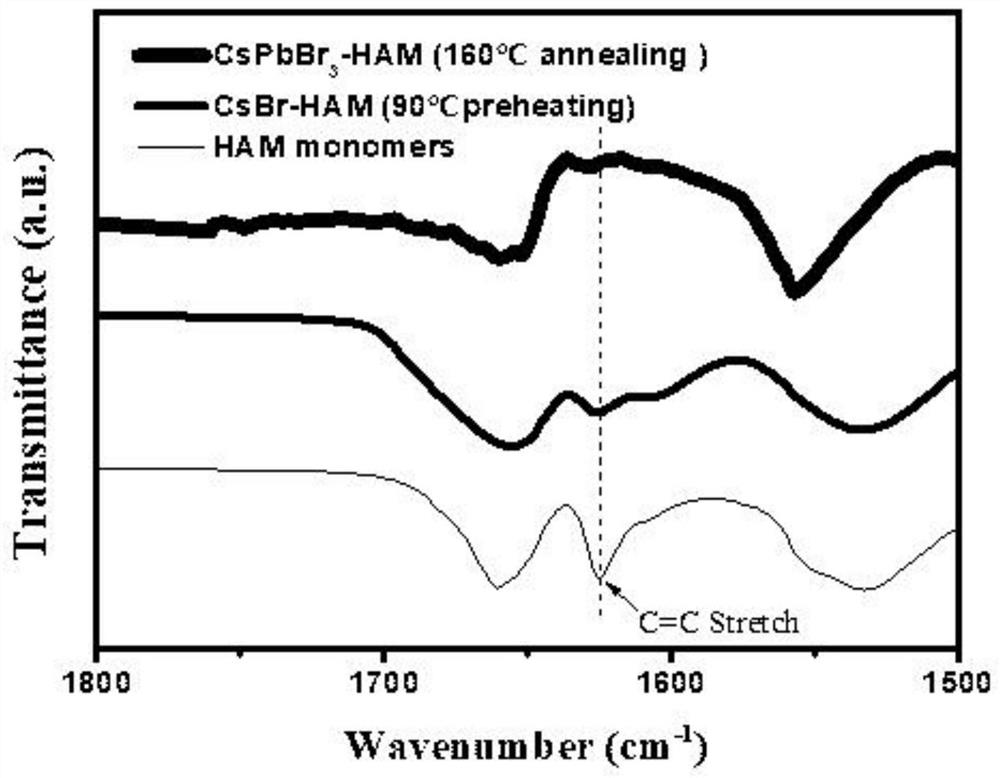

Method used

Image

Examples

Embodiment 1

[0030] 1. Prepare 0.5mol / L ethanol solution of isopropyl titanate, prepare 0.1g / mL titanium dioxide slurry, prepare 0.04mol / L titanium tetrachloride aqueous solution, and prepare DMF solution with a concentration of 1mol / L lead bromide , to prepare an aqueous solution of 250 mg / mL cesium bromide added with a concentration of 0.25 mg / mL N-methylolacrylamide;

[0031] 2. Spin-coat 90 microliters of the isopropyl titanate ethanol solution on the FTO conductive glass for 30 seconds (rotating speed is 7000 rpm) and calcinate at 550° C. for 2 hours to obtain a dense layer of titanium dioxide; After 1 liter of the titanium dioxide slurry was spin-coated on the dense layer of titanium dioxide for 30 seconds (3000 rpm) and calcined at 450° C. for 60 minutes, the titanium dioxide mesoporous layer was obtained; the titanium dioxide mesoporous layer was soaked in the tetrachloride Put in titanium dioxide solution for 30 minutes, heat in a water bath at 75°C, wash and then calcinate at 450...

Embodiment 2

[0036] 1. Prepare 0.5mol / L ethanol solution of isopropyl titanate, prepare 0.1g / mL titanium dioxide slurry, prepare 0.04mol / L titanium tetrachloride aqueous solution, and prepare DMF solution with a concentration of 1mol / L lead bromide , to prepare an aqueous solution of 250 mg / mL cesium bromide added with a concentration of 0.5 mg / mL N-methylolacrylamide;

[0037] 2. Spin-coat 90 microliters of the isopropyl titanate ethanol solution on the FTO conductive glass for 30 seconds (rotating speed is 7000 rpm) and calcinate at 550° C. for 2 hours to obtain a dense layer of titanium dioxide; After 1 liter of the titanium dioxide slurry was spin-coated on the dense layer of titanium dioxide for 30 seconds (3000 rpm) and calcined at 450° C. for 60 minutes, the titanium dioxide mesoporous layer was obtained; the titanium dioxide mesoporous layer was soaked in the tetrachloride Put in titanium dioxide solution for 30 minutes, heat in a water bath at 75°C, wash and then calcinate at 450°...

Embodiment 3

[0042] 1. Prepare 0.5mol / L ethanol solution of isopropyl titanate, prepare 0.1g / mL titanium dioxide slurry, prepare 0.04mol / L titanium tetrachloride aqueous solution, and prepare DMF solution with a concentration of 1mol / L lead bromide , to prepare an aqueous solution of 250 mg / mL cesium bromide added with a concentration of 0.75 mg / mL N-methylolacrylamide;

[0043] 2. Spin-coat 90 microliters of the isopropyl titanate ethanol solution on the FTO conductive glass for 30 seconds (rotating speed is 7000 rpm) and calcinate at 550° C. for 2 hours to obtain a dense layer of titanium dioxide; After 1 liter of the titanium dioxide slurry was spin-coated on the dense layer of titanium dioxide for 30 seconds (3000 rpm) and calcined at 450° C. for 60 minutes, the titanium dioxide mesoporous layer was obtained; the titanium dioxide mesoporous layer was soaked in the tetrachloride Put in titanium dioxide solution for 30 minutes, heat in a water bath at 75°C, wash and then calcinate at 450...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Short circuit current density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com