Isosorbide derivative and nest and fissure sealing agent based on isosorbide structure

A pit and fissure sealing and isosorbide technology, which is applied in the field of medical oral biomaterials, can solve the problems of high price, staying, and increasing the cost of patient treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

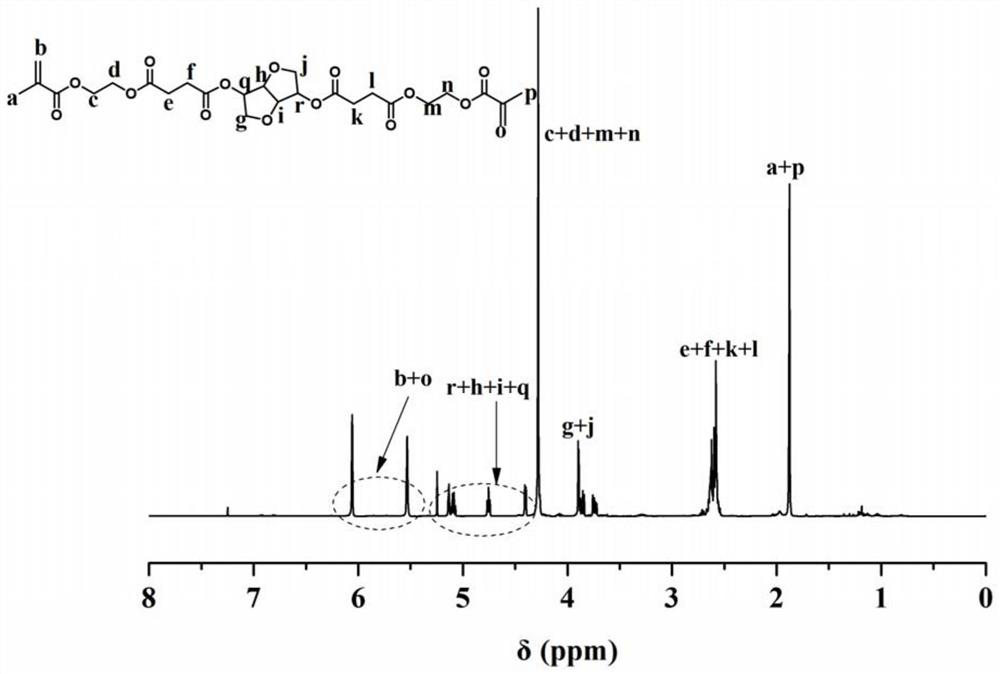

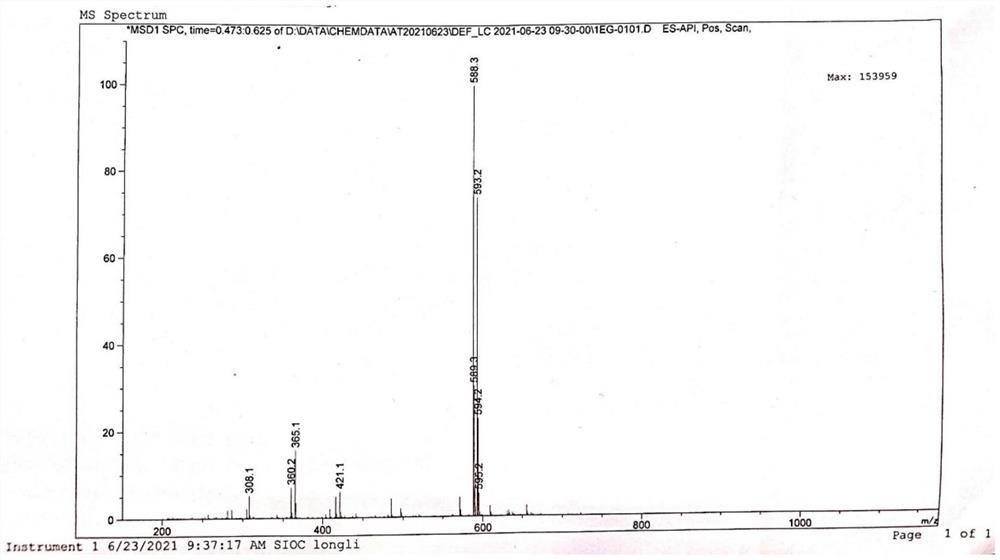

[0047] Example 1: Preparation of isosorbide-based matrix isosorbide-bis{succinic acid mono[2-[(2-methyl-acryloyl)oxy]ethyl]ester} ester (HEMA-ISO-HEMA)

[0048]

[0049] Add 1-ethyl-(3-dimethylaminopropyl)carbodiimide hydrochloride (EDC.HCl, 23.61g, 0.123mol) to the 1000mL three-necked flask with a stirring bar, dichloromethane (DCM, 500mL), triethylamine (Et 3 N, 24.92g, 0.246mol) and triethylaminosuccinic acid mono[2-[(2-methyl-acryloyl)oxy]ethyl] ester 2 (23.63g, 0.102mol), after stirring for 30min, add isosorbide 1 (5 g, 0.034 mol) and 4-dimethylaminopyridine (DMAP, 0.84 g, 0.0068 mol).

