Determination method and determination kit for ultra-trace metal impurities in high-silicon matrix solvent

A metal impurity, ultra-trace technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

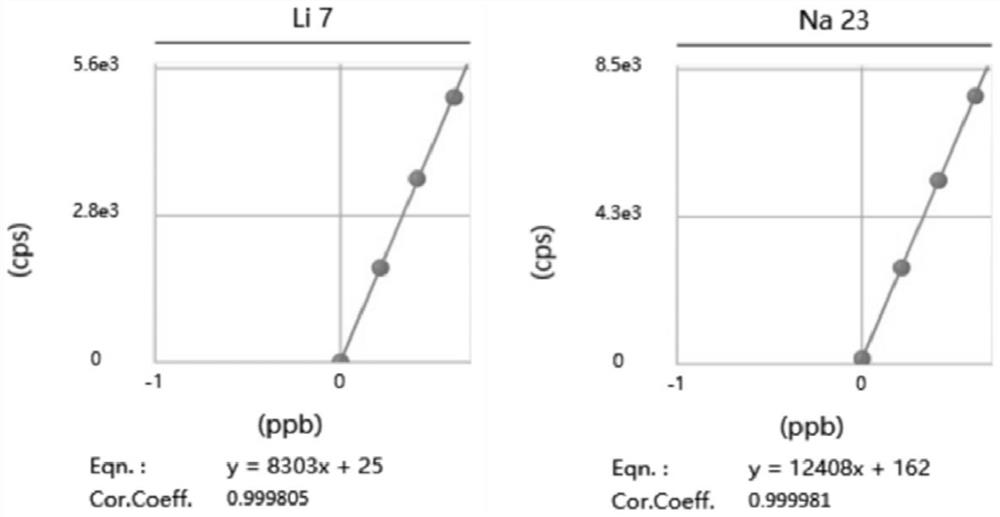

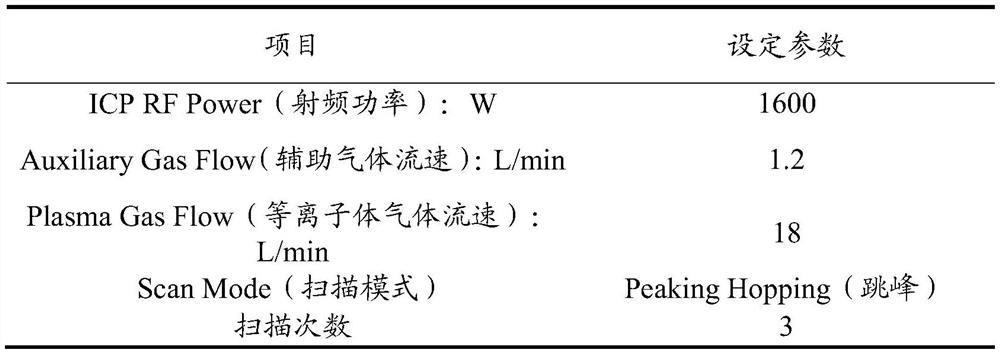

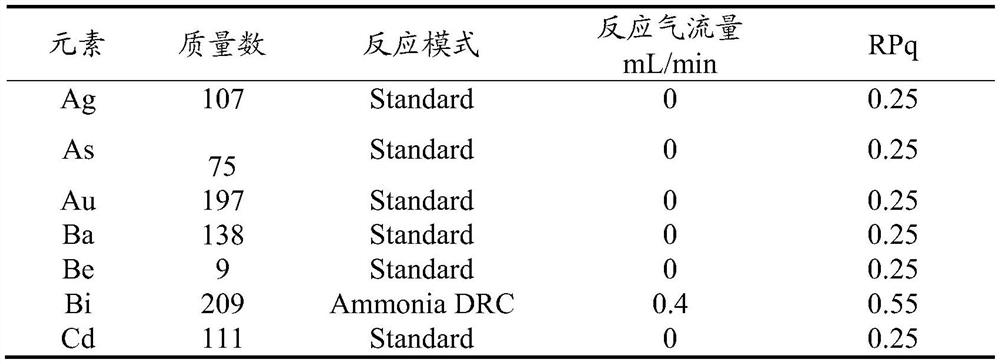

Image

Examples

Embodiment 1

[0032] Determination method of metal impurities in hexafluorodisilane, metal impurities to be tested are Ag (silver), As (arsenic), Au (gold), Ba (barium), Be (beryllium), Bi (bismuth), Cd (cadmium) , Fe (iron), Ge (germanium), In (indium), K (potassium), Li (lithium), Mo (molybdenum), Na (sodium), Ni (nickel), Pb (lead), Pt (platinum) , Sb (antimony), Sn (tin), Sr (strontium), Ta (tantalum), Ti (titanium), Tl (thallium), W (tungsten), Zn (zinc), Zr (pick), the impurity limit is 100ppt.

[0033] 1. Solution preparation

[0034] ①Sample solution Weigh 50g of hexachlorodisilane sample into a clean PFA bottle in an ultra-clean bench, and accurately weigh to 0.0001g. Place the PFA bottle on a heating plate and heat at 180°C until the solution in the PFA bottle is completely evaporated to dryness. After cooling to room temperature, 10 mL of diluent (2% aqueous nitric acid) was added for dissolution. Prepare 3 copies in parallel.

[0035] ②The blank solution is the same as ① ex...

Embodiment 2

[0057] In order to further compare the hydrofluoric acid desiliconization method of the prior art with the evaporation desiliconization method of the present invention, the contriver gets the organic solvent containing silane, measures the silicon content and several susceptible environments and artificially with these two kinds of methods respectively Factors Contamination of metal impurities (K, Na, Zn).

[0058] Take the silane-containing organic solvent and record it as it is. Take the original samples and prepare 3 parts of sample solutions (same as Example 1), which are recorded as 1# sample evaporated to dryness, 2# sample evaporated to dryness, and 3# sample evaporated to dryness. In order to prevent ICP-MS from being polluted by excessive silicon content, ICP-OES (inductively coupled plasma optical emission spectrometer) was used to detect Si (silicon). At the same time, the inventor removed silicon by adding hydrofluoric acid digestion method, took the original samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com