Synthesis process and application of hydroxyl-terminated hyperbranched polyphosphazene flame retardant

A technology of hydroxyl-terminated hyperbranching and polyphosphazene, which is applied in the direction of polyurea/polyurethane coatings, coatings, fireproof coatings, etc. To achieve the effects of enhancing thermal stability and heat resistance, inhibiting the reaction process, and enhancing flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

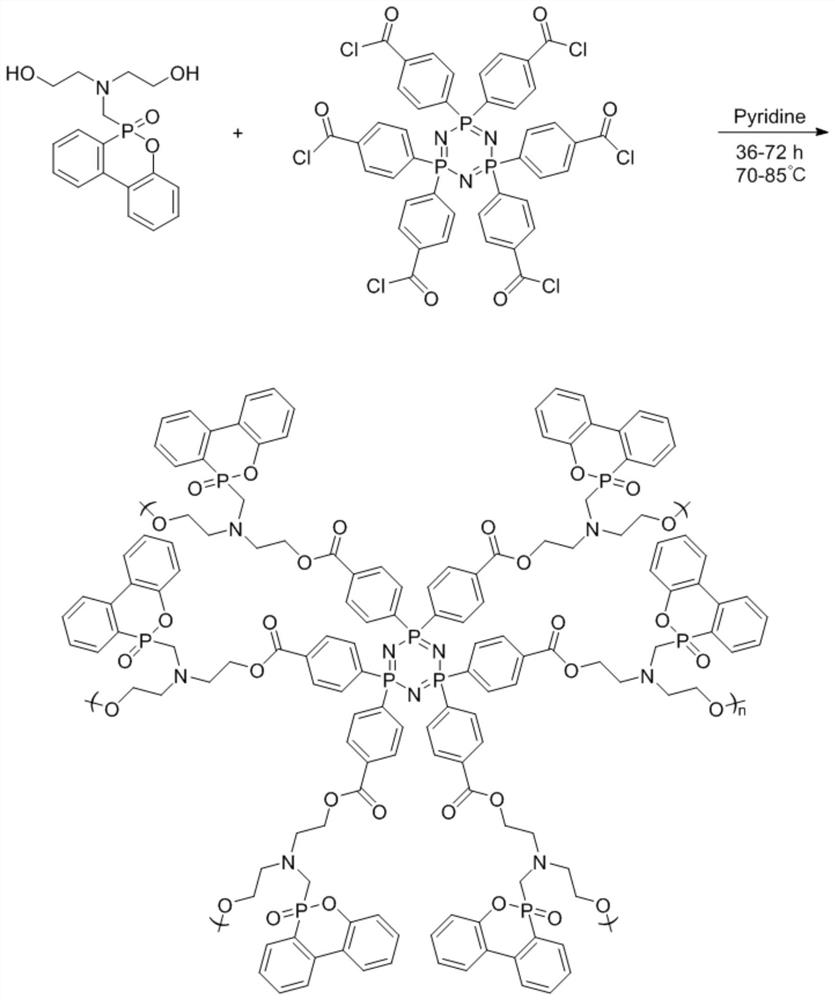

[0029] (1) Add 0.2 g of carboxycyclotriphosphazene to 5 mL of SOCl 2 , pass into N 2 Exhaust the air, heat to 60°C, react for 5 hours, and distill under reduced pressure after the reaction, wash the product with dichloromethane and acetone to obtain cyclotriphosphazene acid chloride.

