Heavy oil pre-hydrogenation viscosity reduction catalyst for coal-oil co-processing and preparation method thereof

A catalyst, pre-hydrogenation technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc. Cost, less addition, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method for a heavy oil pre-hydrogenation viscosity-reducing catalyst for kerosene co-refining, the method comprising the steps of:

[0036] In a 500ml stirred tank, add 0.05mol ammonium molybdate to the mixed solution containing 0.04mol di-n-butylamine, 0.1mol tetrahydronaphthalene and 0.01mol polyethylene glycol, and raise the temperature of the stirred tank to 60°C under normal pressure. React for 30 minutes. Lower the temperature of the stirred tank to room temperature, add 0.05 mol carbon disulfide and 0.05 mol thioacetamide, then fill the stirred tank with nitrogen to a pressure of 0.1 MPa at room temperature, seal the stirred tank, raise the temperature to 90°C, and react for 4 hours. After the reaction, the reaction product was filtered, washed with 5 mol of toluene, and dried at 110° C. under a vacuum of 1 kPa to obtain a catalyst (code CAT1) with a yield of 78% and a Mo content of 25%.

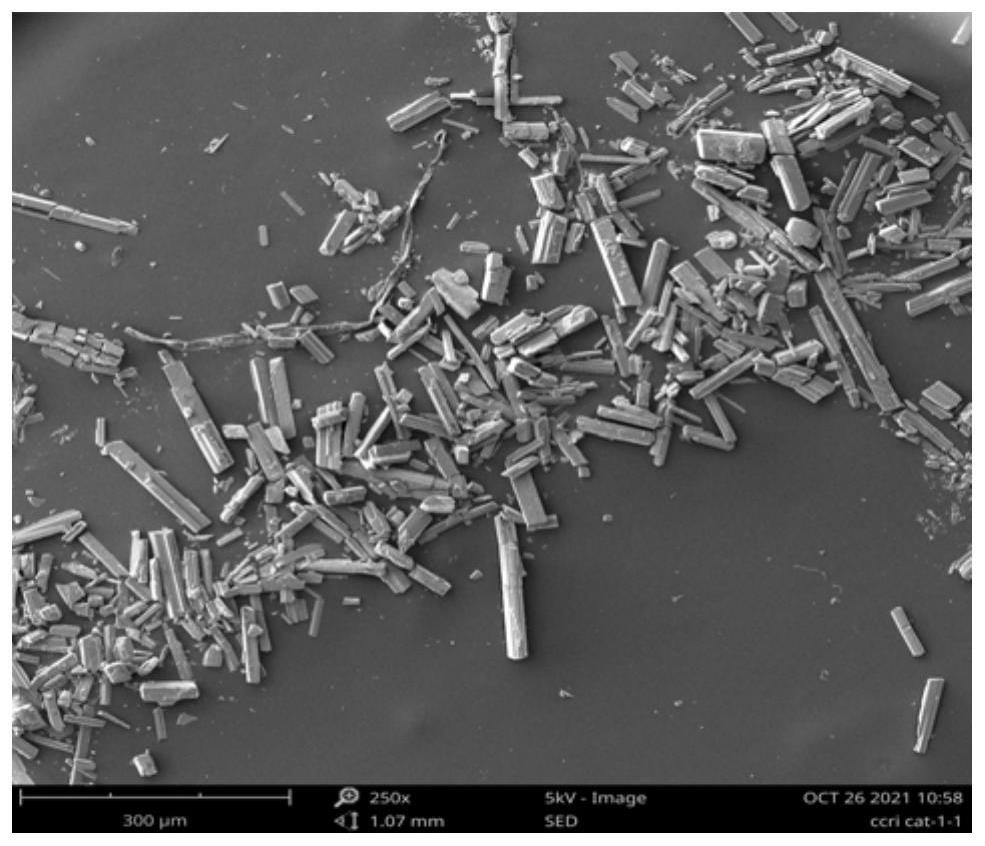

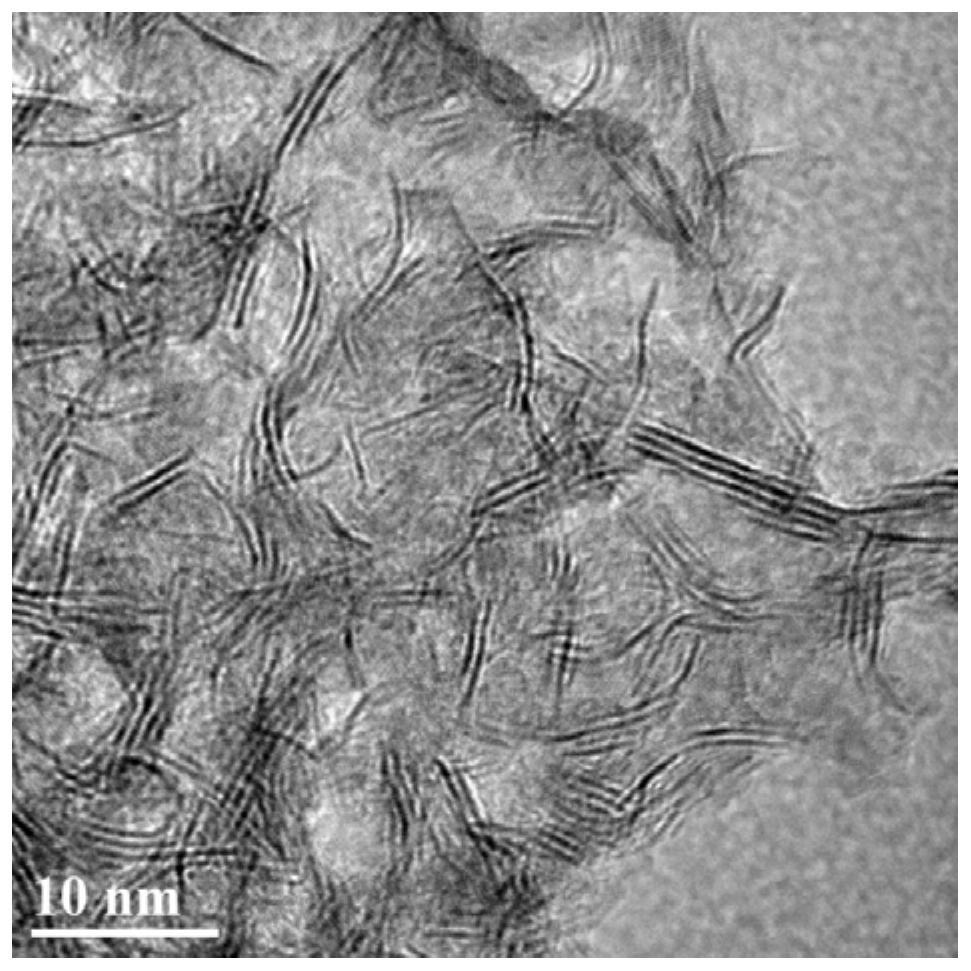

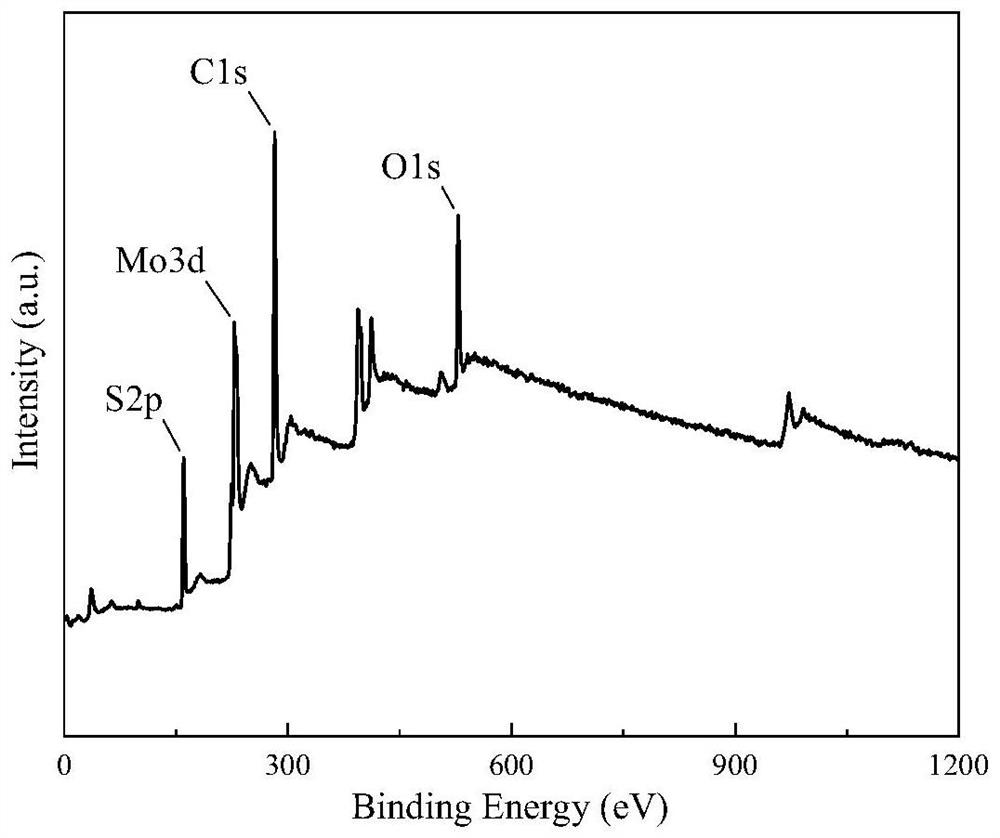

[0037] The scanning electron microscope image of the cataly...

Embodiment 2

[0041] A preparation method for a heavy oil pre-hydrogenation viscosity-reducing catalyst for kerosene co-refining, the method comprising the steps of:

[0042] In a 500ml stirred tank, add 0.05mol sodium molybdate to the mixed solution of 0.04mol diisooctylamine, 0.3mol toluene and 0.01mol methyl oleate, raise the temperature of the stirred tank to 80°C, under the condition of nitrogen protection under normal pressure Reaction 60min. Lower the temperature of the stirred tank to room temperature, add 0.05mol carbon disulfide and 0.05mol sodium sulfide, seal the stirred tank, raise the temperature to 120°C, and react for 6h. After the reaction, the reaction product was filtered, washed with 5 mol methanol aqueous solution, and dried at 110° C. under a vacuum of 1 kPa to obtain a catalyst (number CAT2) with a yield of 80% and a Mo content of 27%.

Embodiment 3

[0044] A preparation method for a heavy oil pre-hydrogenation viscosity-reducing catalyst for kerosene co-refining, the method comprising the steps of:

[0045] In a 500ml stirred tank, add 0.03mol sodium molybdate and 0.03mol ammonium molybdate to the mixed solution of 0.05mol di-n-butylamine, 0.5mol n-tetradecane and 0.02mol polyethylene glycol monomethyl ether, and stir The temperature of the kettle was raised to 80° C., and the reaction was carried out for 60 minutes under the protection of nitrogen under normal pressure. Lower the temperature of the stirred tank to room temperature, add 0.05 mol carbon disulfide and 0.05 mol sodium sulfide, fill the tank with nitrogen to a pressure of 0.1 MPa at room temperature, seal the stirred tank, raise the temperature to 100°C, and react for 5 hours. After the reaction, the reaction product was filtered, washed with 5 mol xylene and ethanol successively, and dried at 110° C. under a vacuum of 1 kPa to obtain a catalyst (code CAT3) w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com