Composite molecular sieve as well as preparation method and application thereof

A composite molecular sieve and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, hydrocarbons, etc., can solve problems such as low atom utilization, poor cycle performance, and small effective active surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The application also provides a preparation method for a composite molecular sieve, comprising the following steps:

[0029] Mix the structure directing agent, silicon source and water, and heat to obtain the initial sol;

[0030] crystallizing the initial sol, transition metal salt and mineralizer to obtain a solid product;

[0031] The solid product is calcined to obtain a composite molecular sieve.

[0032] In the process of preparing the composite molecular sieve, the applicant first mixes the structure-directing agent, silicon source and water, and heats to obtain the initial sol; during this process, the above-mentioned raw materials synthesize the molecular sieve precursor. The structure directing agent is a nitrogen-containing organic compound containing a tertiary amine center or a quaternary ammonium center; in a specific embodiment, the structure directing agent is specifically selected from tetrapropylammonium hydroxide, tetrapropylammonium bromide or pyrid...

Embodiment 1

[0043] Weigh 3.22g tetrapropylammonium hydroxide, 4.91g tetraethyl orthosilicate and 4.55g H 2 After mixing O, stir at a constant temperature of 50°C for 14h at a speed of 350r / min to obtain a molecular sieve precursor; weigh 0.23g Fe(NO 3 ) 3 9H 2 O was added to the precursor, transferred to a hydrothermal kettle for crystallization at 160 °C for 28 h; the crystallized sample was washed until the pH was less than 8, and dried at 80 °C for 14 h; finally, the sample was calcined at 500 °C for 3 h to obtain Fe-MFI catalyst A.

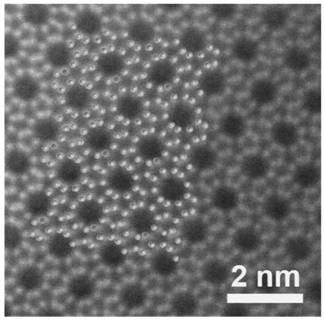

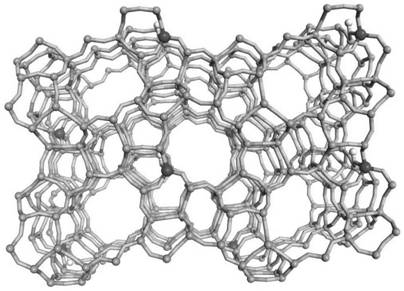

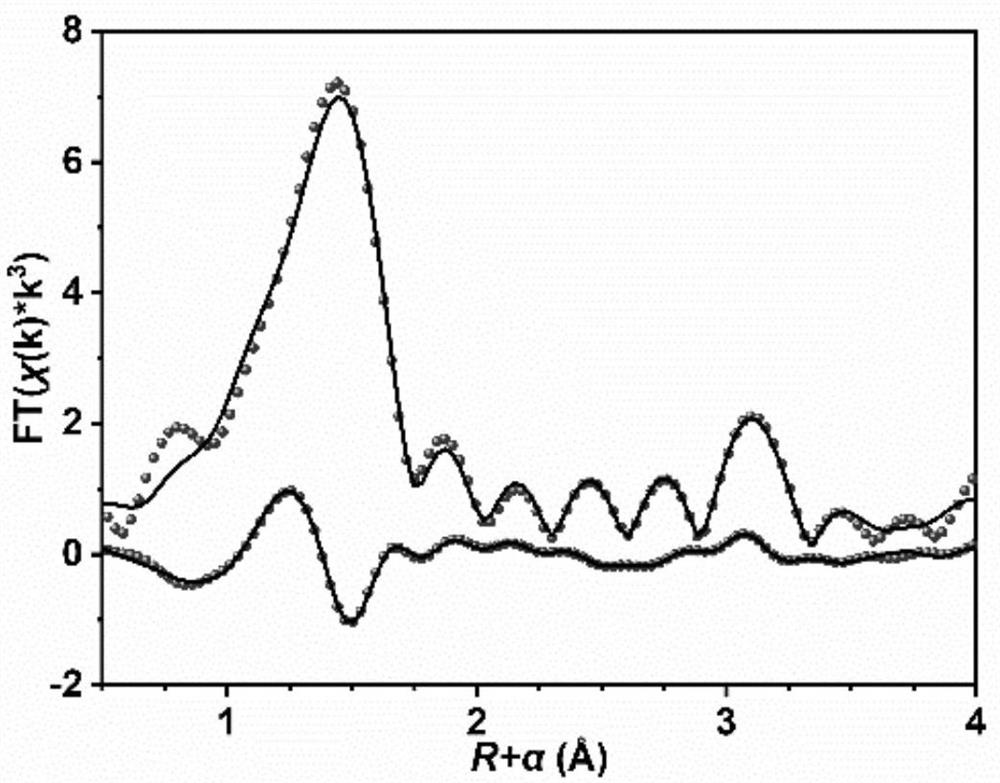

[0044] figure 1 The EXAFS result (dotted line) of the composite molecular sieve prepared for the present embodiment and the theoretical calculation fitting result (solid line) contrast graph; figure 2 The spherical aberration electron microscope picture (wherein the red dot is skeleton Fe) of the composite molecular sieve prepared for the present embodiment; figure 1 and figure 2 It can be explained that the transition metal Fe in the composite mol...

Embodiment 2

[0046] Weigh 4.05g tetrapropylammonium bromide, 5.32g gaseous silicon dioxide and 5.89g H 2 After mixing O, stir at a constant temperature of 70°C for 12h at a speed of 450r / min to obtain a molecular sieve precursor; weigh 0.59g of CuSO 4 ·5H 2 O was added to the precursor, transferred to a hydrothermal kettle for crystallization at 170 °C for 25 h; the crystallized sample was washed to pH less than 8, and dried at 85 °C for 13 h; finally, the sample was calcined at 560 °C for 2.5 h to obtain Cu-*BEA catalyst B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com