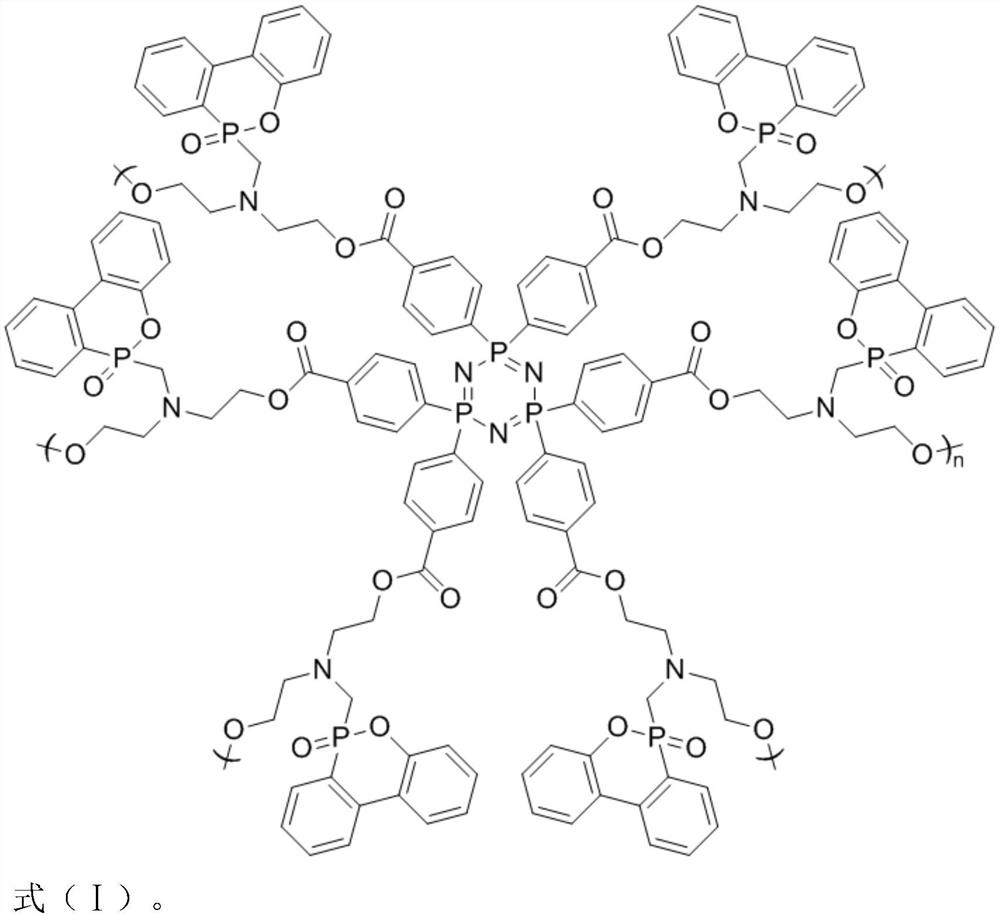

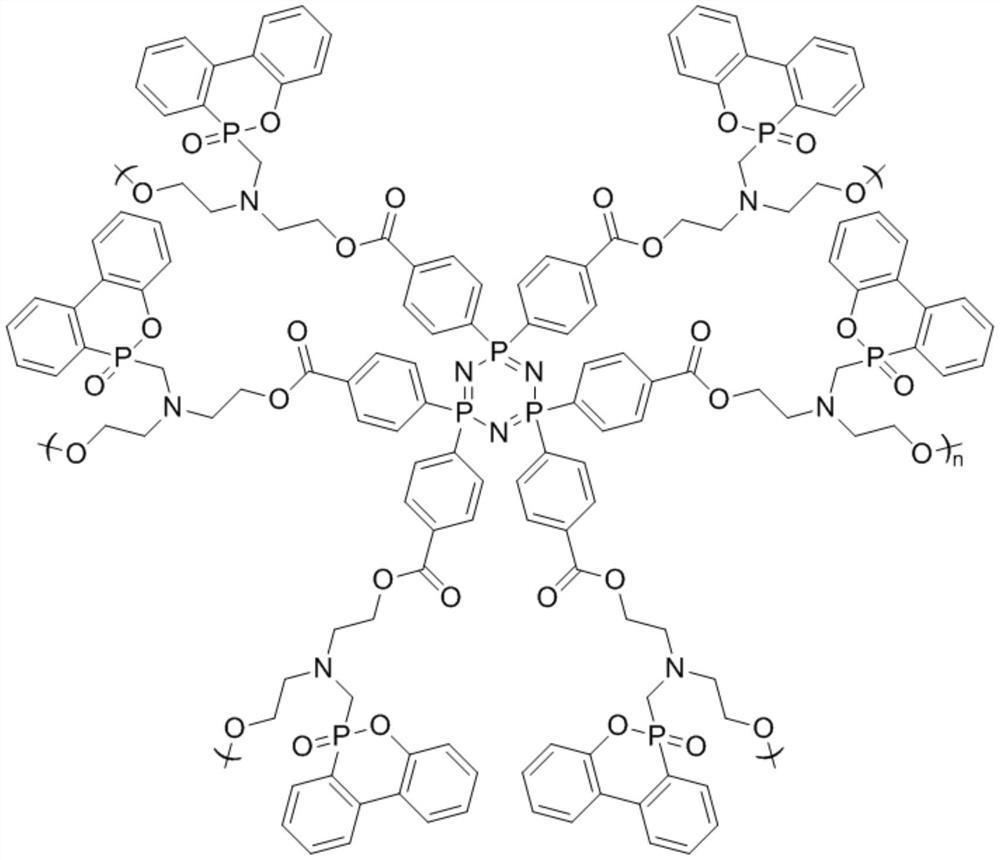

[0030] (2) Add 0.5% of acid chloride cyclotriphosphazene into xylene solvent, stir to dissolve and then pass into N 2 Exhaust air, add 0.83g dihydroxy DOPO derivative (C 17 h 20 NO 4 P), and 0.08g of catalyst pyridine was added dropwise, heated to 70°C, reacted for 36h, cooled after the reaction, and distilled under reduced pressure, and the product was sequentially extracted by tetrahydrofuran, dichloromethane and acetone to obtain a hydroxyl-terminated hyperbranched polyphosphazene flame retardant.

[0031] (3) The diisocyanate monomer of 3g is mixed with the polyether polyol of 5g, and the dibutyltin dilaurate of 0.1g is added dropwise, in N 2 React at 70°C for 2 hours in the atmosphere...

Embodiment 2

[0033] (1) Add 0.2 g of carboxycyclotriphosphazene to 10 mL of SOCl 2 , pass into N 2 Exhaust the air, heat to 70°C, react for 5h, distill under reduced pressure after reaction, wash the product with dichloromethane and acetone, and obtain cyclotriphosphazene acid chloride.

[0034] (2) Add 0.5% of acid chloride cyclotriphosphazene into acetonitrile solvent, stir to dissolve and then pass into N 2 Exhaust air, add 0.9g dihydroxy DOPO derivative (C 17 h 20 NO 4 P), and 0.1g of catalyst pyridine was added dropwise, heated to 85°C, reacted for 36h, cooled after the reaction, and distilled under reduced pressure, and the product was sequentially extracted by tetrahydrofuran, dichloromethane and acetone to obtain a hydroxyl-terminated hyperbranched polyphosphazene flame retardant.