[0050] A reflux condenser was connected to the reaction bottle, and the temperature was raised to about 45°C for reflux reaction for 24 hours. Stop the reaction, wash the reaction solution with water and saturated sodium bicarbonate solution, separate the organic phase, and dry it with anhydrous sodium sulfate until the liquid becomes clear. After suction filtration, the filtrate wa...

Embodiment 2

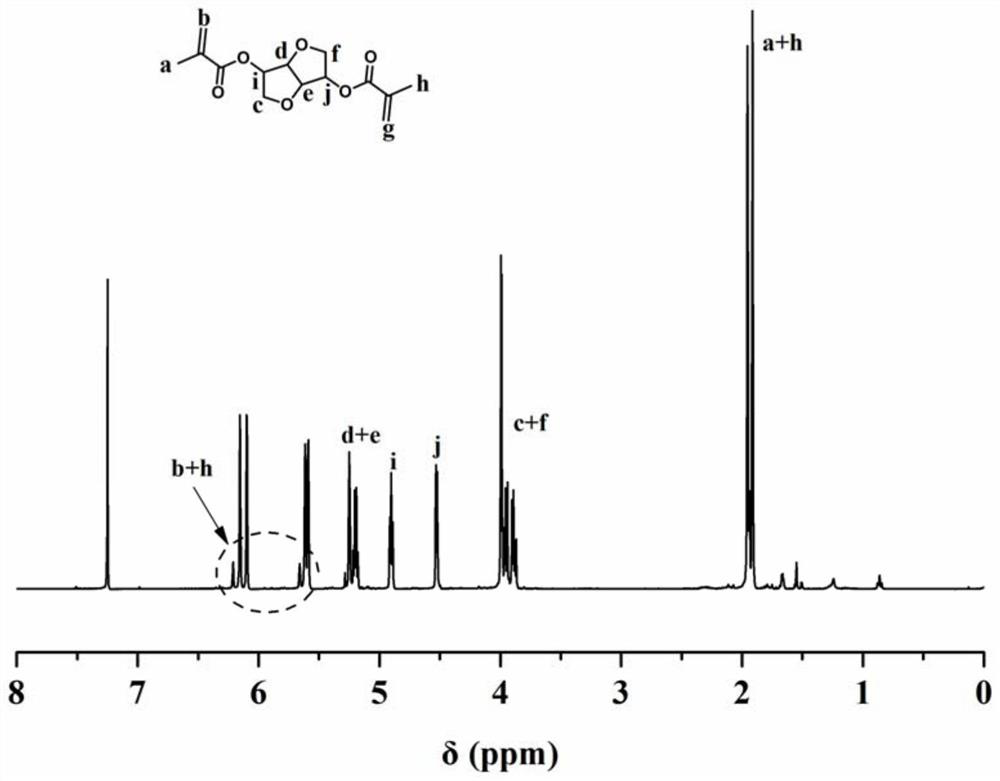

[0053] Example 2: Preparation of isosorbide-based diluent isosorbide-bismethacrylate (IBM)

[0054]

[0055] Isosorbide (5.01g, 0.034mol), Et 3 N (14.56g, 0.144mol) and DMAP (0.42g, 3.4mmol) were added to a 250mL three-necked bottle with a pre-magnetic sub, and 30mL anhydrous CH 2 Cl 2 Stir to dissolve. The reaction flask was placed in an ice-water bath at 0°C, and methacryloyl chloride (11.92 g, 0.114 mol) was slowly added dropwise. After the dropwise addition, the reaction temperature naturally returned to room temperature, and the reaction was carried out overnight.

[0056] Add water to quench the reaction, separate the organic phase, CH 2 Cl 2 Extract the aqueous phase once. Combine the organic phases with anhydrous Na 2 SO 4 After drying, it was spin-dried, and after silica gel column chromatography (eluent: n-hexane / dichloromethane / methanol (v / v / v=100 / 300 / 5)), 5.14g of transparent colorless liquid product IBM was obtained, yield 53.55 %. Product of IBM 1 H...

Embodiment 3

[0059] Example 3: Silanization modification of dental glass powder

[0060] Prepare 50mL of 60% ethanol-water solution, adjust the pH to 3-4 with acetic acid, add 1g of γ-MPS and stir evenly, then add 10g of glass powder, stir at room temperature for 1h, and heat at 70°C for 1h. The solvent was evaporated under reduced pressure at 65-70°C, and the remaining powder mixture was reacted and dried at 120°C. The dried powder was washed with ethanol, centrifuged, and the lower precipitate was vacuum-dried at 40°C. The infrared spectrum of the dental glass powder modified by the silane coupling agent is as follows: Figure 5 shown.

[0061] FT-IR:ν(cm -1 ):2962(=C-H),1726(C=O).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com