[0035] (3) The diisocyanate monomer of 3.3g is mixed with the polyether polyol of 5g, and the dibutyltin dilaurate of 0.15g is added dropwise, in N 2 React at 70°C in the atmosphere for 2.5h to ob...

Embodiment 3

[0037] (1) Add 0.2 g of carboxycyclotriphosphazene to 15 mL of SOCl 2 , pass into N 2 Exhaust the air, heat to 70°C, react for 8 hours, distill under reduced pressure after the reaction, wash the product with dichloromethane and acetone, and obtain the acid chloride cyclotriphosphazene.

[0038] (2) Add 0.5% of acid chloride cyclotriphosphazene to 1,4 dioxane solvent, stir to dissolve and then pass into N 2 Exhaust the air, add 1 g dihydroxy DOPO derivative (C 17 h 20 NO 4 P), and 0.12g of catalyst pyridine was added dropwise, heated to 80°C, reacted for 48h, cooled after the reaction, and distilled under reduced pressure, and the product was sequentially extracted by tetrahydrofuran, dichloromethane and acetone to obtain a hydroxyl-terminated hyperbranched polyphosphazene flame retardant.

[0039] (3) The diisocyanate monomer of 3.5g is mixed with the polyether polyol of 5g, and the dibutyltin dilaurate of 0.2g is added dropwise, in N 2 React in the atmosphere at 75°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carbon residual rate | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com